SERVICING THE FURNACE

ELECTRICAL SHOCK, FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in dangerous operation, serious injury, death or property damage.

Improper servicing could result in dangerous operation, serious injury, death or property damage.

•Before servicing, disconnect all electrical power to furnace.

•Wehn servicing controls, label all wires prior to disconnecting. Reconnect wires correctly.

•Verify proper operation after servicing.

The ability to properly perform maintenance on this equipment requires certain mechanical skills and tools. If you are at all uncertain, contact your dealer for qualified maintenance and service since improper service could lead to furnace shutdown or a hazardous condition which could lead to an unsafe condition and bodily harm.

Combustion Component Check:

The heat exchanger, gas burners and venting system must be checked each year, prior to the heating season, by a qualified dealer/serviceman.

The following procedures should be performed:

1.Remove the burner/manifold assembly from the furnace, follow the instructions found on this page.

2.Place the burner/manifold assembly on a flat work area and vacuum the burners. It might be necessary to use a soft bristly brush to remove dirt and then vacuum.

3.Disconnect wiring to combustion blower.

4.Disconnect wiring to pressure switches, and remove pressure switches.

5.Remove the burner opening inlet plate and the flue collector box with the combustion blower attached. This will expose both the burner and flue openings of the primary heat exchangers.

6.Vacuum the length of each heat exchanger tube using a straight attachment into the burner openings and the flue openings.

7.Replace the flue collector box, burner opening inlet plate, and burner/manifold assembly. Insure that all gaskets are properly positioned and that no leaks exist.

8.Reattach all wiring and piping as per the wiring diagram and installation instructions.

9.Turn on utilities and check for leaks using soapy water and a brush.

10.A visual check of the main burner should be made at the beginning of each heating season.

11.Check the input rate and adjust if necessary.

12.Perform a safety check of the limit control and pressure switch.

13.Check the air filter, clean and/or replace as necessary.

14.Replace the appropriate access panels or door.

Never use an open flame when testing for gas leaks! Use of an open flame could lead to a fire or explosion!

Many soaps used for leak testing are corrosive to certain metals. Piping must be rinsed thoroughly with clean water after leak check has been completed.

Manifold (or Burner/Manifold) Removal/Replacement:

1.Make sure that all utilities (gas and electricity) are turned off upstream of the furnace.

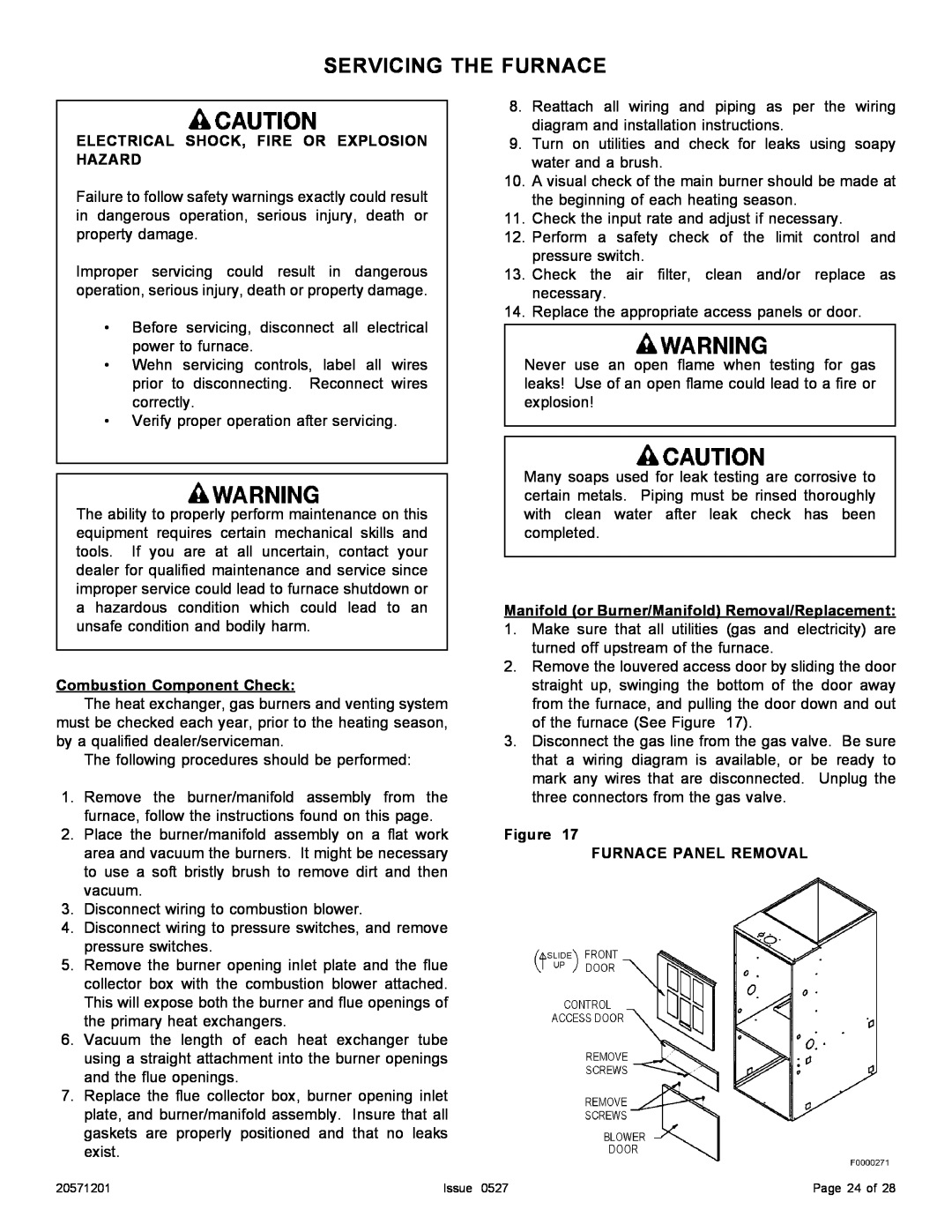

2.Remove the louvered access door by sliding the door straight up, swinging the bottom of the door away from the furnace, and pulling the door down and out of the furnace (See Figure 17).

3.Disconnect the gas line from the gas valve. Be sure that a wiring diagram is available, or be ready to mark any wires that are disconnected. Unplug the three connectors from the gas valve.

Figure 17

FURNACE PANEL REMOVAL

20571201 | Issue 0527 | Page 24 of 28 |