HGM300 Refrigerant Gas Leak Monitor

Dual Loop 4 to 20 mAdc Scrolling Output

Converting 4 to 20 mAdc to 1 to 5 V dc Output

Loop #1 indicates the sample zone number; i.e. 5 mAdc = Zone #1 … 20 mAdc = Zone #16. The output of Loop #1 will be fixed by the number of sampling zone solenoid blocks attached to the main board. The exception to this rule is that sampling zones will be skipped if the sample tube length is set to “0” feet in the zone set up menu. This also affects the 4 to 20 mAdc output so that these skipped sampling zones are also skipped here.

Loop #2 scrolls with Loop #1 and provides the actual reading of any refrigerant gas detected for the companion sampling zone in Loop #1. The scale value for Loop #2 is a nominal 0 to 1,000 ppm = 4 to 20 mAdc. This can be adjusted, however, for better resolution. On the HGM setup screen #2, “Loop #2 Factor” can be reset so as to change output resolution. The factory default value is 0.0160 MA/PPM or “0 to 1,000” ppm. If the resolution needs to be changed simply divide 16 mA by the maximum desired value; example: 16mA/500 ppm = 0.0320 which would be entered as the new “LOOP2 FACTOR”. PLEASE NOTE: THERE IS ONLY 1 LOOP

FACTOR FOR ALL SAMPLING ZONES IN THE HGM300 MONITOR; I.E. ADJUSTING ONE SAMPLING ZONE OUTPUT CHANGES ALL SAMPLING ZONE OUTPUTS!

These output loops scroll together. Their output signals remain as a function of the next sampling zone’s total measurement time. As an example: total measuring time consists of the draw time required to insure a fresh sample has been drawn the full length of the zone sample tube, as entered on the “Zone Setup Screen”, plus the 12 seconds required to average the 16 measurement readings. In other words, the 4 to 20 mAdc values presented by Loops #1 and #2 represent the previous sampling zone measured. These output values will be held as long as required to measure the sampling zone currently being observed.

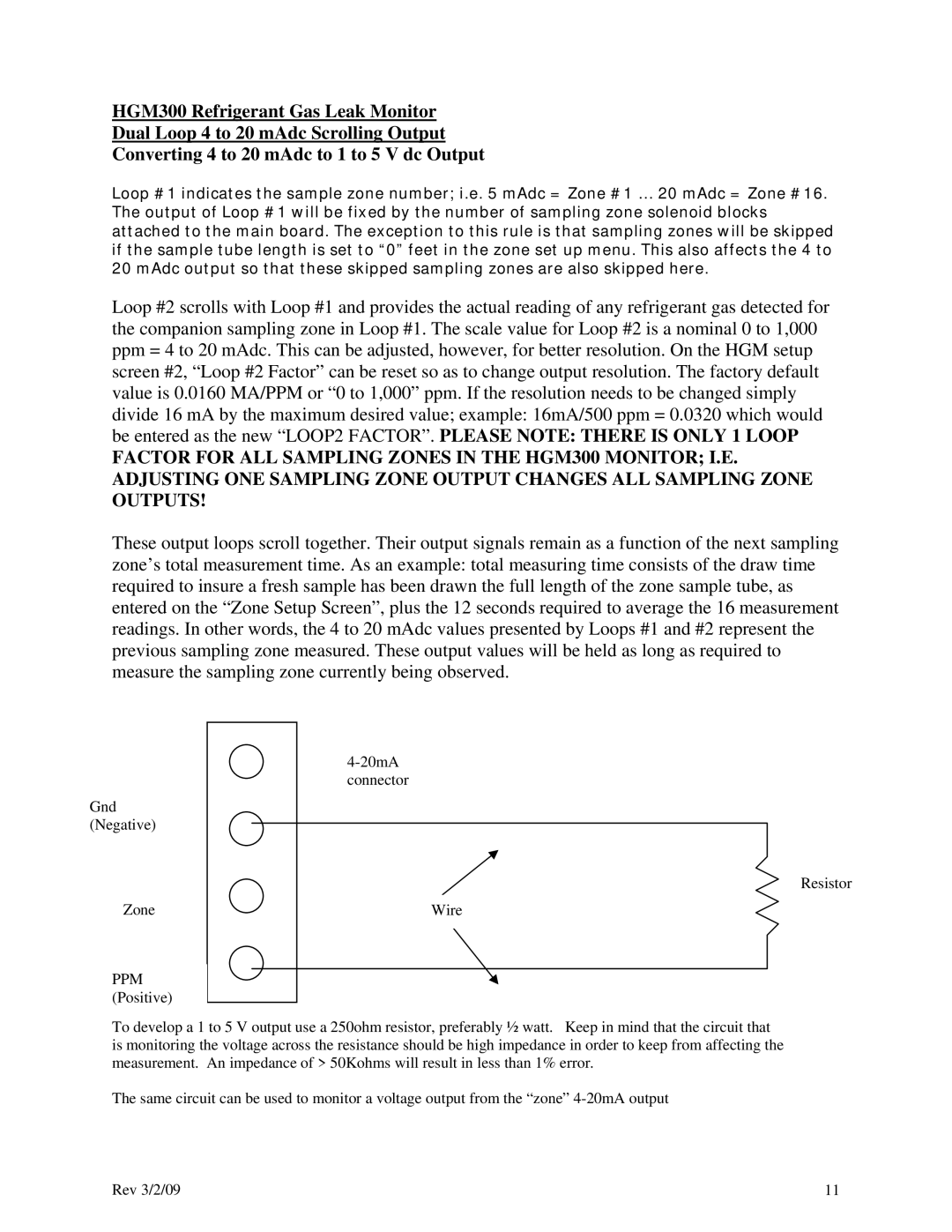

Gnd (Negative)

Zone

PPM (Positive)

Resistor

Wire

To develop a 1 to 5 V output use a 250ohm resistor, preferably ½ watt. Keep in mind that the circuit that is monitoring the voltage across the resistance should be high impedance in order to keep from affecting the measurement. An impedance of > 50Kohms will result in less than 1% error.

The same circuit can be used to monitor a voltage output from the “zone”

Rev 3/2/09 | 11 |