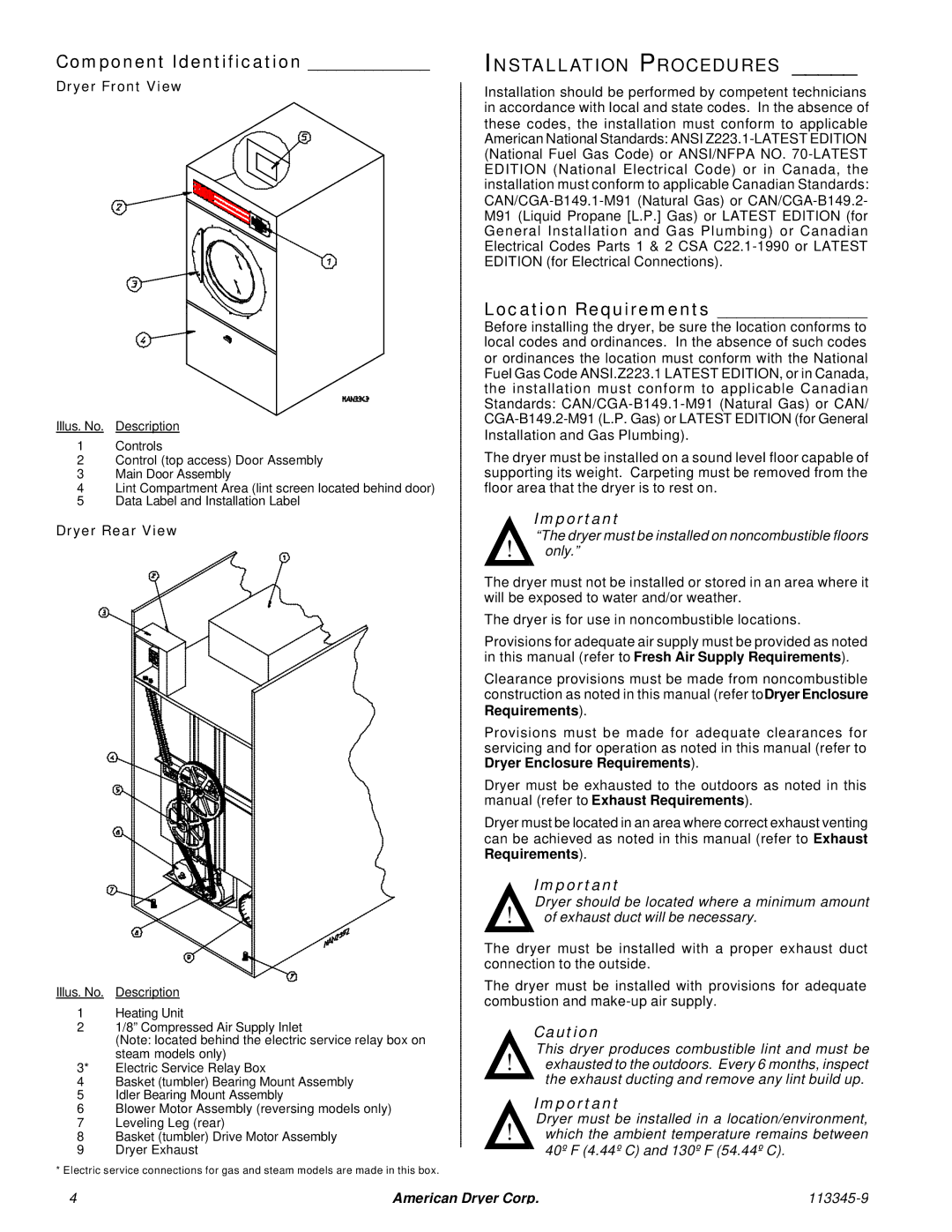

Component Identification _____________

Dryer Front View

Illus. No. Description

1Controls

2Control (top access) Door Assembly

3Main Door Assembly

4Lint Compartment Area (lint screen located behind door)

5Data Label and Installation Label

Dryer Rear View

Illus. No. Description

1Heating Unit

21/8” Compressed Air Supply Inlet

(Note: located behind the electric service relay box on steam models only)

3* Electric Service Relay Box

4Basket (tumbler) Bearing Mount Assembly

5Idler Bearing Mount Assembly

6Blower Motor Assembly (reversing models only)

7Leveling Leg (rear)

8Basket (tumbler) Drive Motor Assembly

9Dryer Exhaust

*Electric service connections for gas and steam models are made in this box.

INSTALLATION PROCEDURES _____

Installation should be performed by competent technicians in accordance with local and state codes. In the absence of these codes, the installation must conform to applicable American National Standards: ANSI

Location Requirements ________________

Before installing the dryer, be sure the location conforms to local codes and ordinances. In the absence of such codes or ordinances the location must conform with the National Fuel Gas Code ANSI.Z223.1 LATEST EDITION, or in Canada, the installation must conform to applicable Canadian Standards:

The dryer must be installed on a sound level floor capable of supporting its weight. Carpeting must be removed from the floor area that the dryer is to rest on.

Important

“The dryer must be installed on noncombustible floors

!only.”

The dryer must not be installed or stored in an area where it will be exposed to water and/or weather.

The dryer is for use in noncombustible locations.

Provisions for adequate air supply must be provided as noted in this manual (refer to Fresh Air Supply Requirements).

Clearance provisions must be made from noncombustible construction as noted in this manual (refer toDryer Enclosure Requirements).

Provisions must be made for adequate clearances for servicing and for operation as noted in this manual (refer to Dryer Enclosure Requirements).

Dryer must be exhausted to the outdoors as noted in this manual (refer to Exhaust Requirements).

Dryer must be located in an area where correct exhaust venting can be achieved as noted in this manual (refer to Exhaust Requirements).

Important

Dryer should be located where a minimum amount

!of exhaust duct will be necessary.

The dryer must be installed with a proper exhaust duct connection to the outside.

The dryer must be installed with provisions for adequate combustion and

Caution

This dryer produces combustible lint and must be

!exhausted to the outdoors. Every 6 months, inspect ![]() the exhaust ducting and remove any lint build up.

the exhaust ducting and remove any lint build up.

Important

Dryer must be installed in a location/environment,

!which the ambient temperature remains between

40º F (4.44º C) and 130º F (54.44º C).

4 | American Dryer Corp. |

|