6.0Connector Reusability

6.1Should it become necessary to separate the connector

and fiber, e.g. to reset the fiber protrusion, the activation cap within the connector can be deactivated. This is accomplished by first removing the connector from the port on the protrusion setting tool. Place the connector atop the deactivation station on the tool base, with the activation cap face up, and press firmly downward. This action releases the gripping mechanism within the connector. Limit the number of times a given connector is reused to one. A connector with its cap pushed down without a fiber inside, or with a fiber only partially inserted, is not reusable.

6.2To correct large, deep imperfections on the fiber face, restart at step 2.0. Replace the lapping film disc for each

6.3To correct small, shallow imperfections, such as small chips, reinsert the connector in the protrusion setter. Hold the fiber with your fingers and create a bow in the fiber. The bow length should be approximately as shown in Step 4.3 for 900 µm, and approximately as shown in Step 4.4 for 250 µm. Hold the fiber bow and begin completing Steps 4.5 through 5.8. Use a new piece of lapping film per Step 5.1.

7.0Troubleshooting

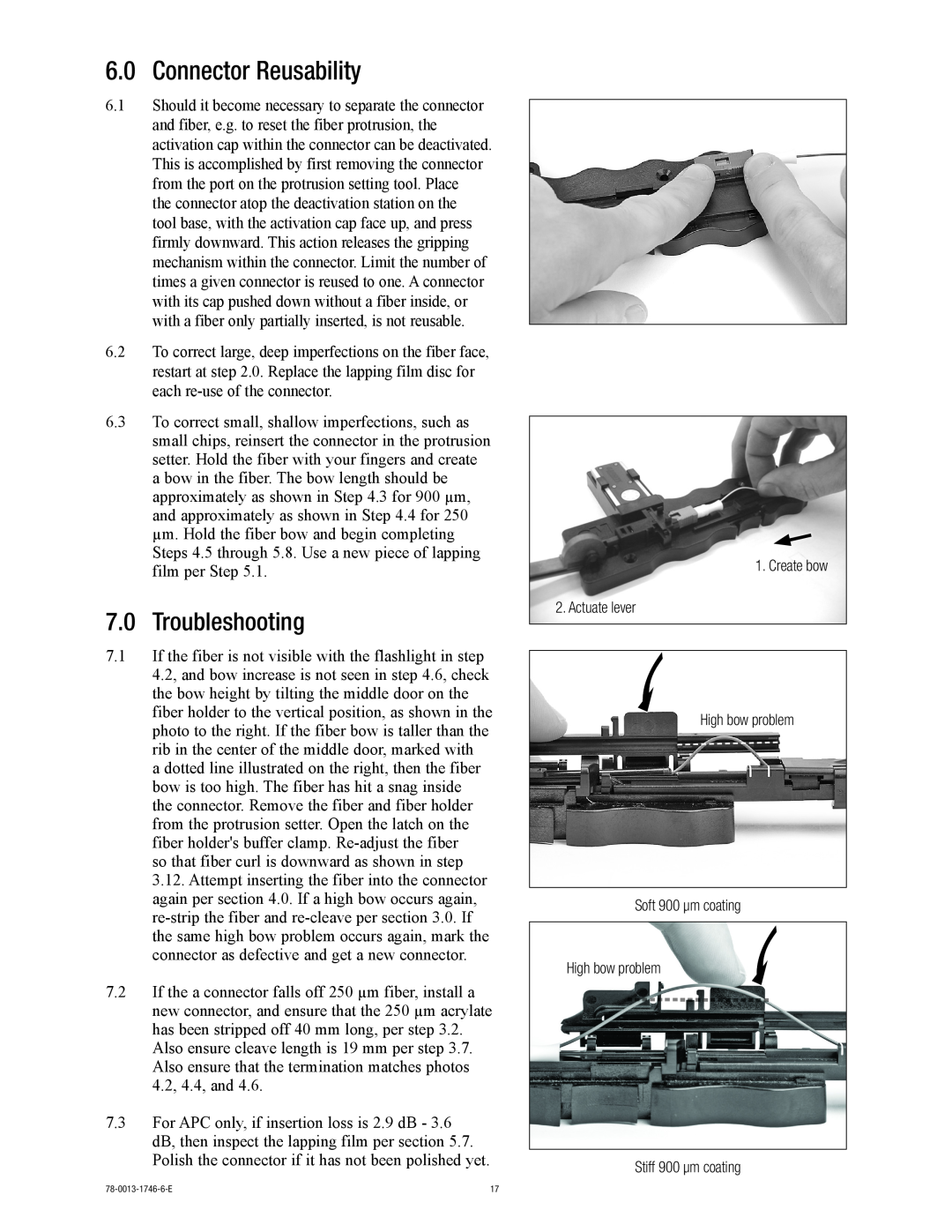

7.1If the fiber is not visible with the flashlight in step

4.2, and bow increase is not seen in step 4.6, check the bow height by tilting the middle door on the fiber holder to the vertical position, as shown in the photo to the right. If the fiber bow is taller than the rib in the center of the middle door, marked with a dotted line illustrated on the right, then the fiber bow is too high. The fiber has hit a snag inside the connector. Remove the fiber and fiber holder from the protrusion setter. Open the latch on the fiber holder's buffer clamp.

so that fiber curl is downward as shown in step

3.12. Attempt inserting the fiber into the connector again per section 4.0. If a high bow occurs again,

7.2If the a connector falls off 250 µm fiber, install a new connector, and ensure that the 250 µm acrylate has been stripped off 40 mm long, per step 3.2. Also ensure cleave length is 19 mm per step 3.7. Also ensure that the termination matches photos 4.2, 4.4, and 4.6.

7.3For APC only, if insertion loss is 2.9 dB - 3.6 dB, then inspect the lapping film per section 5.7. Polish the connector if it has not been polished yet.

1. Create bow

2. Actuate lever

High bow problem

Soft 900 µm coating

High bow problem

Stiff 900 µm coating

17 |