2.Purge Cycle Time - During normal vehicle operation, the air compressor must remain unloaded for a minimum of 20 seconds for the standard air dryer or 30 seconds for the extended purge model. These minimum purge times are required to ensure complete regeneration of the desiccant material. If the purge time is occasionally shorter than the times specified, no permanent ill effect should be expected; however, if the purge time is consistently less than the minimum, an accessory by-pass system must be installed.

3.European Air Brake Systems - Brake systems that incorporate compressors without integral unloading mechanisms, and/or utilize a compressor discharge line unloader valve, have special Bendix® AD-9®and AD-9®IPC air dryer installation requirements. Consult your local authorized Bendix parts outlet or sales representative for additional information.

4.Holset “E or QE” Type Air Compressors - In order for the AD-9 or AD-9 IPC air dryer to function properly when installed with the Holset Type “E or QE” compressor, several specialized Holset components are required. Consult your local authorized Holset parts outlet or sales representative for additional information.

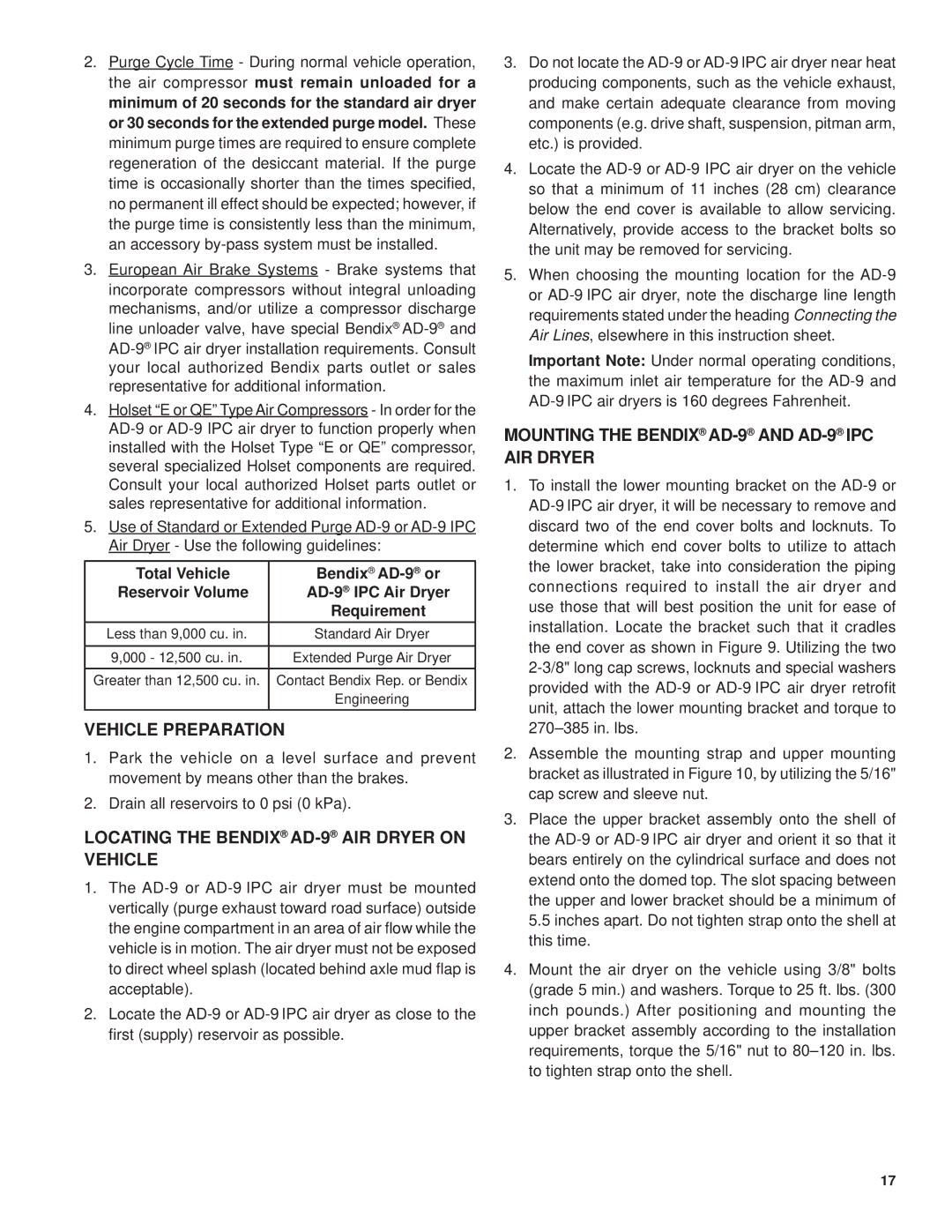

5.Use of Standard or Extended Purge AD-9 or AD-9 IPC Air Dryer - Use the following guidelines:

Total Vehicle | Bendix® AD-9®or |

Reservoir Volume | AD-9®IPC Air Dryer |

| Requirement |

Less than 9,000 cu. in. | Standard Air Dryer |

| |

9,000 - 12,500 cu. in. | Extended Purge Air Dryer |

Greater than 12,500 cu. in. | Contact Bendix Rep. or Bendix |

| Engineering |

VEHICLE PREPARATION

1.Park the vehicle on a level surface and prevent movement by means other than the brakes.

2.Drain all reservoirs to 0 psi (0 kPa).

LOCATING THE BENDIX® AD-9®AIR DRYER ON VEHICLE

1.The AD-9 or AD-9 IPC air dryer must be mounted vertically (purge exhaust toward road surface) outside the engine compartment in an area of air flow while the vehicle is in motion. The air dryer must not be exposed to direct wheel splash (located behind axle mud flap is acceptable).

2.Locate the AD-9 or AD-9 IPC air dryer as close to the first (supply) reservoir as possible.

3.Do not locate the AD-9 or AD-9 IPC air dryer near heat producing components, such as the vehicle exhaust, and make certain adequate clearance from moving components (e.g. drive shaft, suspension, pitman arm, etc.) is provided.

4.Locate the AD-9 or AD-9 IPC air dryer on the vehicle so that a minimum of 11 inches (28 cm) clearance below the end cover is available to allow servicing. Alternatively, provide access to the bracket bolts so the unit may be removed for servicing.

5.When choosing the mounting location for the AD-9 or AD-9 IPC air dryer, note the discharge line length requirements stated under the heading Connecting the Air Lines, elsewhere in this instruction sheet.

Important Note: Under normal operating conditions, the maximum inlet air temperature for the AD-9 and AD-9 IPC air dryers is 160 degrees Fahrenheit.

MOUNTING THE BENDIX® AD-9®AND AD-9®IPC AIR DRYER

1.To install the lower mounting bracket on the AD-9 or AD-9 IPC air dryer, it will be necessary to remove and discard two of the end cover bolts and locknuts. To determine which end cover bolts to utilize to attach the lower bracket, take into consideration the piping connections required to install the air dryer and use those that will best position the unit for ease of installation. Locate the bracket such that it cradles the end cover as shown in Figure 9. Utilizing the two 2-3/8" long cap screws, locknuts and special washers provided with the AD-9 or AD-9 IPC air dryer retrofit unit, attach the lower mounting bracket and torque to 270–385 in. lbs.

2.Assemble the mounting strap and upper mounting bracket as illustrated in Figure 10, by utilizing the 5/16" cap screw and sleeve nut.

3.Place the upper bracket assembly onto the shell of the AD-9 or AD-9 IPC air dryer and orient it so that it bears entirely on the cylindrical surface and does not extend onto the domed top. The slot spacing between the upper and lower bracket should be a minimum of 5.5 inches apart. Do not tighten strap onto the shell at this time.

4.Mount the air dryer on the vehicle using 3/8" bolts (grade 5 min.) and washers. Torque to 25 ft. lbs. (300 inch pounds.) After positioning and mounting the upper bracket assembly according to the installation requirements, torque the 5/16" nut to 80–120 in. lbs. to tighten strap onto the shell.