3.Electrical Connections

NOTE: A wiring diagram is included with each dryer and is affixed to the rear upper right guard/ panel of the dryer.

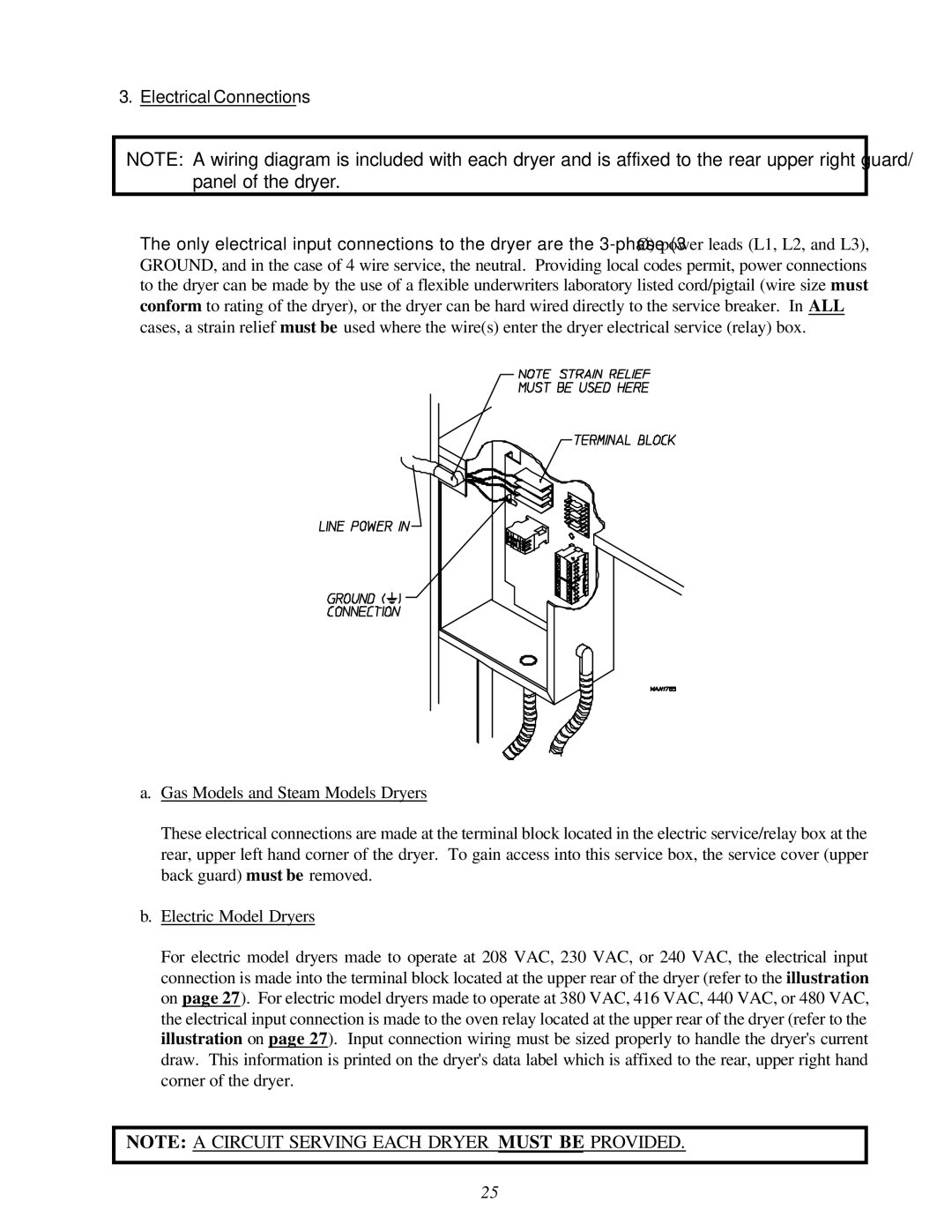

The only electrical input connections to the dryer are the

a.Gas Models and Steam Models Dryers

These electrical connections are made at the terminal block located in the electric service/relay box at the rear, upper left hand corner of the dryer. To gain access into this service box, the service cover (upper back guard) must be removed.

b.Electric Model Dryers

For electric model dryers made to operate at 208 VAC, 230 VAC, or 240 VAC, the electrical input connection is made into the terminal block located at the upper rear of the dryer (refer to the illustration on page 27). For electric model dryers made to operate at 380 VAC, 416 VAC, 440 VAC, or 480 VAC, the electrical input connection is made to the oven relay located at the upper rear of the dryer (refer to the illustration on page 27). Input connection wiring must be sized properly to handle the dryer's current draw. This information is printed on the dryer's data label which is affixed to the rear, upper right hand corner of the dryer.

NOTE: A CIRCUIT SERVING EACH DRYER MUST BE PROVIDED.

25