BFC - 80, BFC -100 specifications

A.O. Smith is a renowned name in the water heater industry, and its BFC series, which includes the BFC-100 and BFC-80 models, exemplifies their commitment to innovation and efficiency. These units are designed to meet the demanding needs of both residential and commercial applications, providing reliable hot water solutions.The A.O. Smith BFC-100 and BFC-80 are distinguished by their high capacity and robust design. The BFC-100 model boasts a capacity of 100 gallons, while the BFC-80 is ideal for those requiring 80 gallons. This makes them suitable for larger households or commercial establishments where hot water demand can be significant.

One of the primary features of these models is their advanced heating technology. Both units utilize a high-efficiency burner that ensures rapid heating and minimal energy consumption. This means users benefit from shorter wait times for hot water, reducing overall energy costs. The BFC series is also equipped with a special flame retention head that enhances combustion efficiency and prolongs the lifespan of the unit.

In terms of construction, the BFC-100 and BFC-80 models are built with high-quality materials that enhance durability and resistance to corrosion. The tanks are insulated with high-density foam, which improves energy retention and helps maintain water temperature for longer periods. This is crucial for conserving energy and minimizing heating costs.

Safety is a top priority for A.O. Smith, and the BFC series reflects this commitment. Each unit comes with a range of safety features, including a temperature and pressure relief valve that prevents overheating and excessive pressure buildup. Additionally, they are designed to meet strict industry standards, ensuring peace of mind for users.

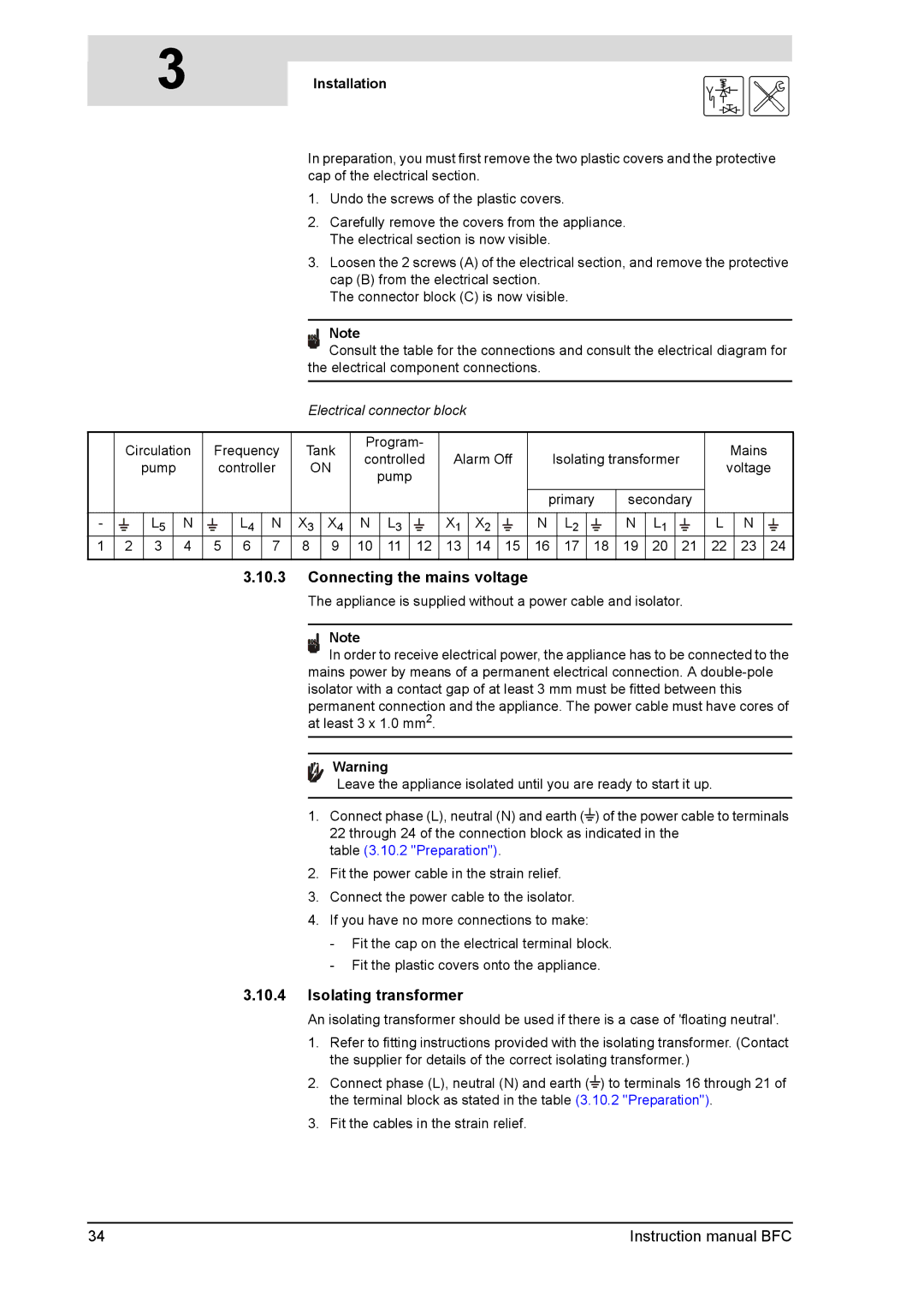

Installation of both models is straightforward, with flexible venting options that accommodate various building layouts. Whether you are upgrading an existing water heating system or installing a new one, the BFC series is designed to integrate seamlessly.

In summary, the A.O. Smith BFC-100 and BFC-80 are excellent options for those seeking reliable, efficient, and durable water heating solutions. With their impressive capacity, advanced heating technology, robust construction, and safety features, these models stand out in the market and are sure to meet the hot water needs of any household or commercial space. Whether for residential use or in a business setting, A.O. Smith’s BFC series represents quality and innovation in hot water heating.