OPERATING MANUAL

AGILENT 603xA FAMILY AUTORANGING SYSTEM DC POWER SUPPLIES

LIMITATION OF WARRANTY

WARRANTY

CERTIFICATION

EXCLUSIVE REMEDIES

Safety Summary

SAFETY SYMBOLS

Declaration Page

DECLARATION OF CONFORMITY

Herstellerbescheinigung

Acoustic Noise Statement

Manufacturer’s Declaration

Installation

Table Of Contents

General Information

Operating Instructions

Table Of Contents continued

100 VAC Input Power Option

Table Of Contents continued

Standard Commands for Programmable Instruments

Blank Front Panel Option

Programming the Agilent 603xA Power Supplies Using BASIC

Table Of Contents continued

Index

Introduction

General Information

Description

Accessories

Safety Considerations

Options

Option

Instrument and Manual Identification

GP-IB Compatibility

GP-IB Interconnection Cables and Connectors

Ordering Additional Manuals

Model

Related Documents

Specifications

Table 1-2. Supplemental Characteristics

Table 1-1. Performance Specifications

Agilent Technologies Model

6033A

6031A

6030A

6032A

6035A

18 General Information

Table 1-2. Supplemental Characteristics continued

Agilent Model

Figure 1-1. Output Characteristic Curve

6030A

6031A

20 General Information

Initial Inspection

Installation

Preparation For Use

Outline Diagram

Input Power Requirements

Figure 2-1. Outline Diagram Bench Operation

Power Connection

22 Installation

Figure 2-2. Power-Cord Plug Configurations

Line Voltage Option Conversion

f. Change line label

Figure 2-3. Line Voltage Conversion Components

26 Installation

Repackaging For Shipment

AC Line Impedance Check

Rear Panel Screw Sizes and Part Numbers

Agilent Models 6030A, 6031A, 6032A, 6035A

Agilent Model 6033A

28 Installation

Agilent Model 6038A

Figure 2-4. Part Number Location

Figure 3-1. Front-Panel Controls and Indicators

OPERATING INSTRUCTIONS

Introduction

Output Range For An Autoranging Power Supply

Controls and Indicators

Figure 3-2. Determining Operating Point

Table 3-1. Controls and Indicators

Controls/Indicators

Number

Figure 3-3. Overrange Operation

Controls/Indicators

Table 3-1. Controls and Indicators continued

Number

Description

Table 3-1. Controls and Indicators continued

Turn-On Checkout Procedure

Controls/Indicators

Number

Figure 3-4. Factory Settings, Mode Switch

Connecting the Load

Initial Setup and Interconnections

maximum length =

Table 3-2. Maximum Wire Lengths To Limit Voltage Drops

current x resistivity

Cross Section Area In mm2

Cross Section Area in mm2

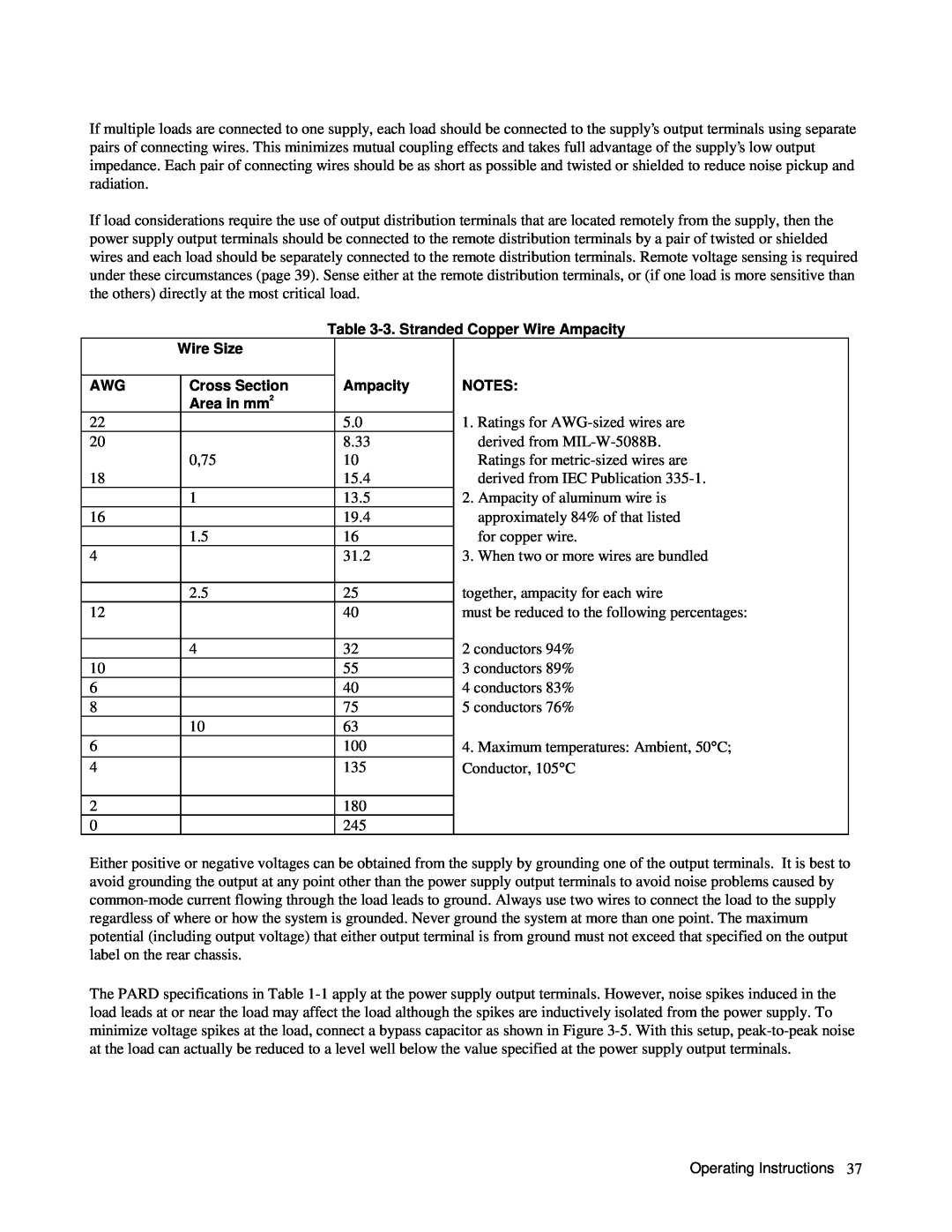

Table 3-3. Stranded Copper Wire Ampacity Wire Size

Ampacity

Figure 3-5. Connecting a Bypass Capacitor Overvoltage Protection OVP

Foldback Protection

Remote Voltage Sensing

2Rs +.5 1000

Mode Switches

Figure 3-6. Remote Voltage Sensing

Table 3-4. Mode Switches

Mode Switches

Figure 3-7. GP-IB Connector

Programming Mode

Protective Circuits

Monitor Signals

Constant Voltage Operation

Local Operation

Constant Current Operation

GP-IB Operation

Return to Local

Interface Functions

Multiline Message Control Functions. The Acceptor Handshake, Source Handshake, Listener, and Talker functions are implemented by the interface circuits of the power supply and the controller and require no action by the user. The LSN or TLK indicators turn on when the power supply is addressed to listen or talk. The talker function includes serial poll, see below

Table 3-5. Serial Poll Register

GP-IB Address Selection

INH-FLT or RLY LNK Operation

Power-On Service Request

Figure 3-8. GP-IB Address/PON SRQ Switches

Initial Conditions

Table 3-6. Initial Conditions

Programming Syntax

+ 1.23 E + 4 + 123. E +

Table 3-7 GP-IB Commands

Command

Range or **Response

To Query

Table 3-7 GP-IB Commands continued

Command

Range or **Response

Page

Table 3-7 GP-IB Commands continued

Command

Range or **Response

Page

Table 3-7 GP-IB Commands continued

Command

Range or **Response

Page

Table 3-7 GP-IB Commands continued

Command

Range or **Response

Page

Table 3-8. Format of Numbers Sent from Power Supply

VSET? and addressing the power supply to talk

VMAX

OUT OFF or OUT OUT ON or OUT

Hold is turned on and off using these codes HOLD OFF or HOLD

60 Operating Instructions

Table 3-9. Status Register

Bit Weight

Bit Position

Condition

62 Operating Instructions

SRQ?

Table 3-10. Status Register Errors Description

Error #

No Errors

Analog Programming

66 Operating Instructions

Figure 3-9. Resistance Programming of Output Voltage

Figure 3-10. Voltage Programming of Output Voltage

Multiple-Supply Operation

Figure 3-11. Optional Voltage Divide for Program Source

Figure 3-13. Voltage Programming of Output Current

Figure 3-12. Resistance Programming of Output Current

Auto-Parallel Operation

68 Operating Instructions

Series Operation

Figure 3-14. Auto-Parallel Operation

Figure 3-15. Series Operation

Fault Input FLT and Remote Inhibit INH Connections

Figure 3-18. FLT Example

Figure 3-16. FLT/INH Connections Figure 3-17. INH Example

Operating Instructions

Figure 3-19a. FLT and INH with Multiple Supplies

Figure 3-19b. Typical INH Setup

72 Operating Instructions

Figure 3-20. Timing Diagram Figure 3-21. FLT & INH Example

Using Appendix A

100 VAC Input Power Option

General Information Description

Scope of Appendix A

Section lll Manual Changes

Section ll Manual Changes

Agilent Model

Set a

100 VAC Input Power Option 100

Turn-On Check Out Procedure

Blank Front Panel Option

Introduction

Description

Agilent 6030A Agilent 6031A Agilent 6032A Agilent 6033A

Overvoltage Protection Setting

Table B-2. CC Check Command String

Agilent Model

String

ABOUT THIS APPENDIX

Standard Commands for Programmable Instruments SCPI

READER PATH

REFERENCES

INTRODUCTION

LANGUAGE SWITCHING

STAND-ALONE CONNECTIONS

Installation

LINKED CONNECTIONS

Figure C-1 Linked Connections

Addressing Over the Bus

Setting the Address

GP-IB Address

Type of Connection

COMMON Commands

LANGUAGE DICTIONARY

Subsystem Commands

Keywords

Figure C-3. Agilent Series 663xA Subsystem Tree Diagram

Figure C-2. Common Command Syntax Diagram

88 Standard Commands for Programmable Instruments SCPI

Bit Configuration of Standard Event Status Enable Register

Event Status Enable

Meaning and Type

Clear Status Device Status

IDN?

ESR?

0 to

Meaning and Type

Power-on Status Clear

OPC?

Description

Pending operations are complete when

0 or

0 or l

Meaning and Type

Description

Meaning and Type

Reset

Device State

Description

Service Request Enable

STB?

Bit Configuration of Status Byte Register

Meaning and Type

ABOR

TST?

Meaning and Type

Trigger

CURRLEV

Current Subsystem

CURRPROTSTAT

0 or OFF

Measure Subsystem

Initiate Subsystem

Output Subsystem

For INITCONT 0 or OFF 1 or ON

I or ON

0 or OFF

0 or

CRD NORMal or REVerse

Bit Configuration of Operation Registers

Status Subsystem

Status Operation Registers

0 to

STATUS PRESET

NTR/PTR Commands

Bit Configuration of Questionable Registers

0 to

STATQUESCOND?

NTR/PTR Commands

STATQUESENAB

0 to

SYSTLANG

SYSTERR?

0 to

Syntax is the same, regardless of the present language

Voltage Subsystem

Trigger Subsystem

TRIGSOUR

VOLTPROTAMPL?

STATUS REPORTING

Table C-5. Bit Configuration of Status Reister Groups Meaning

Signal

Status Byte and Service Request Enable Registers

Operation Status Group

Table C-2. STATQUES Commands

Figure C-4. Power Supply Status Structure

Command

Register

Enable

Signal

Table C-4. STATOPER Commands

Command

Enables all error conditions into the ESB summary bit

Service Request Enable Register

Program Command

Clear Command

Output Queue

SCPI ERROR MESSAGES

Enables all bits to generate seruice requests

Excludes the MAV bit from gerlerating a service request

Table C-5. Summary of Error Messages

Error Number

Error String Description/Explanation/Examples

Table C-5. Summary of Error Messages continued

Error Number

Error String Description/Explanation/Examples

SCPI COMMAND SUMMARY

Command

Command Summary continued Subsystem Commands

Command

Command

Table C-6. Comparison of ARPS and SCPI Commands

ARPS/SCPI Commands

ARPS Command

Equivalent SCPI Command

I/O Path Names

Programming the Agilent 603xA Power Supplies Using Basic

Initialization

Voltage and Current Programming

Voltage and Current Readback

120 130 DEF FNSettledOPTIONAL Band, Rdgs.Timelimit

Power Supply Status

Output Inhibit / Enable

Present Status

FOLD

Accumulated Status

Serial Poll

Fault and Mask Registers

Page

Service Request

Delay Time

Programming Error Detection

Explanation

124 Programming the Agilent 603xA Power Supplies Using Basic

Fault Indicator FLT and Inhibit INH

Protection Functions

Overvoltage

Foldback

Hold Mode

Advanced Topics

Machines States

Explanation

Programming the Agilent 603xA Power Supplies Using Basic

Index

Index

Index

CC bit

130 Index

Index

Index

output enable

OPC bit

132 Index

United States

Agilent Sales and Support Office

Canada

Europe

Manual Updates