P12 Battery Charger Overview | P12 |

7521 AND 7522 BATTERY CHARGERS |

The Blue Sea Systems P12 Battery Charger is dry mount device designed for use in marine applications and other harsh environments where reliability, ease of use, and high performance are of primary importance. To this end, the P12 is designed, assembled, and tested in Bellingham, Washington, USA. Critical components, including all electronic circuitry, are of US manufacture.

The P12 is designed to charge three electrically independent batteries or battery banks. The P12 has the unique capability to individually move each battery out of the Absorption charging stage. This ensures batteries near their full charge do not continue to receive high constant voltages necessary in the Absorption stage. This is optimal treatment for long battery life. Charge Coordination integrates with the Blue Sea Systems family of Automatic Charging Relays (ACR) to force separation of the battery banks while the P12 is operational, to allow the batteries to individually exit the absorption stage. After fourteen days of continuous Float, the charger will repeat the normal charge cycle to assure good battery health.

For reliability, the P12 has a rugged cast aluminum housing with high heat dissipating capability for minimum cooling fan run times. The electronic design has given special consideration to operation in areas of inconsistent AC power quality. The P12 has a Power Factor Corrected nominal AC input range of 90V to 265V AC within which it will produce its full rated DC charging output. It will continue to produce reduced DC output to as low as 75V AC. After a shut down below 75V AC or when there is interrupted switching between AC sources, like switching between generator and shore power, the P12 will automatically perform an orderly restart.

Central to the P12’s ease of use is the large

The P12 contains charge profiles for most batteries available today, including Flooded Lead Acid (FLA), Gel, Thin Plate Pure Lead (TPPL), and Absorbed Glass Mat (AGM). In addition, a user configurable charge profile is available for other battery types.

The P12 has

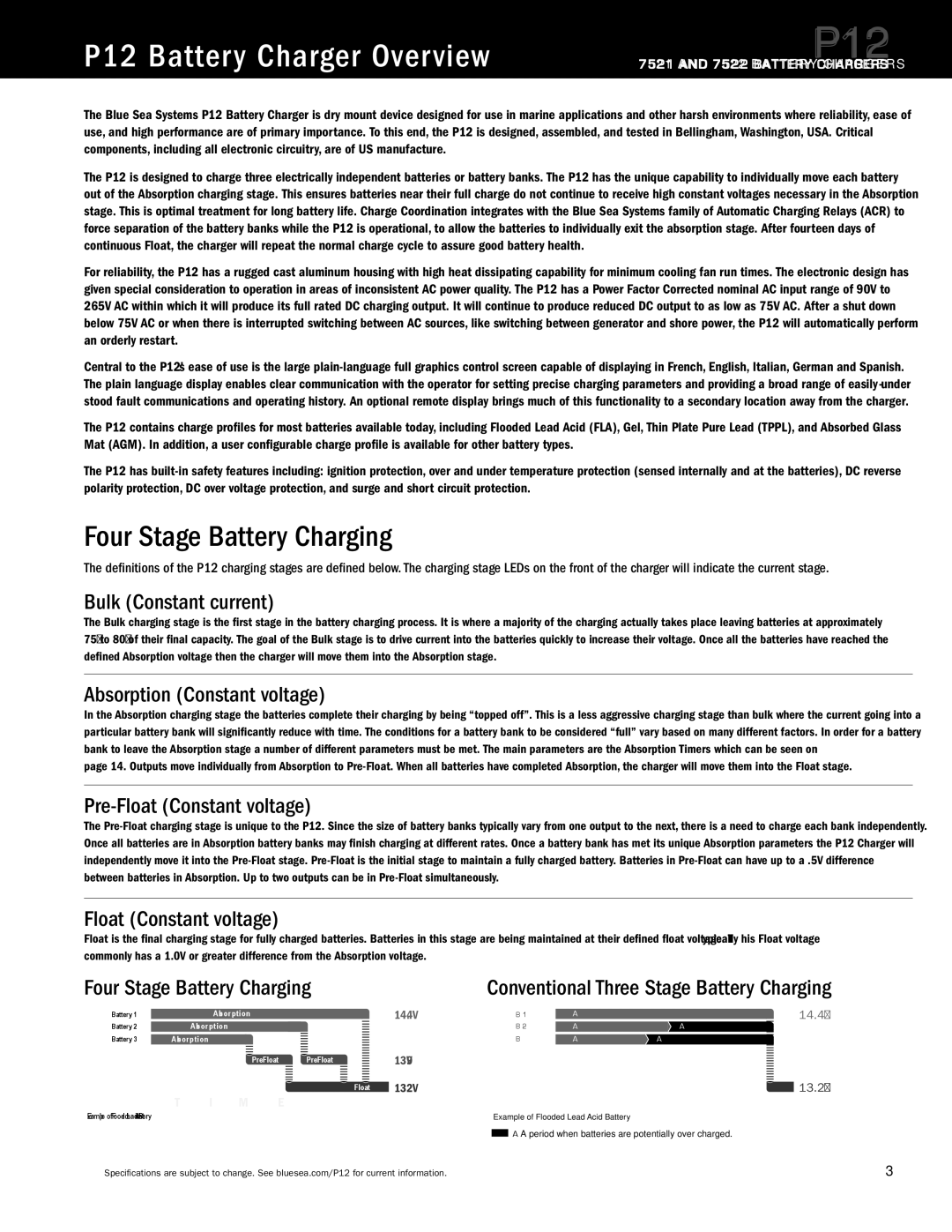

Four Stage Battery Charging

The definitions of the P12 charging stages are defined below. The charging stage LEDs on the front of the charger will indicate the current stage.

Bulk (Constant current)

The Bulk charging stage is the first stage in the battery charging process. It is where a majority of the charging actually takes place leaving batteries at approximately

75% to 80% of their final capacity. The goal of the Bulk stage is to drive current into the batteries quickly to increase their voltage. Once all the batteries have reached the defined Absorption voltage then the charger will move them into the Absorption stage.

Absorption (Constant voltage)

In the Absorption charging stage the batteries complete their charging by being “topped off”. This is a less aggressive charging stage than bulk where the current going into a particular battery bank will significantly reduce with time. The conditions for a battery bank to be considered “full” vary based on many different factors. In order for a battery bank to leave the Absorption stage a number of different parameters must be met. The main parameters are the Absorption Timers which can be seen on

page 14. Outputs move individually from Absorption to

Pre-Float (Constant voltage)

The

Float (Constant voltage)

Float is the final charging stage for fully charged batteries. Batteries in this stage are being maintained at their defined float voltage. Typically his Float voltage commonly has a 1.0V or greater difference from the Absorption voltage.

Four Stage Battery Charging

Battery 1 |

|

| Absorption |

|

|

|

|

|

| |||||

Battery 2 |

|

|

|

|

|

|

|

|

|

|

|

|

| |

| Absorption |

|

|

|

|

|

|

|

|

| ||||

Battery 3 | Absorption |

|

|

|

|

|

|

|

|

|

| |||

Bulk |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

| PreFloat | PreFloat |

| |||||||

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| Float | ||

| T | I | M | E |

|

|

|

|

|

| ||||

Example of Flooded Lead Acid Battery

14.4V

13.9V

13.2V

Conventional Three Stage Battery Charging

Battery 1 | Absorption |

|

|

|

|

| 14.4V | |

Battery 2 | Absorption |

| Forced Absorption |

|

|

|

| |

|

|

|

|

| ||||

|

|

|

|

| ||||

Battery 3 | Absorption | Forced Absorption |

|

|

| |||

|

|

| ||||||

| ||||||||

|

|

| ||||||

|

|

| ||||||

Bulk |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

| Float 13.2V | ||

| T | I | M | E | ||||

Example of Flooded Lead Acid Battery

![]() Forced Absorption: A period when batteries are potentially over charged.

Forced Absorption: A period when batteries are potentially over charged.

Specifications are subject to change. See bluesea.com/P12 for current information. | 3 |