Instructions for Wire Shielded Cable

7.0Prepare Cable

7.1Check to be sure cable size fits within kit range as shown in Table 1.

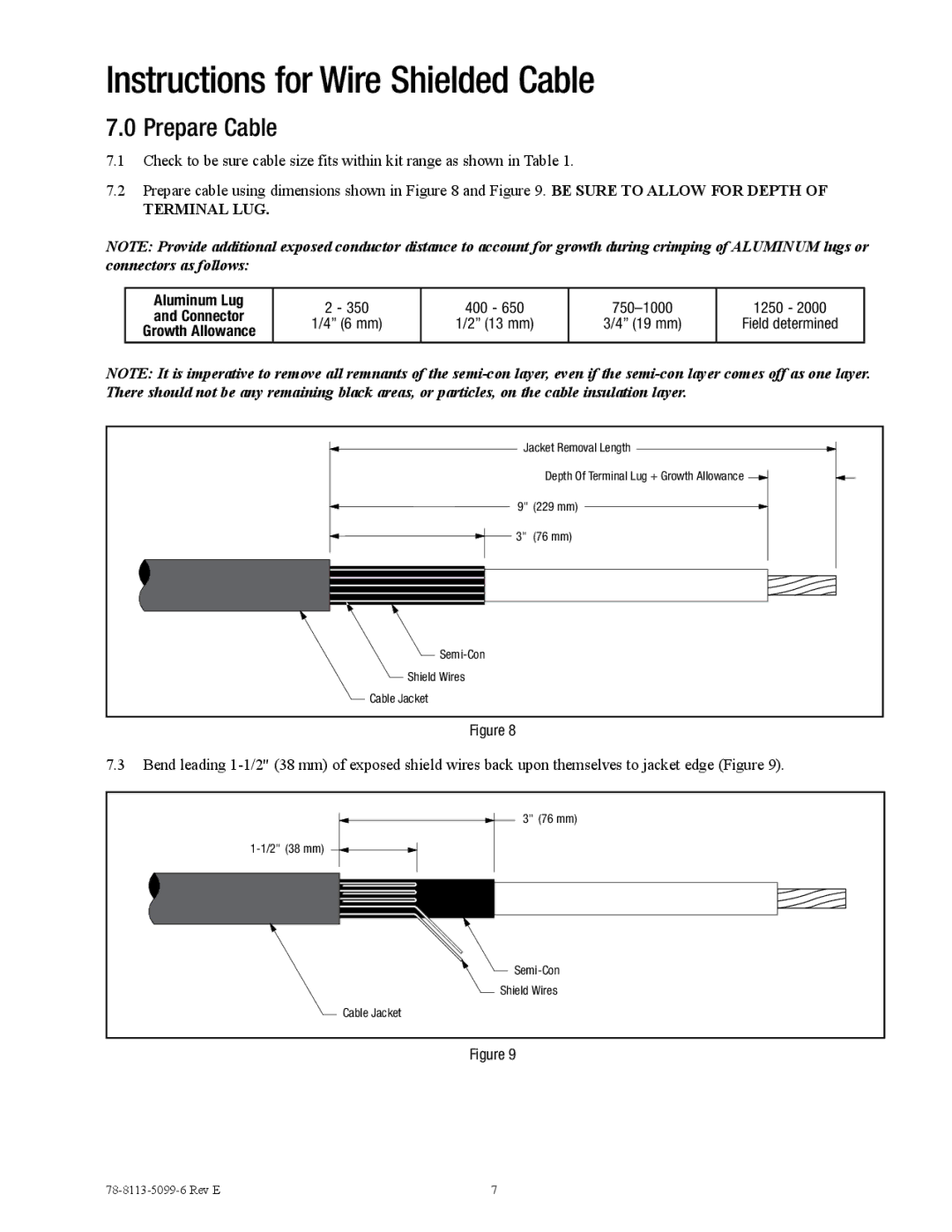

7.2Prepare cable using dimensions shown in Figure 8 and Figure 9. BE SURE TO ALLOW FOR DEPTH OF

TERMINAL LUG.

NOTE: Provide additional exposed conductor distance to account for growth during crimping of ALUMINUM lugs or connectors as follows:

Aluminum Lug | 2 - 350 | 400 - 650 | 1250 - 2000 | ||

and Connector | |||||

1/4” (6 mm) | 1/2” (13 mm) | 3/4” (19 mm) | Field determined | ||

Growth Allowance | |||||

|

|

|

| ||

|

|

|

|

|

NOTE: It is imperative to remove all remnants of the

Jacket Removal Length |

Depth Of Terminal Lug + Growth Allowance |

9" (229 mm) |

3" (76 mm) |

Shield Wires |

Cable Jacket |

Figure 8

7.3Bend leading

3" (76 mm) |

Shield Wires |

Cable Jacket |

Figure 9

7 |