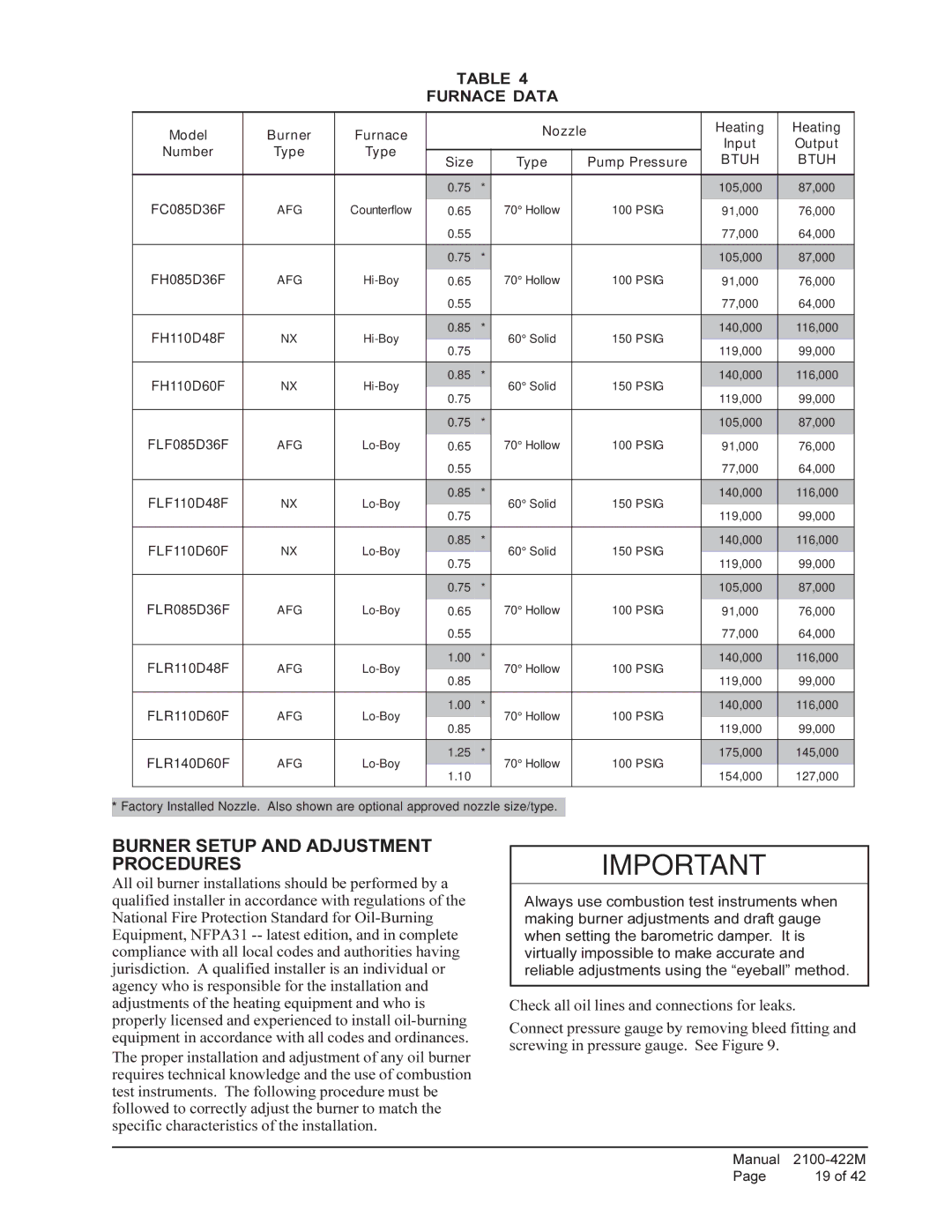

TABLE 4

FURNACE DATA

Model | Burner | Furnace |

|

| Nozzle |

| Heating | Heating | |

|

|

|

|

| |||||

|

|

|

|

| Input | Output | |||

Number | Type | Type |

|

|

|

|

| ||

Size |

| Type |

| Pump Pressure | BTUH | BTUH | |||

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

| 0.75 | * |

|

|

| 105,000 | 87,000 |

FC085D36F | AFG | Counterflow |

|

| 70° Hollow |

| 100 PSIG |

|

|

0.65 |

|

| 91,000 | 76,000 | |||||

|

|

| 0.55 |

|

|

|

| 77,000 | 64,000 |

|

|

|

|

|

|

|

|

|

|

|

|

| 0.75 | * |

|

|

| 105,000 | 87,000 |

FH085D36F | AFG |

|

| 70° Hollow |

| 100 PSIG |

|

| |

0.65 |

|

| 91,000 | 76,000 | |||||

|

|

| 0.55 |

|

|

|

| 77,000 | 64,000 |

|

|

|

|

|

|

|

|

|

|

|

|

| 0.85 | * |

|

|

| 140,000 | 116,000 |

FH110D48F | NX |

|

| 60° Solid |

| 150 PSIG |

|

| |

0.75 |

| 119,000 | 99,000 | ||||||

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| 0.85 | * |

|

|

| 140,000 | 116,000 |

FH110D60F | NX |

|

| 60° Solid |

| 150 PSIG |

|

| |

0.75 |

| 119,000 | 99,000 | ||||||

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| 0.75 | * |

|

|

| 105,000 | 87,000 |

FLF085D36F | AFG |

|

| 70° Hollow |

| 100 PSIG |

|

| |

0.65 |

|

| 91,000 | 76,000 | |||||

|

|

| 0.55 |

|

|

|

| 77,000 | 64,000 |

|

|

|

|

|

|

|

|

|

|

|

|

| 0.85 | * |

|

|

| 140,000 | 116,000 |

FLF110D48F | NX |

|

| 60° Solid |

| 150 PSIG |

|

| |

0.75 |

| 119,000 | 99,000 | ||||||

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| 0.85 | * |

|

|

| 140,000 | 116,000 |

FLF110D60F | NX |

|

| 60° Solid |

| 150 PSIG |

|

| |

0.75 |

| 119,000 | 99,000 | ||||||

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| 0.75 | * |

|

|

| 105,000 | 87,000 |

FLR085D36F | AFG |

|

| 70° Hollow |

| 100 PSIG |

|

| |

0.65 |

|

| 91,000 | 76,000 | |||||

|

|

| 0.55 |

|

|

|

| 77,000 | 64,000 |

|

|

|

|

|

|

|

|

|

|

|

|

| 1.00 | * |

|

|

| 140,000 | 116,000 |

FLR110D48F | AFG |

|

| 70° Hollow |

| 100 PSIG |

|

| |

0.85 |

| 119,000 | 99,000 | ||||||

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| 1.00 | * |

|

|

| 140,000 | 116,000 |

FLR110D60F | AFG |

|

| 70° Hollow |

| 100 PSIG |

|

| |

0.85 |

| 119,000 | 99,000 | ||||||

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| 1.25 | * |

|

|

| 175,000 | 145,000 |

FLR140D60F | AFG |

|

| 70° Hollow |

| 100 PSIG |

|

| |

1.10 |

| 154,000 | 127,000 | ||||||

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

*Factory Installed Nozzle. Also shown are optional approved nozzle size/type.

BURNER SETUP AND ADJUSTMENT PROCEDURES

All oil burner installations should be performed by a qualified installer in accordance with regulations of the National Fire Protection Standard for

IMPORTANT

Always use combustion test instruments when making burner adjustments and draft gauge when setting the barometric damper. It is virtually impossible to make accurate and reliable adjustments using the “eyeball” method.

Check all oil lines and connections for leaks.

Connect pressure gauge by removing bleed fitting and screwing in pressure gauge. See Figure 9.

Manual | |

Page | 19 of 42 |