11.2 Connect ground braid to system ground according to standard practice.

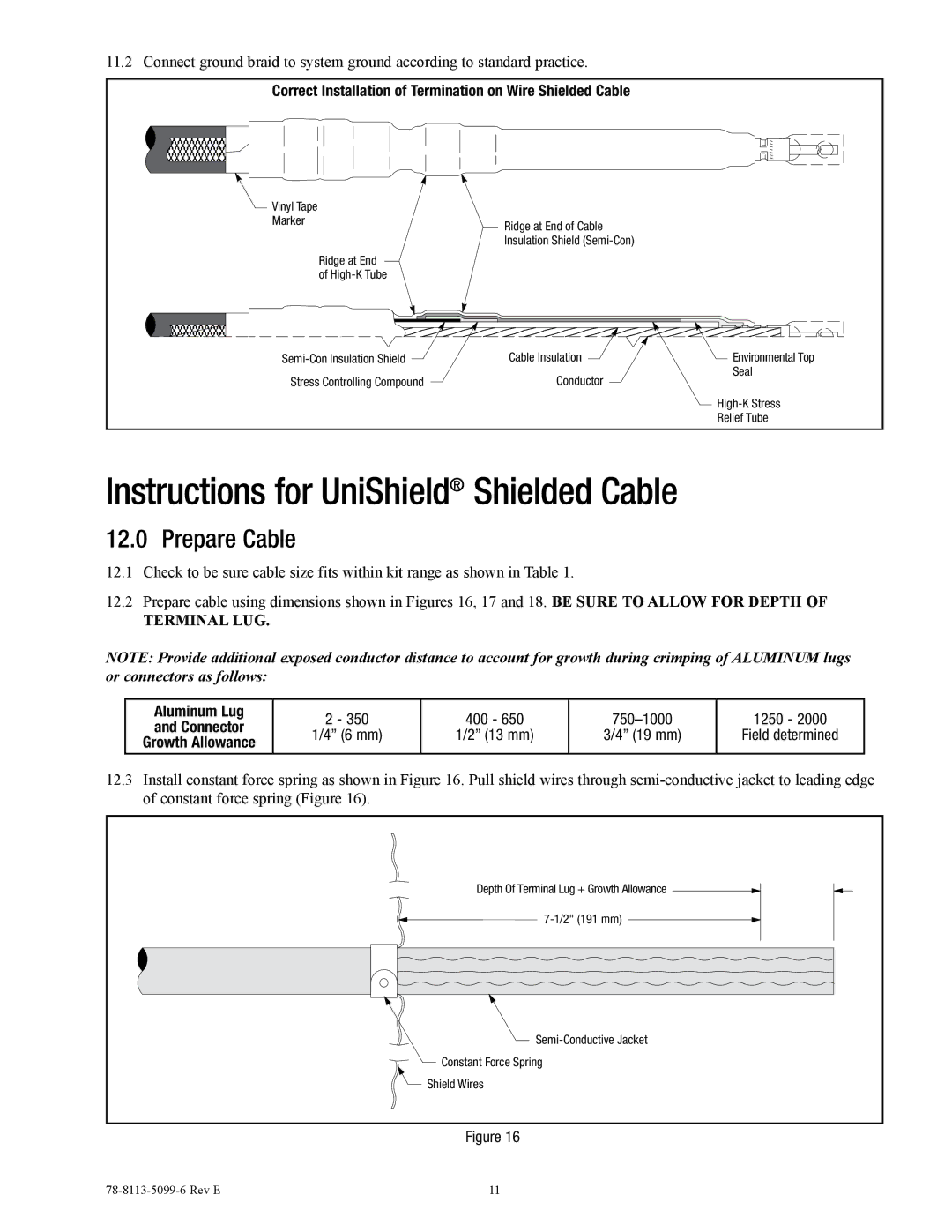

Correct Installation of Termination on Wire Shielded Cable |

| |

Vinyl Tape |

|

|

Marker | Ridge at End of Cable |

|

|

| |

| Insulation Shield |

|

Ridge at End |

|

|

of |

|

|

Cable Insulation | Environmental Top | |

Stress Controlling Compound | Conductor | Seal |

| ||

|

| |

|

| Relief Tube |

Instructions for UniShield® Shielded Cable

12.0Prepare Cable

12.1Check to be sure cable size fits within kit range as shown in Table 1.

12.2Prepare cable using dimensions shown in Figures 16, 17 and 18. BE SURE TO ALLOW FOR DEPTH OF

TERMINAL LUG.

NOTE: Provide additional exposed conductor distance to account for growth during crimping of ALUMINUM lugs or connectors as follows:

Aluminum Lug | 2 - 350 | 400 - 650 | 1250 - 2000 | ||

and Connector | |||||

1/4” (6 mm) | 1/2” (13 mm) | 3/4” (19 mm) | Field determined | ||

Growth Allowance | |||||

|

|

|

|

12.3Install constant force spring as shown in Figure 16. Pull shield wires through

Depth Of Terminal Lug + Growth Allowance |

Constant Force Spring |

Shield Wires |

Figure 16

11 |