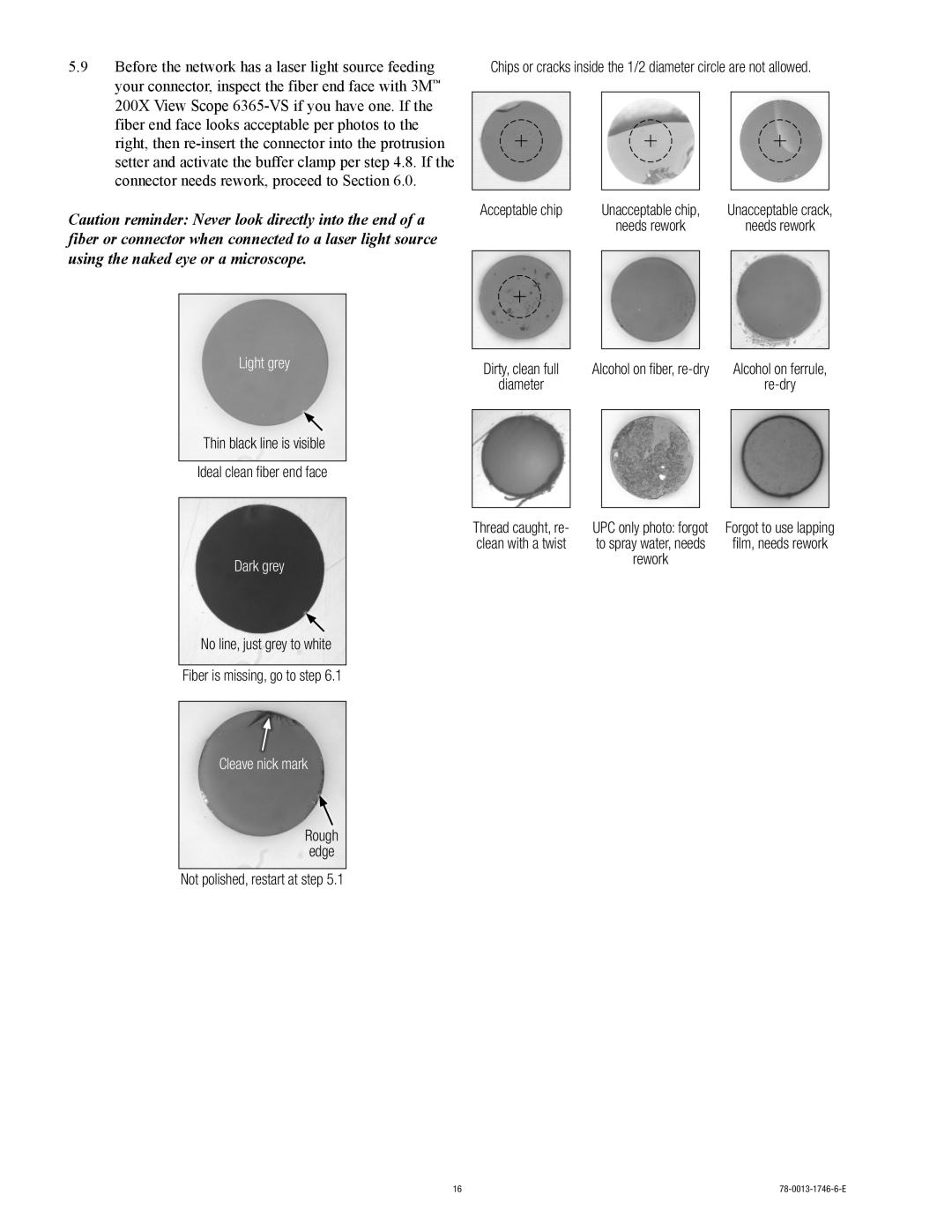

5.9Before the network has a laser light source feeding your connector, inspect the fiber end face with 3M™ 200X View Scope

Caution reminder: Never look directly into the end of a fiber or connector when connected to a laser light source using the naked eye or a microscope.

Light grey

Thin black line is visible

Ideal clean fiber end face

Chips or cracks inside the 1/2 diameter circle are not allowed.

Acceptable chip |

| Unacceptable chip, | Unacceptable crack, | ||||||

|

|

|

|

| needs rework |

| needs rework | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dirty, clean full | Alcohol on fiber, | Alcohol on ferrule, | ||

diameter |

|

|

| |

|

|

|

|

|

|

|

|

|

|

Dark grey

No line, just grey to white

Fiber is missing, go to step 6.1

Thread caught, re- | UPC only photo: forgot | Forgot to use lapping |

clean with a twist | to spray water, needs | film, needs rework |

| rework |

|

Cleave nick mark

Rough

edge

Not polished, restart at step 5.1

16 |