MODEL 2100 OVERHEAD PROJECTOR

SECTION 4 ADJUSTMENTS

GENERAL

The following section describes the adjustments that will be necessary to service the Model 2100 (4100) Overhead Projectors.

TOOLS REQUIRED

A.Screwdriver (standard & phillips)

B.Wrench, open end

C.Pliers, standard

D.Pliers, grip ring

E.Square

F.Torx Driver,

PROJECTOR

Reliable

This requires a permanent viewing screen and test stand in the dealer’s shop, thus enabling high

Only two

The screen should be vertical and can most easily be provided by applying a flat white paint to a 60 by 60 inch area of a smooth wall. If a smooth wall is not available, a piece of wallboard painted flat white, or a white window shade of the proper size, can be mounted in the selected area.

The test stand should be high enough to provide easy access to all parts of the Overhead Projector when the projector is placed on the stand for

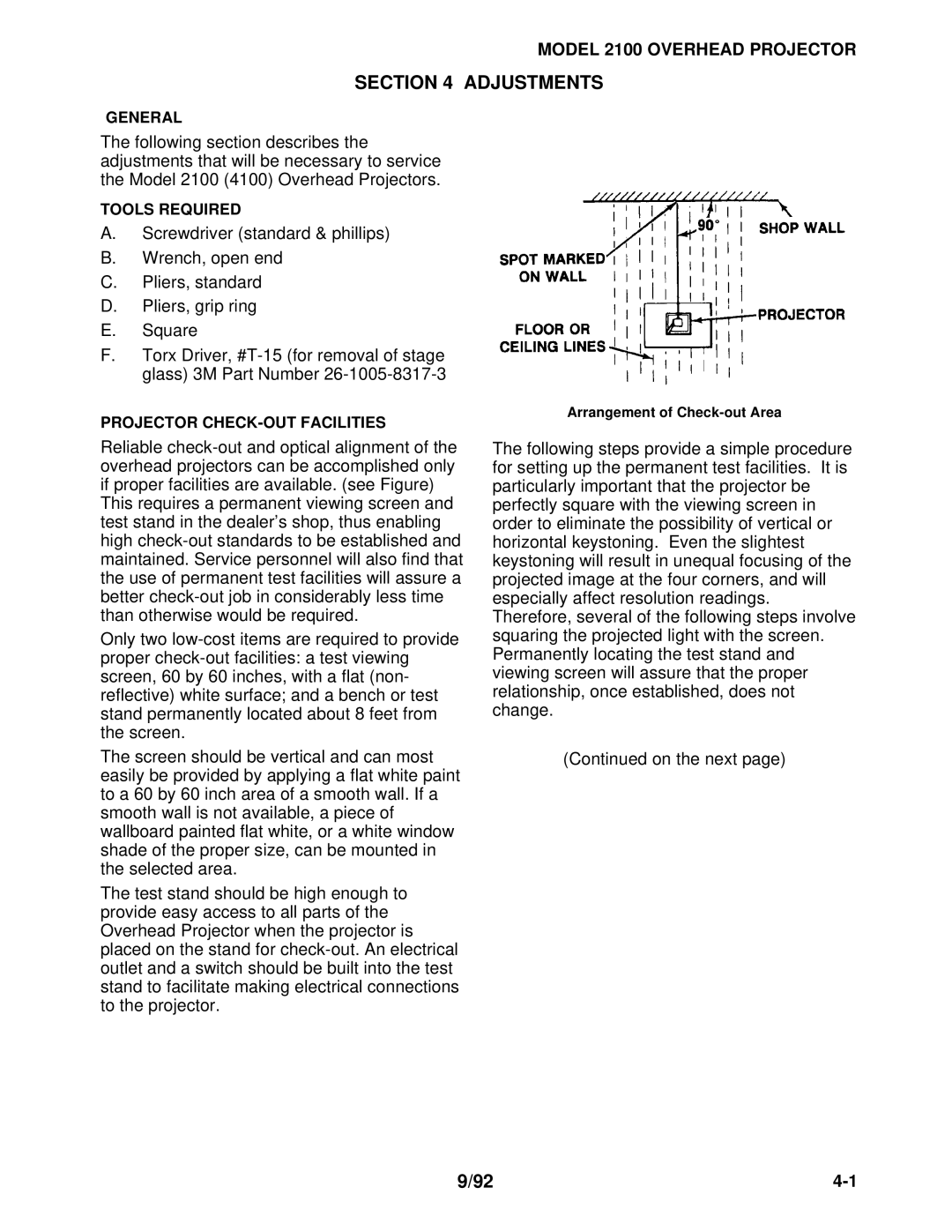

Arrangement of

The following steps provide a simple procedure for setting up the permanent test facilities. It is particularly important that the projector be perfectly square with the viewing screen in order to eliminate the possibility of vertical or horizontal keystoning. Even the slightest keystoning will result in unequal focusing of the projected image at the four corners, and will especially affect resolution readings. Therefore, several of the following steps involve squaring the projected light with the screen. Permanently locating the test stand and viewing screen will assure that the proper relationship, once established, does not change.

(Continued on the next page)

9/92 |