diator hose is hot). Adjust engine RPM to the value specified by the vehicle manufac- turer for timing purposes. If no value is given, set the engine to curb idle.

4.Aim the timing light at the timing marks on the engine and pull the trigger switch.

5.With the trigger switch pulled, and while observing the timing marks, rotate the dis- tributor slowly clockwise or counterclock- wise as necessary to bring the timing into factory specification. On most engines, a change in timing will change engine RPM. If this happens, reset the engine RPM as indicated in Step 3 above and repeat Steps 4 and 5 until timing and RPM are within factory specifications.

6.Shut off the engine. Tighten the distributor hold down bolt securely.

7.Start the engine and recheck the timing. If it drifted during the bolt tightening process, readjust it as necessary.

8.Shut off the engine. Disconnect the timing light leads in the reverse order from which they were connected.

9.Reconnect any disconnected vacuum hoses or electrical connectors which were discon- nected as part of the engine’s preparation for timing. Reset the engine’s idle speed if necessary.

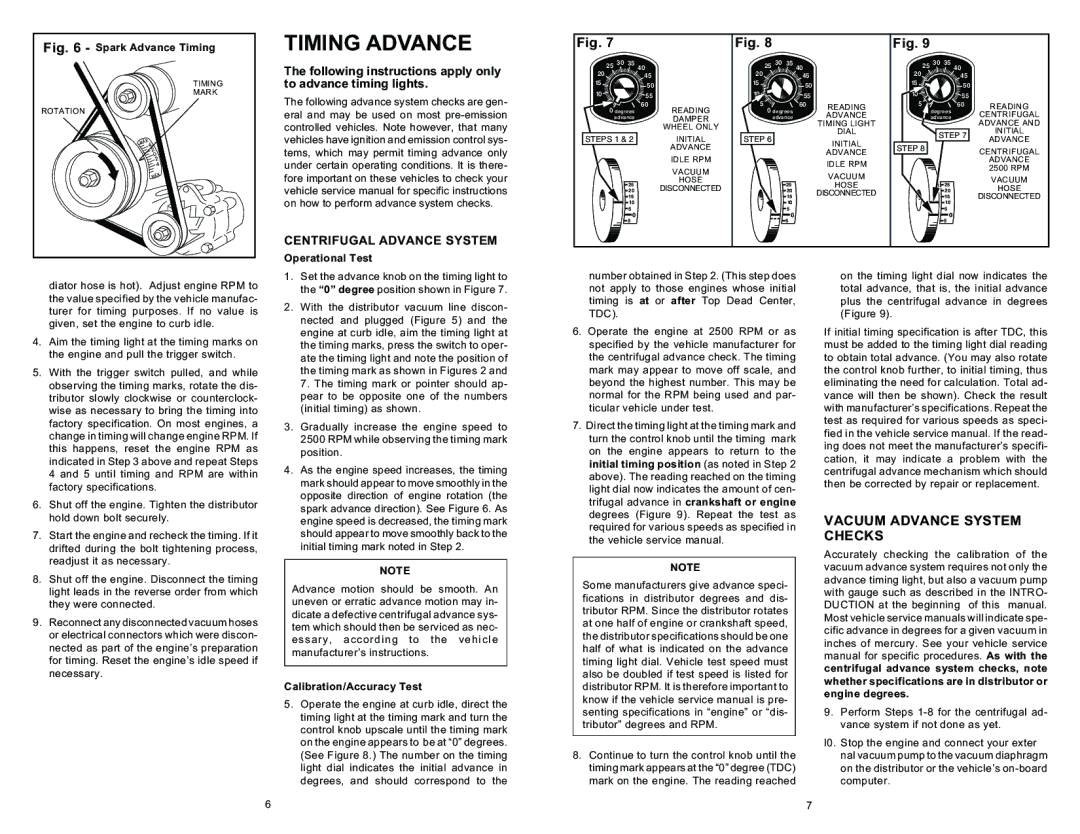

1.Set the advance knob on the timing light to the “0” degree position shown in Figure 7.

2.With the distributor vacuum line discon- nected and plugged (Figure 5) and the engine at curb idle, aim the timing light at the timing marks, press the switch to oper- ate the timing light and note the position of the timing mark as shown in Figures 2 and 7. The timing mark or pointer should ap- pear to be opposite one of the numbers (initial timing) as shown.

3.Gradually increase the engine speed to 2500 RPM while observing the timing mark position.

4.As the engine speed increases, the timing mark should appear to move smoothly in the opposite direction of engine rotation (the spark advance direction). See Figure 6. As engine speed is decreased, the timing mark should appear to move smoothly back to the initial timing mark noted in Step 2.

NOTE

Advance motion should be smooth. An uneven or erratic advance motion may in- dicate a defective centrifugal advance sys- tem which should then be serviced as nec- essary, according to the vehicle manufacturer’s instructions.

Calibration/Accuracy Test

5.Operate the engine at curb idle, direct the timing light at the timing mark and turn the control knob upscale until the timing mark on the engine appears to be at “0” degrees. (See Figure 8.) The number on the timing light dial indicates the initial advance in degrees, and should correspond to the

number obtained in Step 2. (This step does not apply to those engines whose initial timing is at or after Top Dead Center, TDC).

6.Operate the engine at 2500 RPM or as specified by the vehicle manufacturer for the centrifugal advance check. The timing mark may appear to move off scale, and beyond the highest number. This may be normal for the RPM being used and par- ticular vehicle under test.

7.Direct the timing light at the timing mark and turn the control knob until the timing mark on the engine appears to return to the initial timing position (as noted in Step 2 above). The reading reached on the timing light dial now indicates the amount of cen- trifugal advance in crankshaft or engine degrees (Figure 9). Repeat the test as required for various speeds as specified in the vehicle service manual.

NOTE

Some manufacturers give advance speci- fications in distributor degrees and dis- tributor RPM. Since the distributor rotates at one half of engine or crankshaft speed, the distributor specifications should be one half of what is indicated on the advance timing light dial. Vehicle test speed must also be doubled if test speed is listed for distributor RPM. It is therefore important to know if the vehicle service manual is pre- senting specifications in “engine” or “dis- tributor” degrees and RPM.

8.Continue to turn the control knob until the timing mark appears at the “0” degree (TDC) mark on the engine. The reading reached

on the timing light dial now indicates the total advance, that is, the initial advance plus the centrifugal advance in degrees (Figure 9).

If initial timing specification is after TDC, this must be added to the timing light dial reading to obtain total advance. (You may also rotate the control knob further, to initial timing, thus eliminating the need for calculation. Total ad- vance will then be shown). Check the result with manufacturer’s specifications. Repeat the test as required for various speeds as speci- fied in the vehicle service manual. If the read- ing does not meet the manufacturer’s specifi- cation, it may indicate a problem with the centrifugal advance mechanism which should then be corrected by repair or replacement.

VACUUM ADVANCE SYSTEM CHECKS

Accurately checking the calibration of the vacuum advance system requires not only the advance timing light, but also a vacuum pump with gauge such as described in the INTRO- DUCTION at the beginning of this manual. Most vehicle service manuals will indicate spe- cific advance in degrees for a given vacuum in inches of mercury. See your vehicle service manual for specific procedures. As with the centrifugal advance system checks, note whether specifications are in distributor or engine degrees.

9.Perform Steps 1-8 for the centrifugal ad- vance system if not done as yet.

l0. Stop the engine and connect your exter nal vacuum pump to the vacuum diaphragm on the distributor or the vehicle’s on-board computer.