3.3For 900 µm, determine if the fiber is tight or semi- tight buffer. If the 900 µm slides easily from the fiber, it is

3.4For

3.5Test the stripped fiber for weak points by using your finger to slowly flick the fiber in multiple directions. Watch for the fiber to spring back to the straight position. If the fiber breaks, properly dispose of the

3.6Thoroughly clean the stripped fiber with a

Note: Carefully follow safety, health and environmental information given on the product label or the Material Safety Data Sheet for the isopropyl alcohol or cleaning fluid.

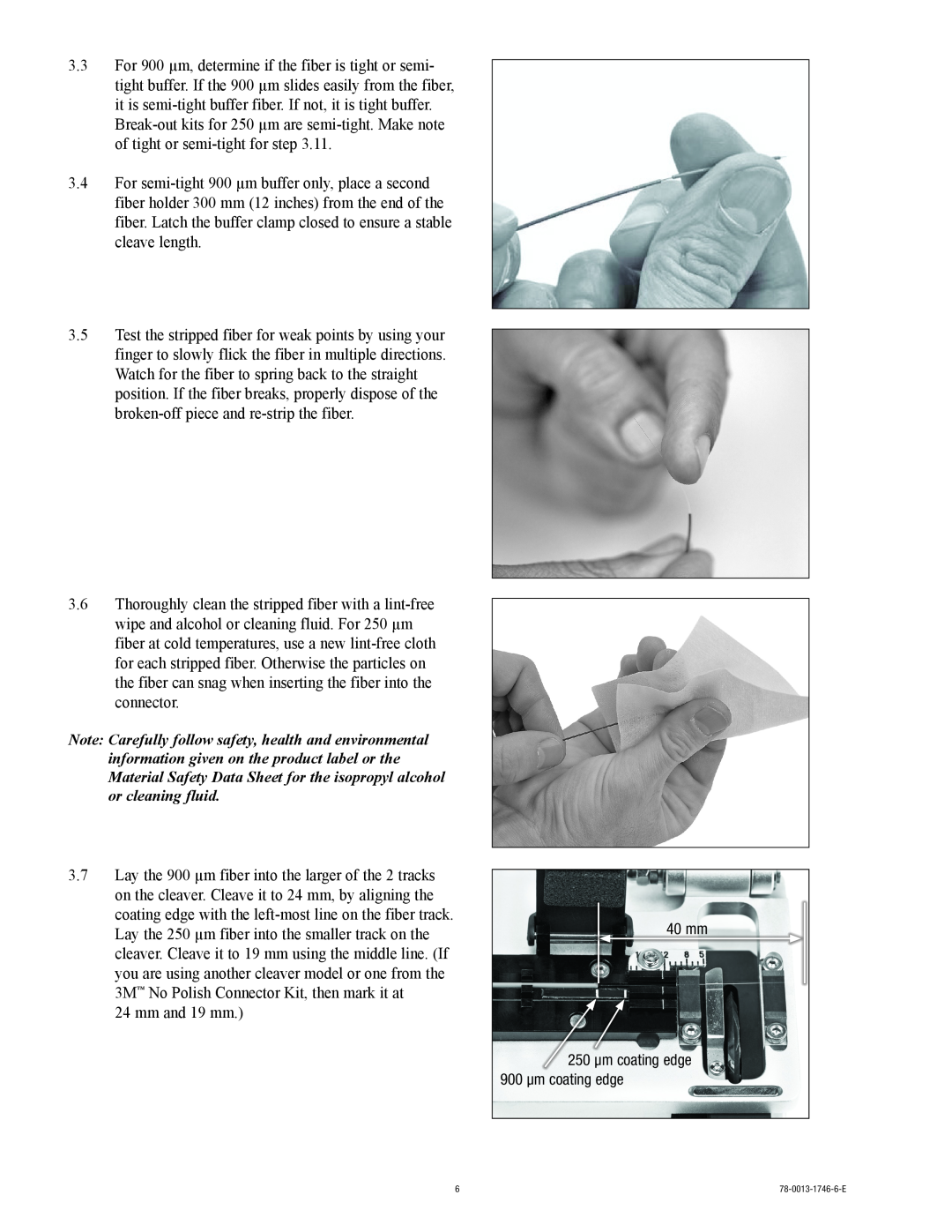

3.7Lay the 900 µm fiber into the larger of the 2 tracks on the cleaver. Cleave it to 24 mm, by aligning the coating edge with the

24 mm and 19 mm.)

40 mm

250 µm coating edge

900 µm coating edge

6 |