Use, Maintenance, and Care of the Devices

Connections

Connections

Good connections require a skilled operator. The most common cause of measurement error is bad connections. The following procedures illustrate how to make good connections.

How to Make a Connection

Preliminary Connection

1.Ground yourself and all devices. Wear a grounded wrist strap and work on a grounded, conductive table mat. Refer to “Electrostatic Discharge” on page

2.Visually inspect the connectors. Refer to “Visual Inspection” on page

3.If necessary, clean the connectors. Refer to “Cleaning Connectors” on page

4.Use a connector gage to verify that all center conductors are within the observed pin depth values in Table

5.Carefully align the connectors. The male connector center pin must slip concentrically into the contact finger of the female connector.

6.Push the connectors straight together.

CAUTION Do not turn the device body. Only turn the connector nut. Damage to the center conductor can occur if the device body is twisted.

Do not twist or screw the connectors together. As the center conductors mate, there is usually a slight resistance.

7.The preliminary connection is tight enough when the mating plane surfaces make uniform, light contact. Do not overtighten this connection.

A connection in which the outer conductors make gentle contact at all points on both mating surfaces is sufficient. Very light finger pressure is enough to accomplish this.

8.Make sure the connectors are properly supported. Relieve any side pressure on the connection from long or heavy devices or cables.

Final Connection Using a Torque Wrench

1.Use a torque wrench to make a final connection. Table

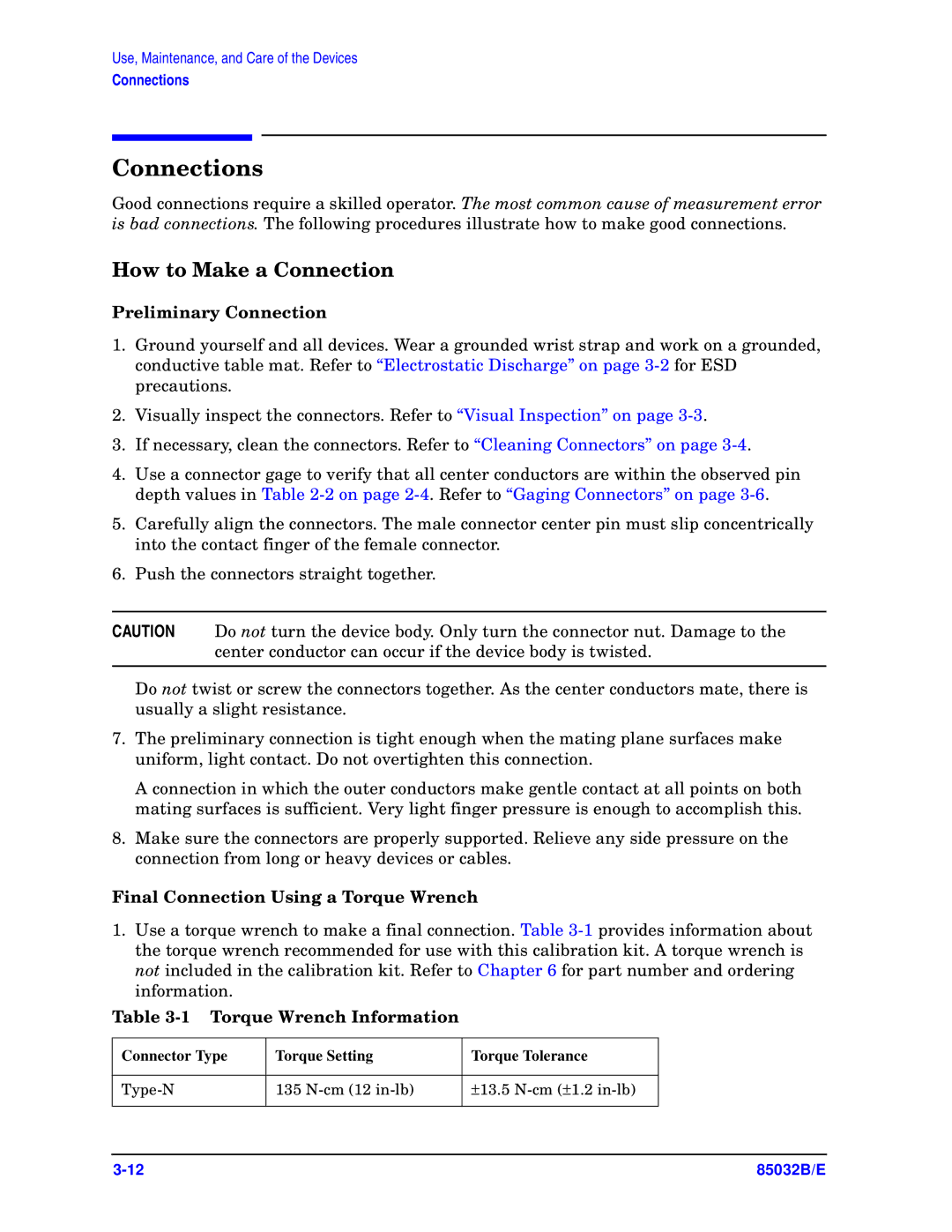

Table 3-1 Torque Wrench Information

Connector Type | Torque Setting | Torque Tolerance |

|

|

|

135 | ±13.5 | |

|

|

|

85032B/E |