Read Before Using

Leer antes de usar

Ver la página

24618 25618 IWH181

General Power Tool Safety Warnings

Work area safety

Electrical safety

Personal safety

Safety Rules for Cordless Impact Drivers

Battery tool use and care

Service

Wear ear protectors when impact drilling

Additional Safety Warnings

Battery/Charger

WARNING Some dust created by power sanding, sawing

WARNING Before using battery charger, read all

Battery Care

Battery Disposal

WARNING When batteries are not in tool or charger, keep them

WARNING Do not attempt to disas semble the battery or

Symbols

Symbol

Name

Designation/Explanation

Symbols continued

Functional Description and Specifications

LOCKING SLEEVE BIT BUILT IN WORK LIGHT VARIABLE SPEED TRIGGER SWITCH

BATTERY PACK RELEASE BUTTON BATTERY PACK Model number

Battery pack Charger

TRIGGER SWITCH

BATTERY PACK RELEASE BUTTON

BATTERY PACK

Battery pack

Assembly

Disconnect battery pack ! WARNING from tool before making

INSERTING AND REMOVING ACCESSORIES Model 25618 only

INSERTING AND REMOVING ACCESSORIES Models 24618, & IWH181 only

BELT CLIP Optional Accessory

BIT AND BIT STORAGE AREA BELT CLIP Optional Accessory

INSERTING AND RELEASING BATTERy PACK

FORWARD/REVERSING LEVER & TRIGGER LOCK

CHARGER INDICATORS, SyMBOLS AND MEANING Model BC630

IMPORTANT CHARGING NOTES

BATTERY PACK CHARGER RED GREEN LIGHT LIGHT

CHARGING BATTERy PACK Model BC630

FCC Caution

CHARGING BATTERy PACK Model BC660

CHARGER INDICATORS, SyMBOLS AND MEANING Model BC660

BATTERY PACK CHARGER GREEN LIGHT

Operating Tips

DRIVING WITH VARIABLE SPEED

TIGHTENING TORqUE Models 24618 & IWH181 only

The torque build-up depends on the following factors

Maintenance

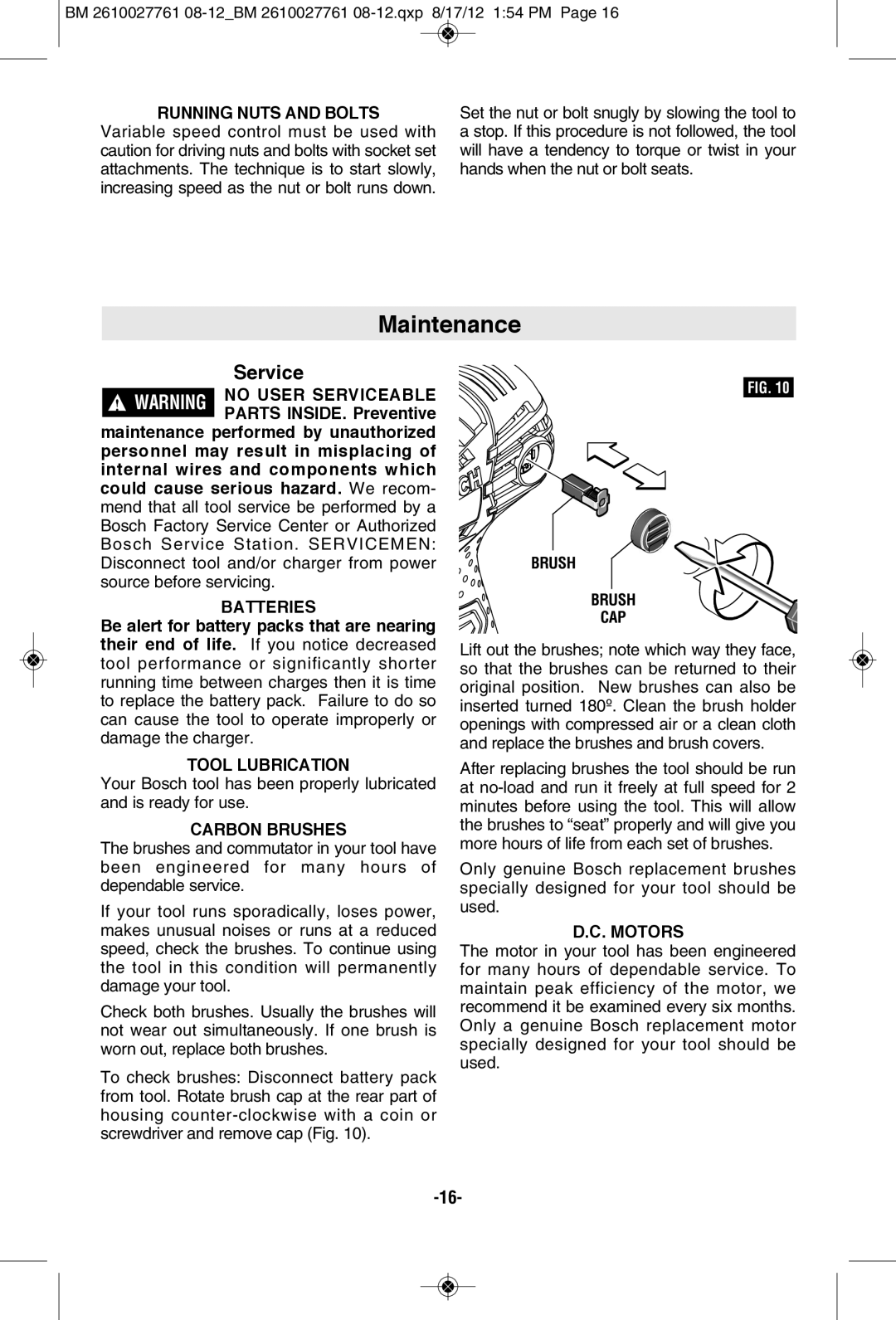

WARNING NO USER SERVICEABLE PARTS INSIDE. Preventive

RUNNING NUTS AND BOLTS

BATTERIES

Cleaning

Accessories

WARNING If an extension cord is necessary, a cord with

CONSERVEZ TOUS LES AVERTISSEMENTS ET TOUTES LES CONSIGNES

DE SÉCURITÉ POUR RÉFÉRENCE FUTURE

Sécurité du lieu de travail

Sécurité électrique

Consignes de sécurité pour les visseuses à percussion sans fil

Utilisation et entretien des outils électroportatifs

Utilisation et entretien des outils à piles

Entretien

N’utilisez pas d’embouts ou d’accessoires

Avertissements supplémentaires concernant la sécurité

Chargeur de pile

AVERTISSEMENT

Mise au rebut des piles

Entretien des piles

PILES LITHIUM-ION

Symbole

Symboles

Désignation/Explication

Symboles suite

Accessoire en option

Description fonctionnelle et spécifications

Visseuses à percussion sans fil

PRISES DAIR

Clés à chocs à percussion sans fil

BOUTON DE DÉCLENCHEMENT DU BLOC-PILES

Numéro de modèle

IWH181

INSERTION ET RETRAIT DES ACCESSOIRES modèle 25618 seulement

INSERTION ET RETRAIT DES ACCESSOIRES

Assemblage

Consignes de fonctionnement

LEVIER DE MARCHE AVANT/ARRIÈRE ET VERROUILLAGE DE GÂCHETTE

ZONE DE RANGEMENT DES EMBOUTS modèle 25618 seulement

EMBOUT ET RANGEMENT DES EMBOUTS ATTACHE À LA CEINTURE

INSERTION ET RETRAIT DU BLOC-PILES

REMARQUES IMPORTANTES CONCERNANT LA CHARGE

TEMOINS, SYMBOLES ET SIGNIFICATION Modèle BC630

4. Si le bloc-piles ne se charge pas normale -ment

CHARGE DU BLOC-PILES Modèle BC630

Mise en garde de la FCC

BLOC-PILES CHARGEUR

CHARGE DU BLOC-PILES Modèle BC660

TEMOINS, SYMBOLES ET SIGNIFICATION Modèle BC660

BLOC-PILES CHARGEUR VOYANT VERT

Consignes de fonctionnement

ENFONCEMENT À VITESSE VARIABLE

COUPLE DE SERRAGE modèles 24618 et IWH181 seulement

L’augmentation du couple dépend des facteurs suivants

Entretien

POSE DES ÉCROUS ET DES BOULONS

IL N’EXISTE À

PILES

Accessoires

Nettoyage

Advertencias generales de seguridad para herramientas mecánicas

Seguridad del área de trabajo

Seguridad eléctrica

Seguridad personal

Uso y cuidado de las herramientas alimentadas por baterías

Normas de seguridad para atornilladores de percusión inalámbricos

Servicio de ajustes y reparaciones

Advertencias de seguridad adicionales

Batería/cargador

baterías, lea todas las

baterías

Eliminación de las baterías

Cuidado de las baterías

BATERÍAS DE IONES DE LITIO

Símbolos

Símbolo

Nombre

Designación/explicación

Símbolos continuación

Descripción funcional y especificaciones

Atornilladores de percusión inalámbricos

ABERTURAS DE

MANGUITO DE

Aprietatuercas de percusión inalámbrico

ACCIONADOR

DE SALIDA

24618

Ensamblaje

Instrucciones de funcionamiento

INSERCIÓN Y REMOCIÓN DE ACCESORIOS modelo 25618 solamente

BROCA DESTORNILLADORA PORTABROCA BROCA DESTORNILLADORA

PALANCA DE AVANCE/INVERSIÓN Y CIERRE DEL GATILLO

LUZ DE TRABAJO INCORPORADA

modelo 25618 solamente

CLIP DE CINTURÓN accesorio opcional

NOTAS IMPORTANTES PARA CARGAR

INDICADORES, SIMBOLOS Y SIGNIFICADO Modelo BC630

CARGA DEL PAQUETE DE BATERÍAS Modelo BC630

Aviso de precaución de la FCC

PAQUETE DE BATERÍAS CARGADOR

CARGA DEL PAQUETE DE BATERÍAS Modelo BC660

INDICADORES, SIMBOLOS Y SIGNIFICADO Modelo BC660

PAQUETE DE BATERÍAS CARGADOR LUZ VERDE

Consejos de funcionamiento

PAR MOTOR DE APRIETE modelos 24618 y IWH181 solamente

El aumento de par motor depende de los siguientes factores

SUJECION CON TORNILLOS

Mantenimiento

Servicio

APRIETE DE TUERCAS Y PERNOS

NO HAY PIEZAS EN EL

Accesorios

Limpieza

BM 2610027761 08-12BM 2610027761 08-12.qxp 8/17/12 154 PM Page

Remarques Notas

BM 2610027761 08-12BM 2610027761 08-12.qxp 8/17/12 154 PM Page

LIMITED WARRANTY OF BOSCH PORTABLE AND BENCHTOP POWER TOOLS

2610027761

GARANTIE LIMITÉE DES OUTILS ÉLECTRIQUES PORTATIFS ET DÉTABLI BOSCH

2610027761