3311 specifications

The Beverage-Air 3311 is a top-tier commercial refrigerator meticulously designed to meet the demanding needs of foodservice establishments. Known for its reliability and efficiency, this model is a favorite among restaurant owners, bars, and cafés. The primary focus of the Beverage-Air 3311 is to provide optimal storage conditions for beverages, including soft drinks, juice, and bottled water, ensuring they are kept at ideal temperatures for maximum freshness.One of the standout features of the Beverage-Air 3311 is its spacious interior, which provides ample storage for a variety of beverages. Measuring 33 inches wide, this unit can accommodate multiple shelves, each adjustable to suit the specific height requirements of various bottles and containers. The unit typically comes with sturdy, epoxy-coated wire shelves that not only ensure uniform cooling but also provide resistance against spills and easy cleaning.

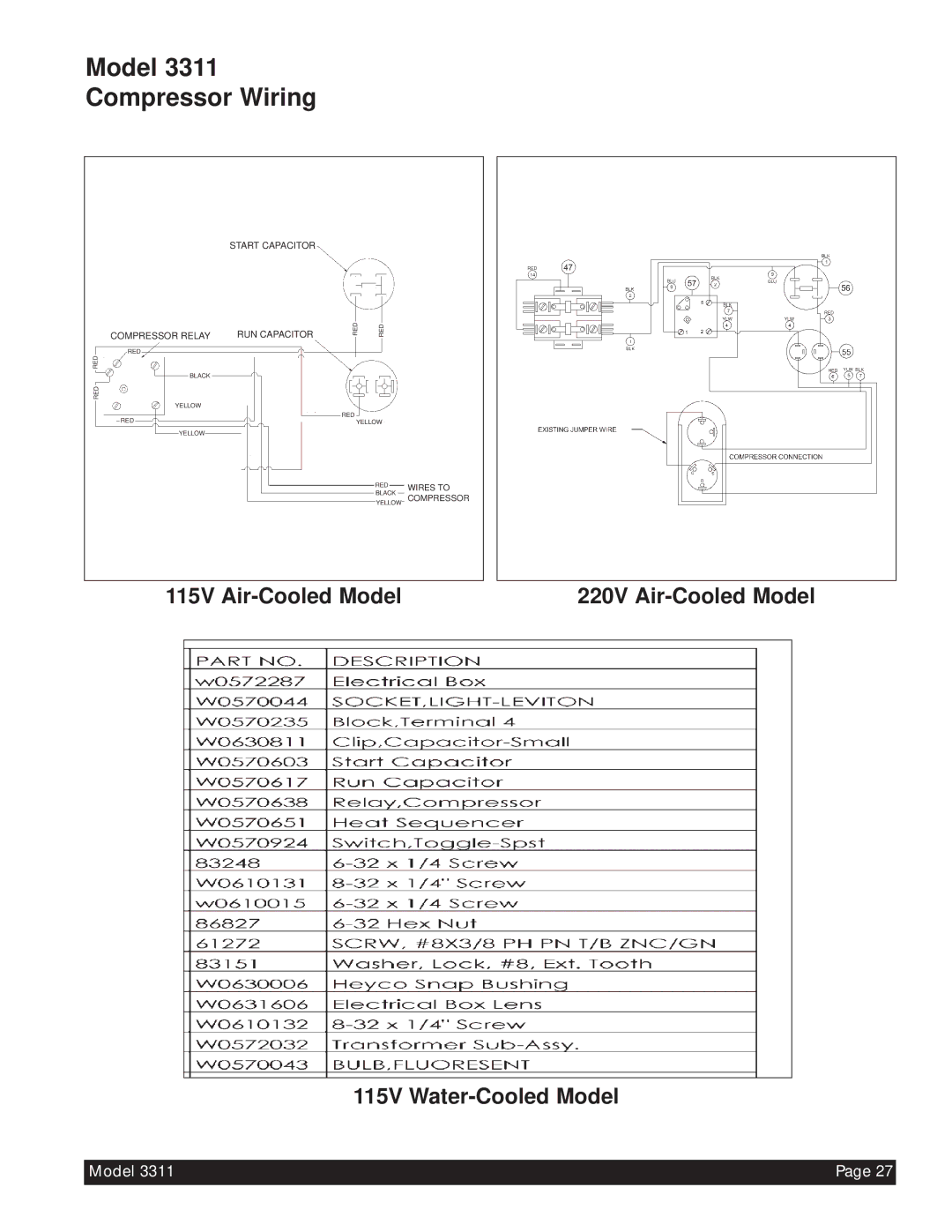

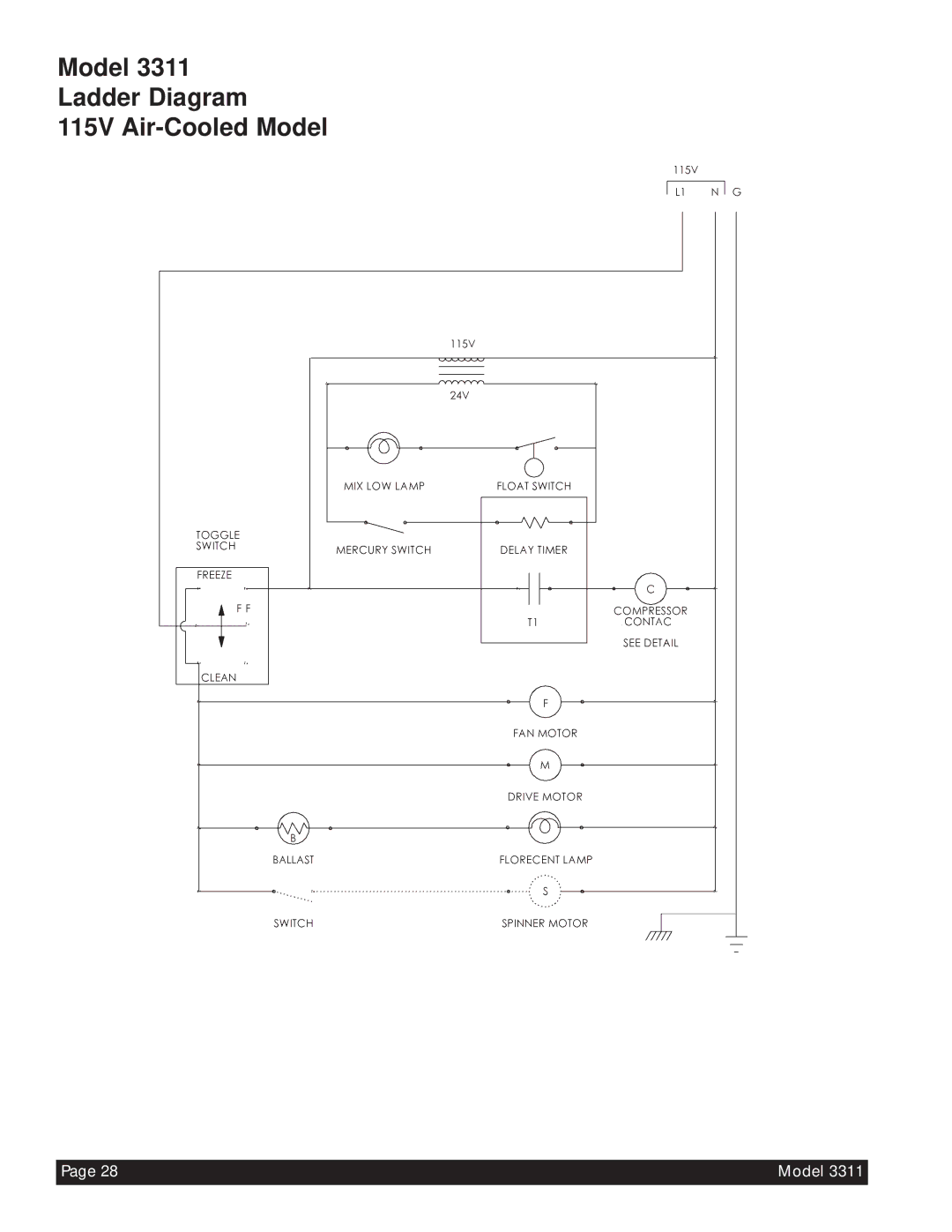

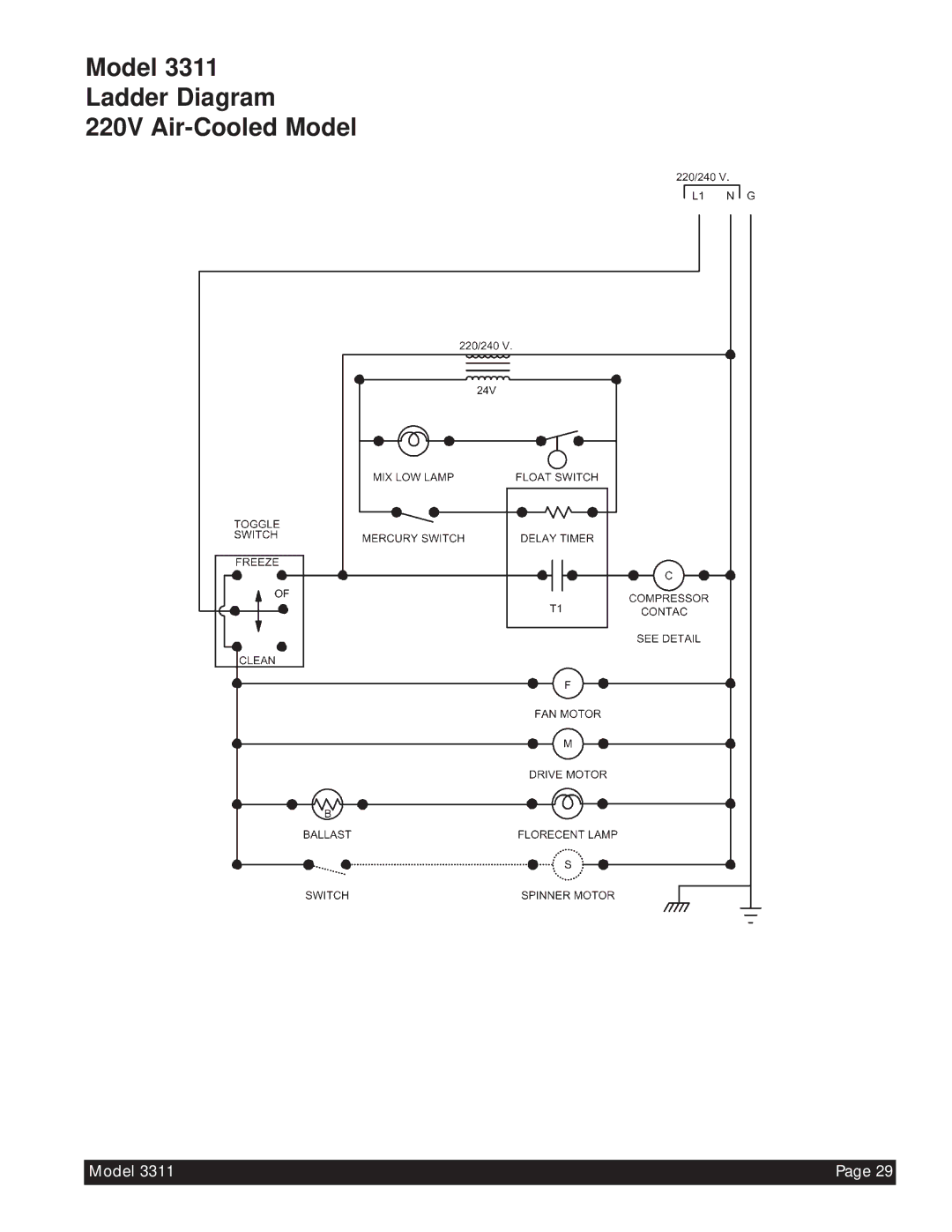

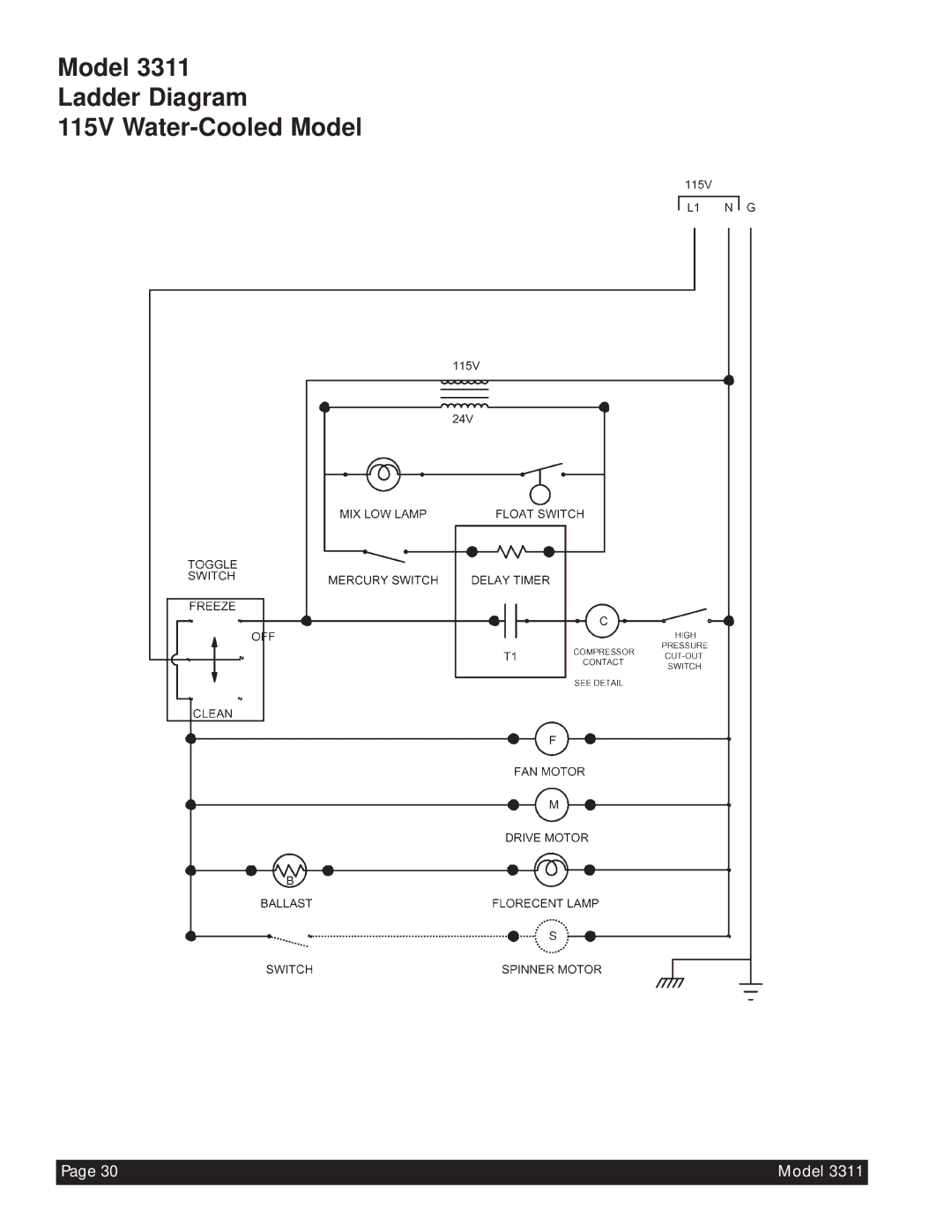

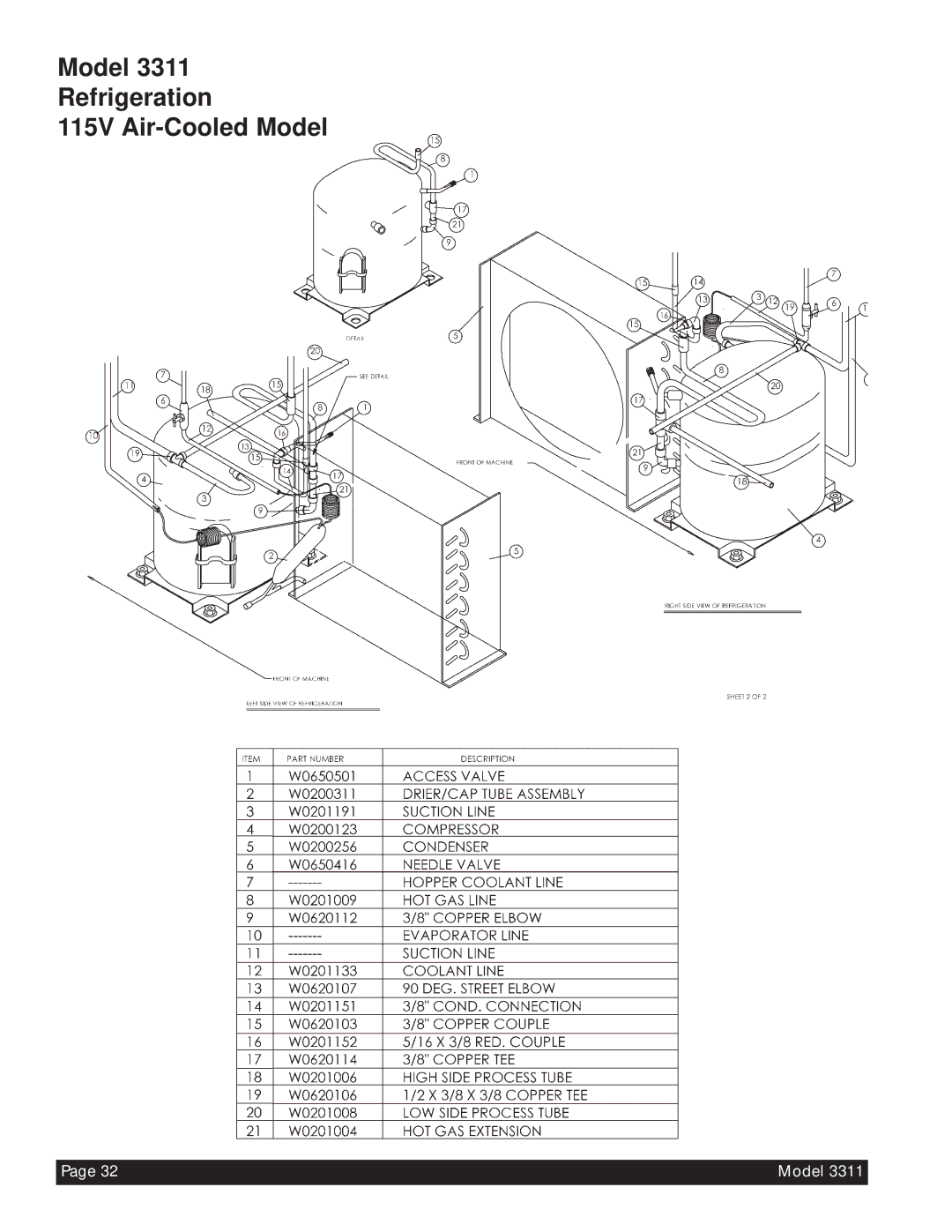

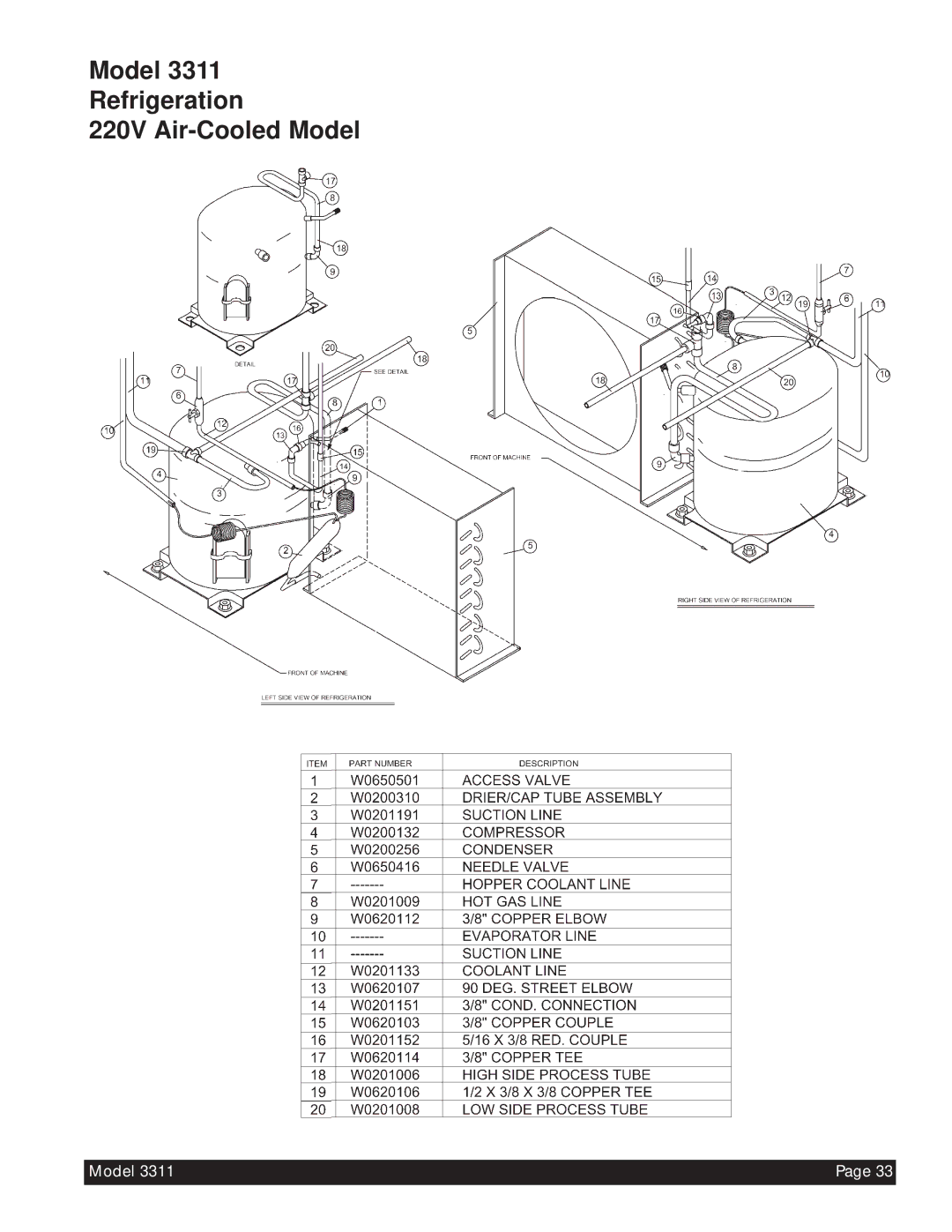

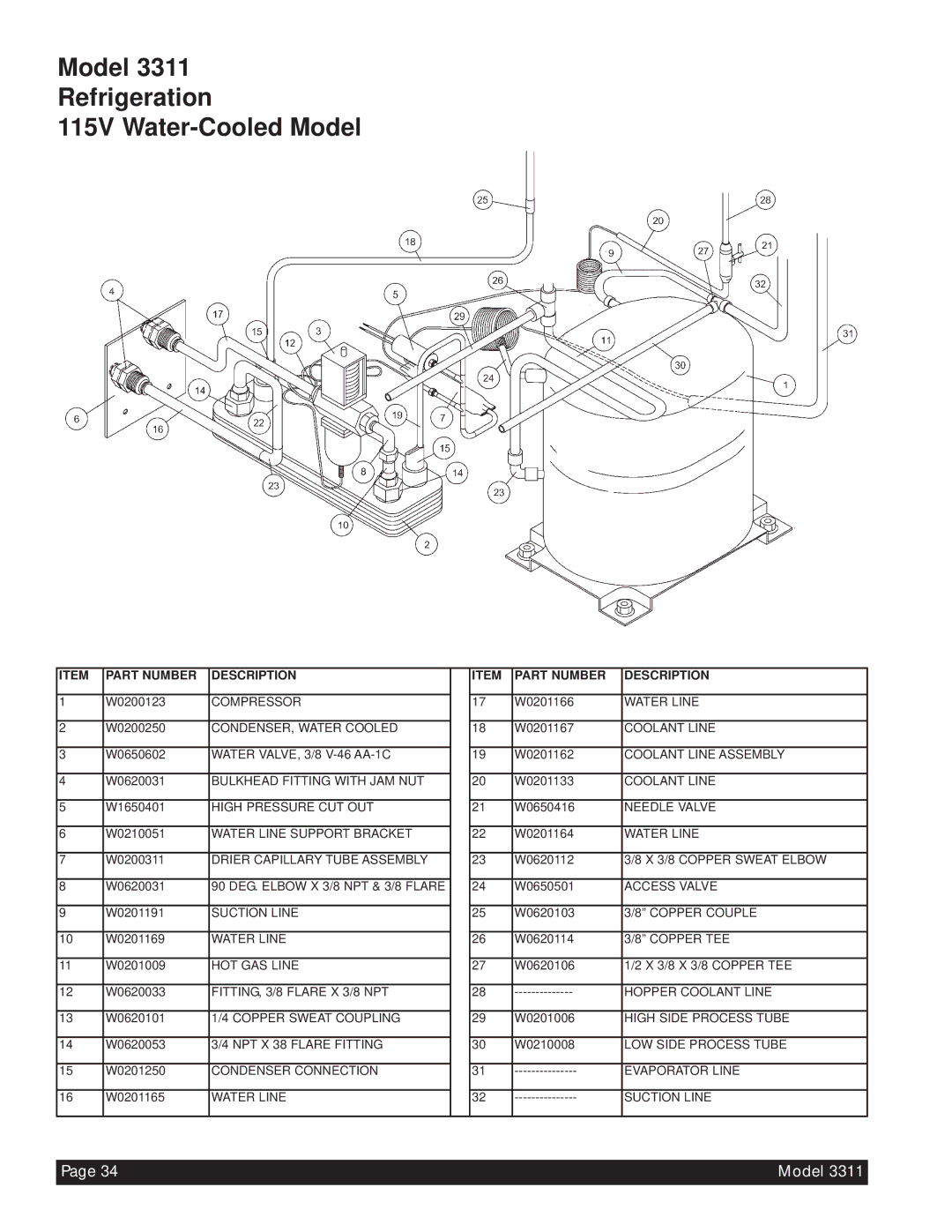

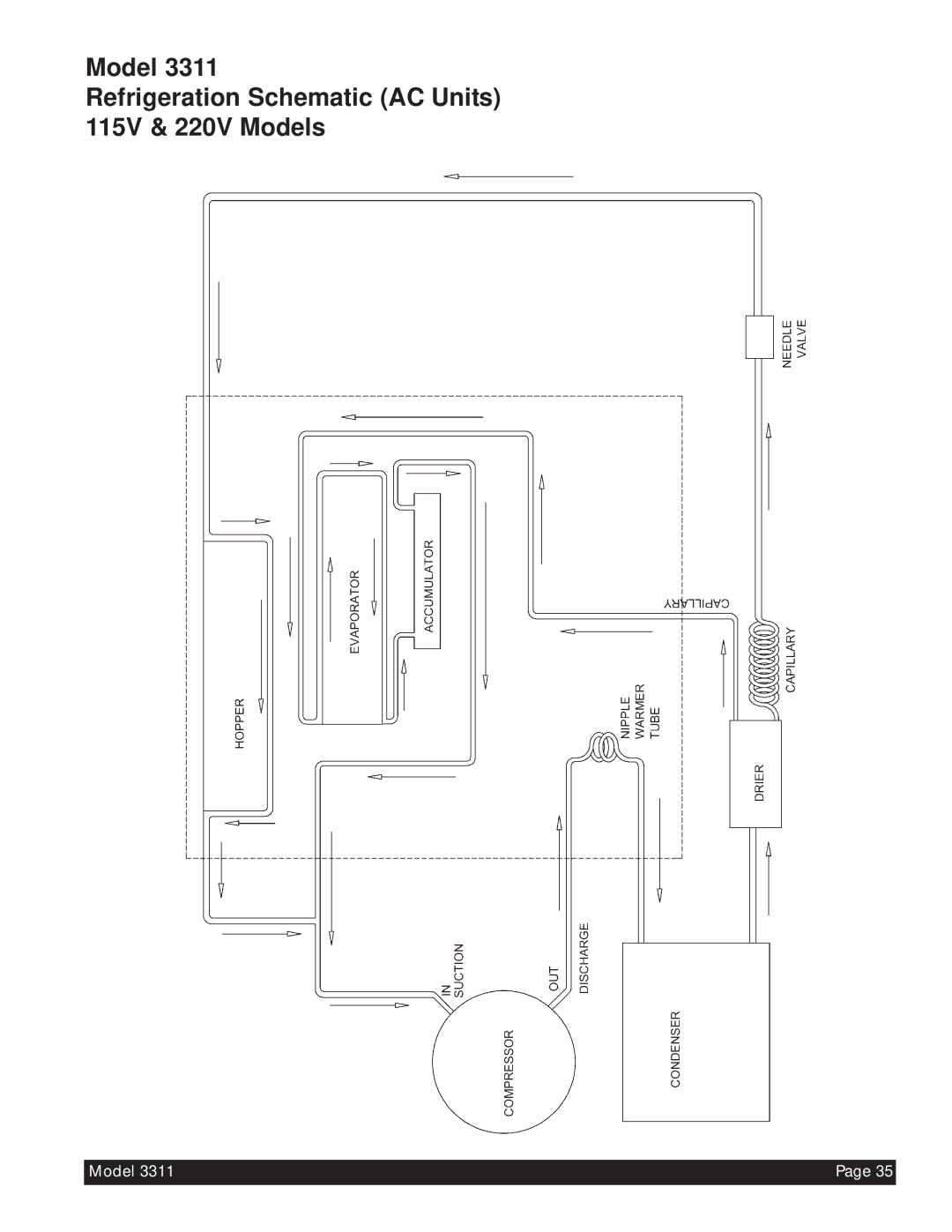

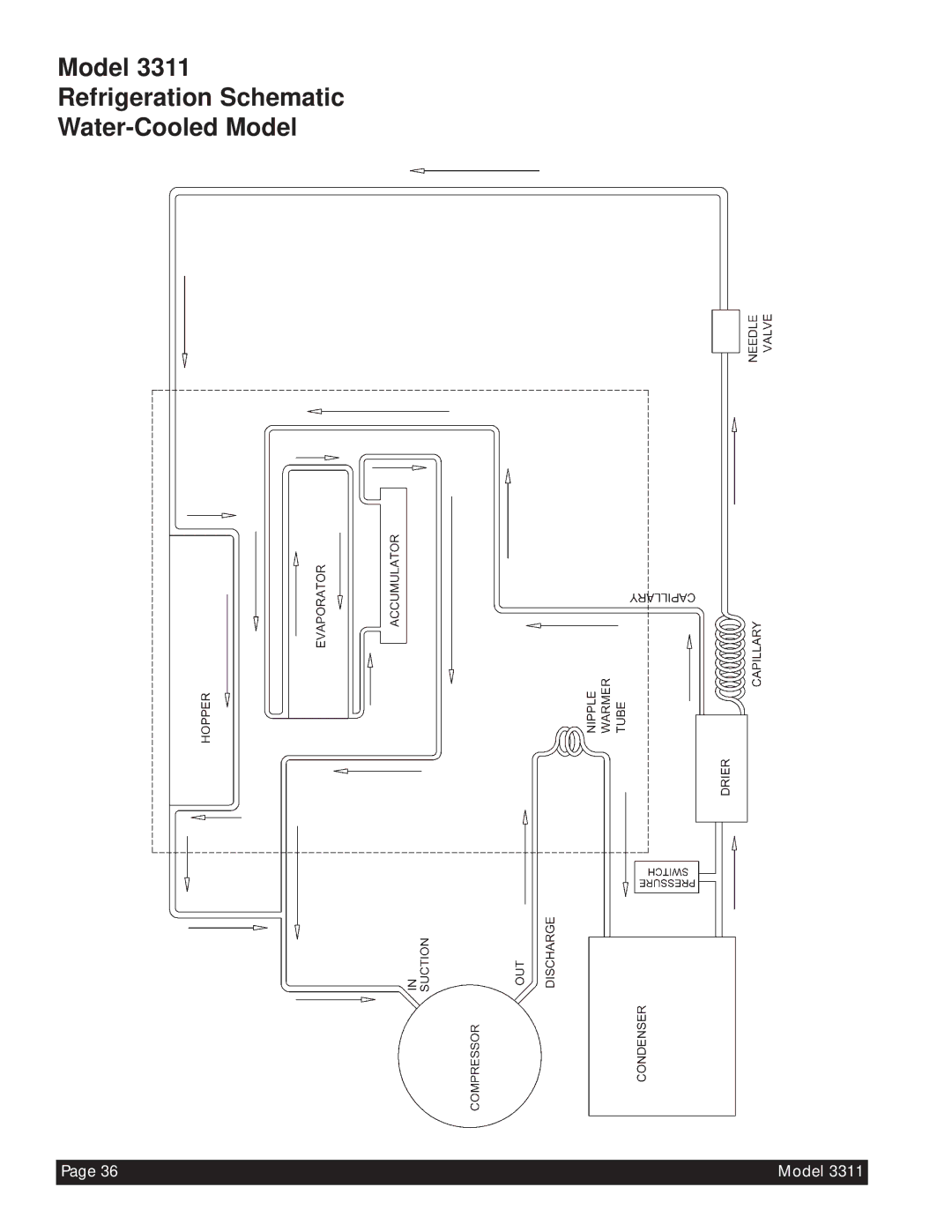

Equipped with a powerful refrigeration system, the Beverage-Air 3311 utilizes environmentally friendly refrigerants, aligning with modern standards for sustainability. The compressor is designed for efficiency, providing rapid cooling and maintaining consistent temperatures across the unit while minimizing energy consumption. This feature is particularly valuable for businesses aiming to reduce operating costs while maintaining high product quality.

The Beverage-Air 3311 also includes a self-closing door with magnetic gaskets, which helps maintain the internal temperature and prevents cold air loss, thereby enhancing energy efficiency. Additionally, the doors are equipped with locks to ensure the security of valuable beverages during off-hours.

For enhanced visibility, the Beverage-Air 3311 can feature a glass door option, allowing customers and staff to easily view the stored products without opening the door. This feature not only improves accessibility but also adds an aesthetic appeal to the display.

In terms of durability, the exterior of the Beverage-Air 3311 is crafted from high-quality stainless steel, providing resistance against rust and corrosion while ensuring an easy-to-clean surface. The interior is designed with seamless construction, which further reduces the chances of bacteria buildup and makes maintenance straightforward.

Overall, the Beverage-Air 3311 combines advanced technology with thoughtful design features, making it an ideal choice for those looking to enhance their beverage service. With its capacity, efficiency, and durability, this commercial refrigerator stands out as a reliable partner in the fast-paced environment of food and beverage service.