TABLE 3 – TERMINAL BLOCK WIRING INFORMATION

Designation | Connection | Supply Wire Gauge (AWG - Cu) | Maximum Tightening Torque | ||

Minimum | Maximum | ||||

|

| ||||

|

|

| |||

AC Line Input | L1, L2 | 22 | 12 | 12 | |

|

|

|

|

| |

Motor | U, V, W | 22 | 12 | 12 | |

|

|

|

|

| |

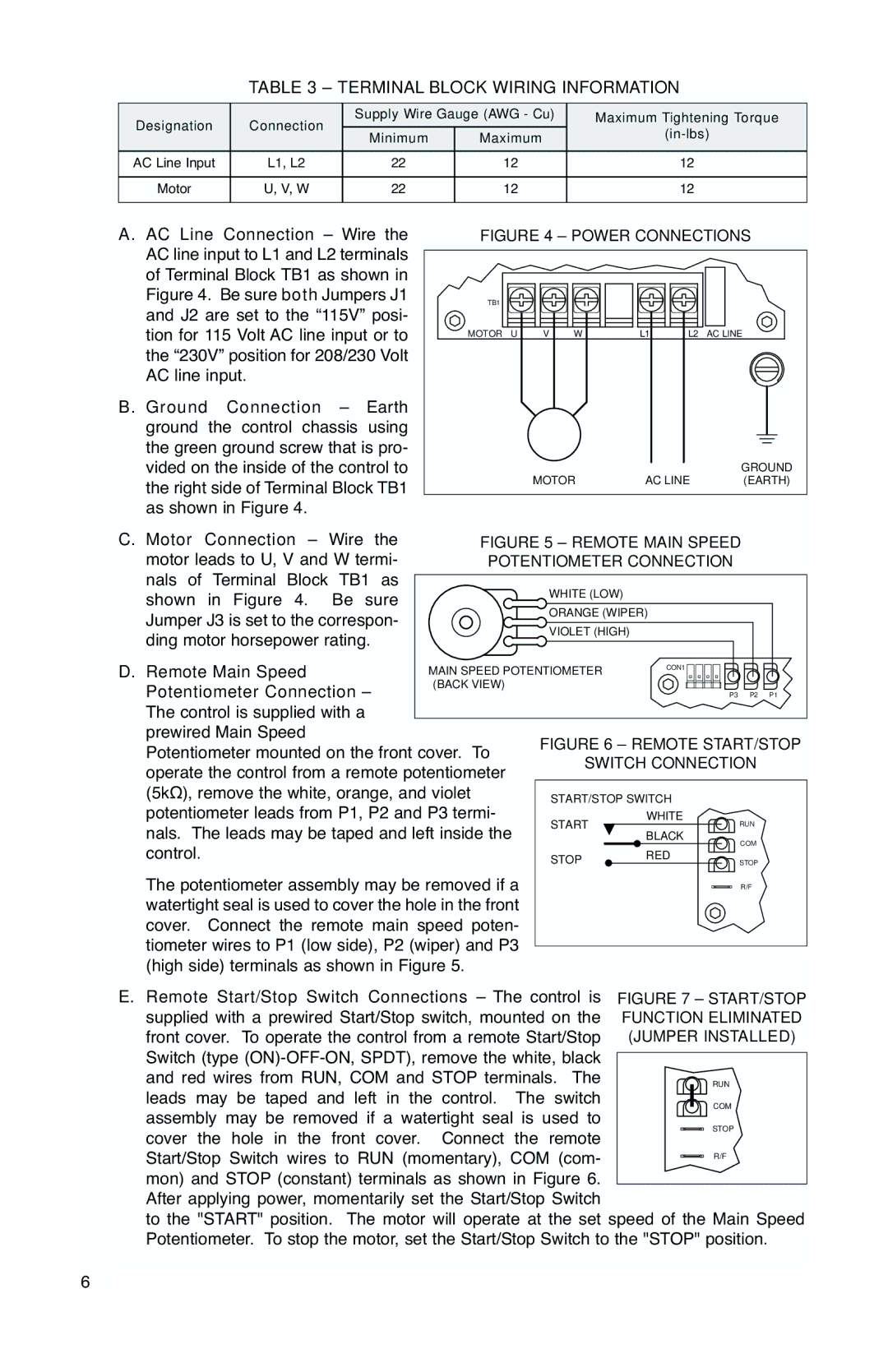

A. AC Line Connection – Wire the AC line input to L1 and L2 terminals of Terminal Block TB1 as shown in Figure 4. Be sure both Jumpers J1 and J2 are set to the “115V” posi- tion for 115 Volt AC line input or to the “230V” position for 208/230 Volt AC line input.

B. Ground Connection – Earth ground the control chassis using the green ground screw that is pro- vided on the inside of the control to the right side of Terminal Block TB1 as shown in Figure 4.

FIGURE 4 – POWER CONNECTIONS

TB1 |

|

|

|

|

|

|

MOTOR | U | V | W | L1 | L2 | AC LINE |

|

| MOTOR | AC LINE | GROUND | ||

|

| (EARTH) | ||||

C. Motor Connection – Wire the | FIGURE 5 – REMOTE MAIN SPEED | ||||||

motor leads to U, V and W termi- | POTENTIOMETER CONNECTION | ||||||

nals of | Terminal | Block | TB1 as |

| WHITE (LOW) |

| |

shown | in Figure | 4. | Be sure |

|

| ||

| ORANGE (WIPER) | ||||||

Jumper J3 is set to the correspon- |

| ||||||

| VIOLET (HIGH) |

| |||||

ding motor horsepower rating. |

|

| |||||

|

|

| |||||

D. Remote Main Speed |

| MAIN SPEED POTENTIOMETER | CON1 | ||||

|

| ||||||

Potentiometer Connection – | (BACK VIEW) |

|

| ||||

|

| P3 P2 P1 | |||||

The control is supplied with a |

|

|

| ||||

prewired Main Speed |

|

| FIGURE 6 – REMOTE START/STOP | ||||

Potentiometer mounted on the front cover. To | |||||||

SWITCH CONNECTION | |||||||

operate the control from a remote potentiometer | |||||||

|

| ||||||

(5kΩ), remove the white, orange, and violet | START/STOP SWITCH | ||||||

potentiometer leads from P1, P2 and P3 termi- | |||||||

START | WHITE | ||||||

nals. The leads may be taped and left inside the | RUN | ||||||

| BLACK | ||||||

control. |

|

|

|

|

| COM | |

|

|

|

| STOP | RED | ||

|

|

|

|

| STOP | ||

The potentiometer assembly may be removed if a |

| R/F | |||||

watertight seal is used to cover the hole in the front |

|

| |||||

cover. Connect the remote main speed poten- |

|

| |||||

tiometer wires to P1 (low side), P2 (wiper) and P3 |

|

| |||||

(high side) terminals as shown in Figure 5. |

|

| |||||

E. Remote Start/Stop Switch Connections – The control is supplied with a prewired Start/Stop switch, mounted on the front cover. To operate the control from a remote Start/Stop Switch (type

to the "START" position. The motor will operate at the set speed of the Main Speed Potentiometer. To stop the motor, set the Start/Stop Switch to the "STOP" position.

6