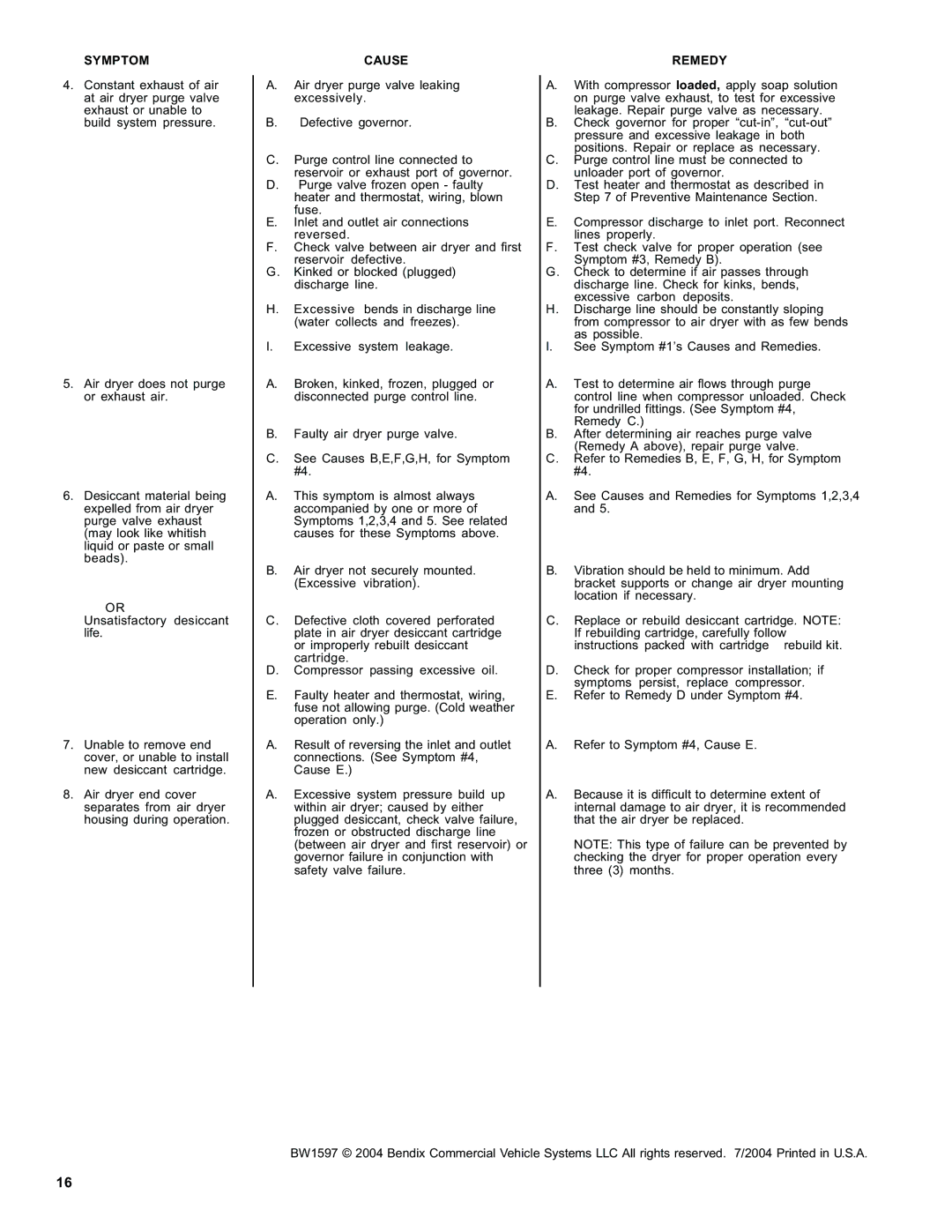

SYMPTOM

4.Constant exhaust of air at air dryer purge valve exhaust or unable to build system pressure.

5.Air dryer does not purge or exhaust air.

6.Desiccant material being expelled from air dryer purge valve exhaust (may look like whitish liquid or paste or small beads).

OR Unsatisfactory desiccant life.

7.Unable to remove end cover, or unable to install new desiccant cartridge.

8.Air dryer end cover separates from air dryer housing during operation.

CAUSE

A.Air dryer purge valve leaking excessively.

B.Defective governor.

C.Purge control line connected to reservoir or exhaust port of governor.

D.Purge valve frozen open - faulty heater and thermostat, wiring, blown fuse.

E.Inlet and outlet air connections reversed.

F.Check valve between air dryer and first reservoir defective.

G.Kinked or blocked (plugged) discharge line.

H.Excessive bends in discharge line (water collects and freezes).

I.Excessive system leakage.

A.Broken, kinked, frozen, plugged or disconnected purge control line.

B.Faulty air dryer purge valve.

C.See Causes B,E,F,G,H, for Symptom #4.

A.This symptom is almost always accompanied by one or more of Symptoms 1,2,3,4 and 5. See related causes for these Symptoms above.

B.Air dryer not securely mounted. (Excessive vibration).

C.Defective cloth covered perforated plate in air dryer desiccant cartridge or improperly rebuilt desiccant cartridge.

D.Compressor passing excessive oil.

E.Faulty heater and thermostat, wiring, fuse not allowing purge. (Cold weather operation only.)

A.Result of reversing the inlet and outlet connections. (See Symptom #4, Cause E.)

A.Excessive system pressure build up within air dryer; caused by either plugged desiccant, check valve failure, frozen or obstructed discharge line (between air dryer and first reservoir) or governor failure in conjunction with safety valve failure.

REMEDY

A.With compressor loaded, apply soap solution on purge valve exhaust, to test for excessive leakage. Repair purge valve as necessary.

B.Check governor for proper

C.Purge control line must be connected to unloader port of governor.

D.Test heater and thermostat as described in Step 7 of Preventive Maintenance Section.

E.Compressor discharge to inlet port. Reconnect lines properly.

F.Test check valve for proper operation (see Symptom #3, Remedy B).

G.Check to determine if air passes through discharge line. Check for kinks, bends, excessive carbon deposits.

H.Discharge line should be constantly sloping from compressor to air dryer with as few bends as possible.

I.See Symptom #1’s Causes and Remedies.

A.Test to determine air flows through purge control line when compressor unloaded. Check for undrilled fittings. (See Symptom #4, Remedy C.)

B.After determining air reaches purge valve (Remedy A above), repair purge valve.

C.Refer to Remedies B, E, F, G, H, for Symptom #4.

A.See Causes and Remedies for Symptoms 1,2,3,4 and 5.

B.Vibration should be held to minimum. Add bracket supports or change air dryer mounting location if necessary.

C.Replace or rebuild desiccant cartridge. NOTE: If rebuilding cartridge, carefully follow

instructions packed with cartridge rebuild kit.

D.Check for proper compressor installation; if symptoms persist, replace compressor.

E.Refer to Remedy D under Symptom #4.

A.Refer to Symptom #4, Cause E.

A.Because it is difficult to determine extent of internal damage to air dryer, it is recommended that the air dryer be replaced.

NOTE: This type of failure can be prevented by checking the dryer for proper operation every three (3) months.

BW1597 © 2004 Bendix Commercial Vehicle Systems LLC All rights reserved. 7/2004 Printed in U.S.A.

16