LEFT HAND

SIDE SHOWN

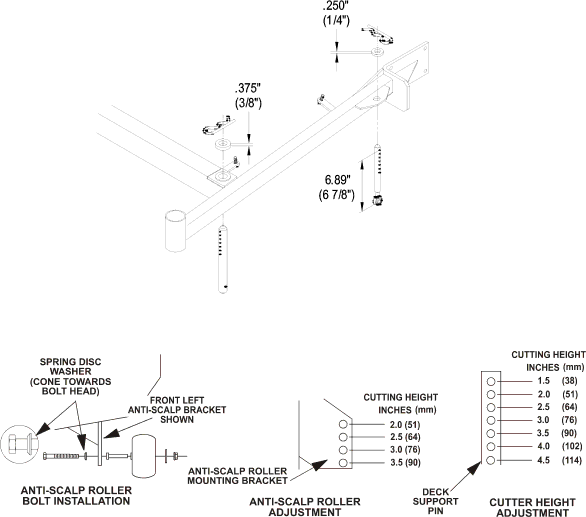

FIGURE 9

CUTTING HEIGHT ADJUSTMENT

FOR CUTTING HEIGHTS ABOVE

3.5” (8.89 CM) USE ![]() THE BOTTOM HOLE

THE BOTTOM HOLE

THE ROLLERS WILL STILL BE ![]() EFFECTIVE AGAINST SCALPING

EFFECTIVE AGAINST SCALPING

FIGURE 10

CUTTING HEIGHT ADJUSTMENT

c)Adjust

For Maximum Deck Flotation, place rollers one hole position lower. Rollers should maintain 1/4 in. (6.4 mm) clearance to ground. Do Not adjust rollers to support the deck. Be sure roller bolts and nuts are installed with the spring disc washer between head of the bolt and mounting bracket.

Torque to

d)When operating in extremely rough conditions it may be necessary to position the

NOTE: When

5.2.2Pump drive belt tension adjustment: No adjustment necessary.

5.2.3Mower deck drive belt: No adjustment necessary.

-31 -