TABLE 4 – FAULT RECOVERY & RESETTING THE CONTROL*

Fault | Auto Mode | Manual Mode | Auto or Manual Mode | |

with Start/Stop Switch Installed | with Start/Stop Switch Installed | with Start/stop Switch Removed | ||

| ||||

Undervoltage | Control will automatically reset. | Reset the control with the | Control will automatically reset. | |

Start/Stop Switch. | ||||

|

|

| ||

|

|

|

| |

Overvoltage | Control will automatically reset. | Reset the control with the | Control will automatically reset. | |

Start/Stop Switch. | ||||

|

|

| ||

|

|

|

| |

Short Circuit | Control will automatically reset. | Reset the control with the | Control will automatically reset. | |

Start/Stop Switch. | ||||

|

|

| ||

|

|

|

| |

I2t | Reset the control with the | Reset the control with the | Disconnect and reconnect the AC | |

| Start/Stop Switch. | Start/Stop Switch. | line. |

*Fault must be cleared before the control can be reset.

WARNING! The motor will automatically start when the AC line is applied or a

!fault is cleared, if Jumper J4 is set to the “AUTO” or “MAN” position and the Start/Stop Switch is eliminated.

VII. AC LINE FUSING

This control does not contain AC line fuses. Most electrical codes require that each ungrounded conductor contain circuit protection. It is recommended to install a 20 Amp fuse (Littelfuse 326, Buss ABC or equivalent) or a circuit breaker in series with each ungrounded conductor. Check all electrical codes that apply to the application. Do not fuse motor leads.

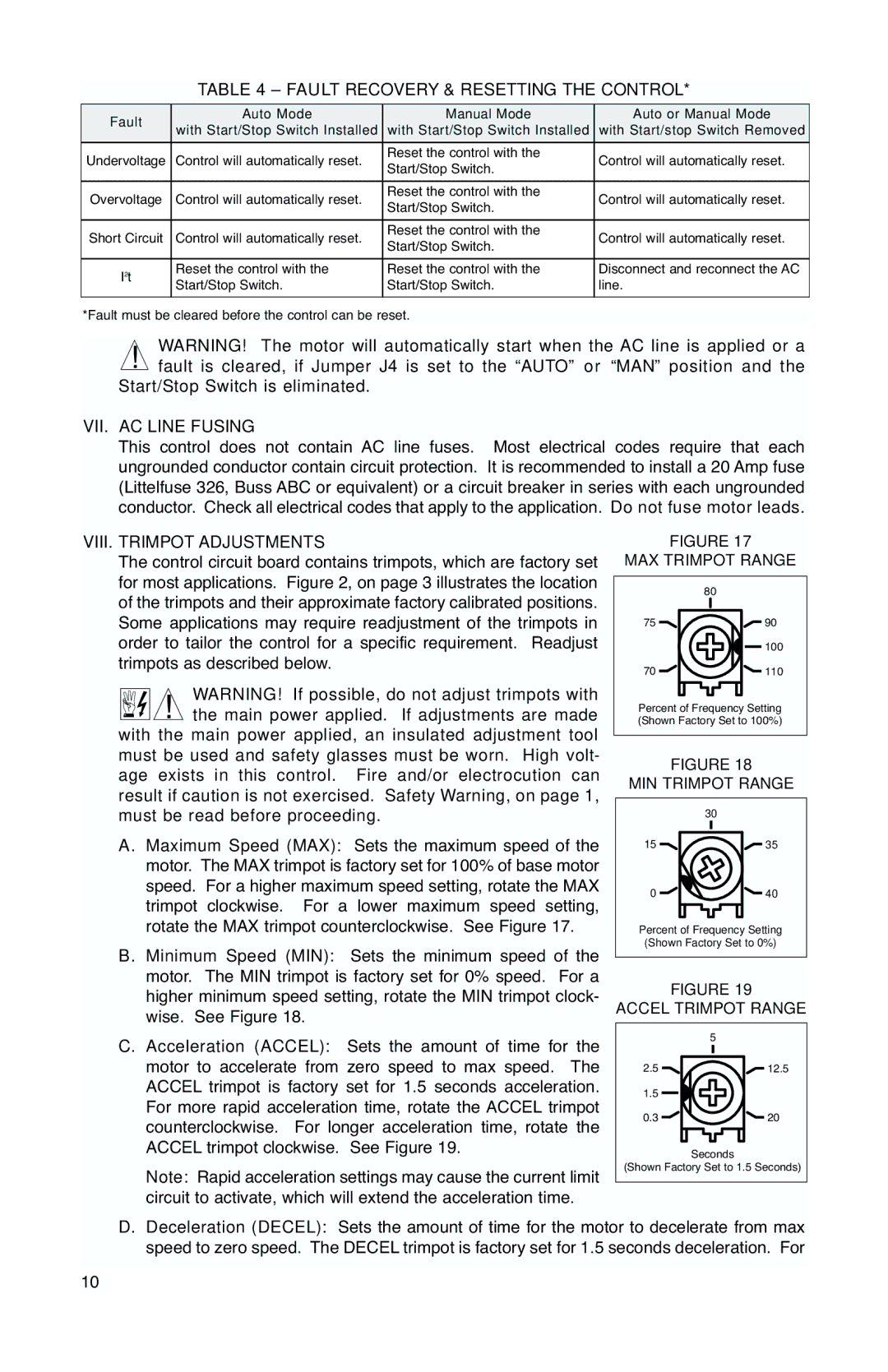

VIII. TRIMPOT ADJUSTMENTS

The control circuit board contains trimpots, which are factory set for most applications. Figure 2, on page 3 illustrates the location of the trimpots and their approximate factory calibrated positions. Some applications may require readjustment of the trimpots in order to tailor the control for a specific requirement. Readjust trimpots as described below.

WARNING! If possible, do not adjust trimpots with ![]() ! the main power applied. If adjustments are made with the main power applied, an insulated adjustment tool must be used and safety glasses must be worn. High volt- age exists in this control. Fire and/or electrocution can result if caution is not exercised. Safety Warning, on page 1, must be read before proceeding.

! the main power applied. If adjustments are made with the main power applied, an insulated adjustment tool must be used and safety glasses must be worn. High volt- age exists in this control. Fire and/or electrocution can result if caution is not exercised. Safety Warning, on page 1, must be read before proceeding.

A.Maximum Speed (MAX): Sets the maximum speed of the motor. The MAX trimpot is factory set for 100% of base motor speed. For a higher maximum speed setting, rotate the MAX trimpot clockwise. For a lower maximum speed setting, rotate the MAX trimpot counterclockwise. See Figure 17.

B.Minimum Speed (MIN): Sets the minimum speed of the motor. The MIN trimpot is factory set for 0% speed. For a higher minimum speed setting, rotate the MIN trimpot clock- wise. See Figure 18.

C.Acceleration (ACCEL): Sets the amount of time for the motor to accelerate from zero speed to max speed. The ACCEL trimpot is factory set for 1.5 seconds acceleration. For more rapid acceleration time, rotate the ACCEL trimpot counterclockwise. For longer acceleration time, rotate the ACCEL trimpot clockwise. See Figure 19.

Note: Rapid acceleration settings may cause the current limit circuit to activate, which will extend the acceleration time.

FIGURE 17

MAX TRIMPOT RANGE

80

75 ![]()

![]() 90

90

![]()

![]() 100

100

70 | 110 |

Percent of Frequency Setting (Shown Factory Set to 100%)

FIGURE 18

MIN TRIMPOT RANGE

| 30 |

15 | 35 |

0 | 40 |

Percent of Frequency Setting (Shown Factory Set to 0%)

FIGURE 19

ACCEL TRIMPOT RANGE

| 5 |

2.5 | 12.5 |

1.5 |

|

0.3 | 20 |

Seconds

(Shown Factory Set to 1.5 Seconds)

D.Deceleration (DECEL): Sets the amount of time for the motor to decelerate from max speed to zero speed. The DECEL trimpot is factory set for 1.5 seconds deceleration. For

10