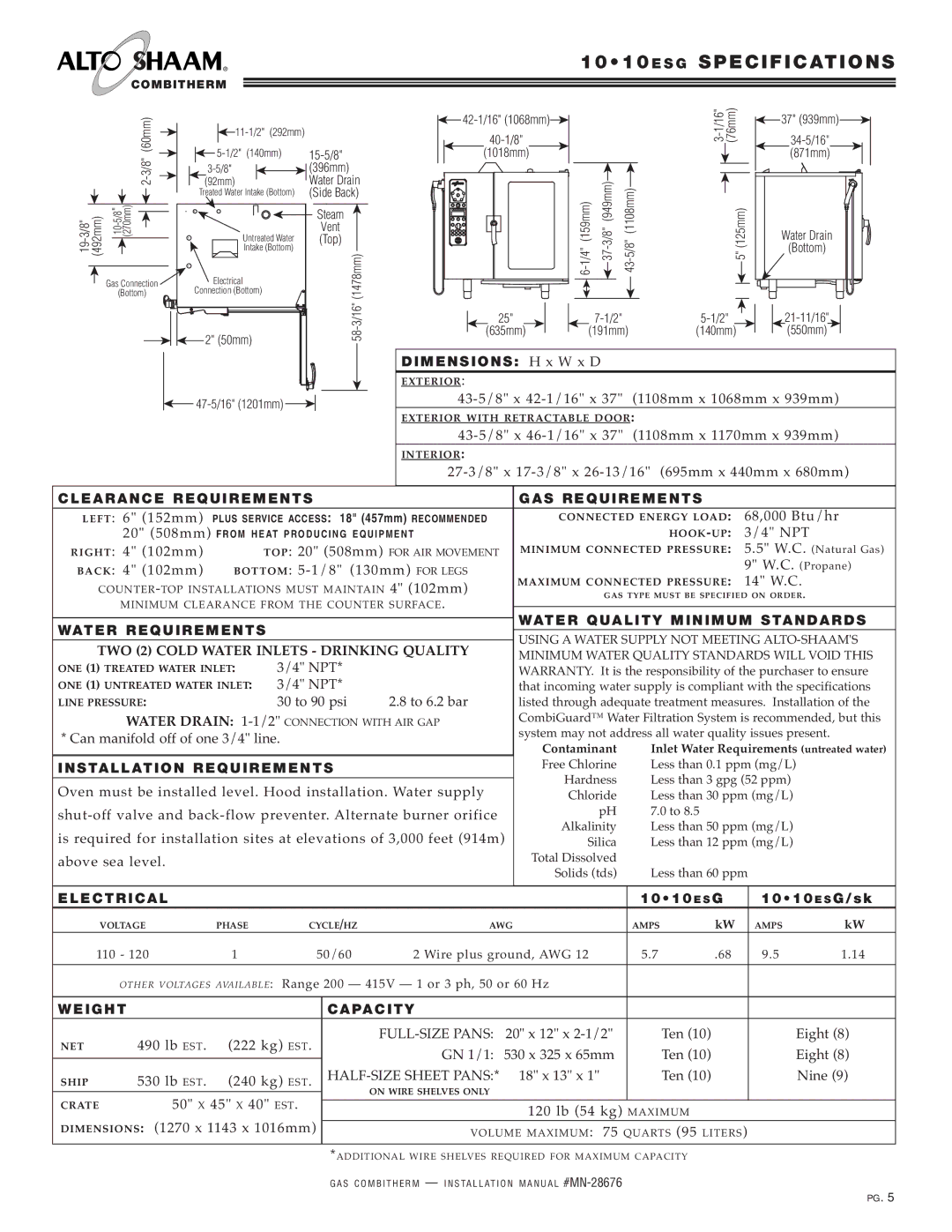

6.10ESG, 10.20ESG, 10.10ESG specifications

Alto-Shaam, a leader in commercial kitchen equipment, has revolutionized the foodservice industry with its innovative products, particularly the 10.10ESG, 10.20ESG, and 6.10ESG models. These versatile cook and hold ovens are designed to enhance food quality while improving operational efficiency.The 10.10ESG is an impressive model that accommodates various cooking needs, offering a generous capacity combined with precise temperature control. With the ability to operate at a maximum temperature of 325°F, it allows for consistent cooking results, ensuring that food is held at the desired temperature without drying out. This model features advanced digital controls that allow operators to set and monitor cooking cycles with ease, ensuring precise results every time.

Moving on to the 10.20ESG, this model takes cooking versatility to a new level. With its dual convection and steam cooking options, it is ideal for establishments requiring high-volume cooking. This model boasts enhanced humidity control, which helps maintain food moisture, texture, and overall quality. The 10.20ESG allows operators to cook a variety of foods—from meats to pastries—with remarkable efficiency and reliability. Its energy-efficient design not only saves on operational costs but elevates the quality and consistency of the food prepared.

The 6.10ESG is the compact version, specifically designed to cater to smaller operations without compromising on technology or performance. Despite its smaller size, this model is equipped with the same advanced digital controls and cooking technologies as the larger versions. It features a powerful heating system that ensures even cooking and browning. Ideal for restaurants, cafes, and catering services that require flexibility, the 6.10ESG shines in busy kitchen environments where space is at a premium.

Collectively, these models share several key features: the patented Halo Heat technology, which provides gentle, even cooking without direct heat, eliminates hot spots, and holds food at optimal serving temperatures. Each model also prioritizes energy efficiency, contributing to lower utility costs while maintaining exceptional performance and food quality.

In summary, Alto-Shaam’s 10.10ESG, 10.20ESG, and 6.10ESG represent the pinnacle of cooking technology designed for modern foodservice operations. Their robust features and innovative cooking methods allow for increased efficiency, improved food quality, and a significant reduction in labor costs, making them indispensable tools in any commercial kitchen.