Internet Version for Reference Only

Page 24 | Bradford White |

|

|

|

|

Step 3: Press the three programming buttons to enter “ADJUST” mode (Figure 10). Press “Item” to select the programming item, and the arrow keys to adjust the setting. See section 6.2 Programming the Temperature Control if more programming instructions are needed.

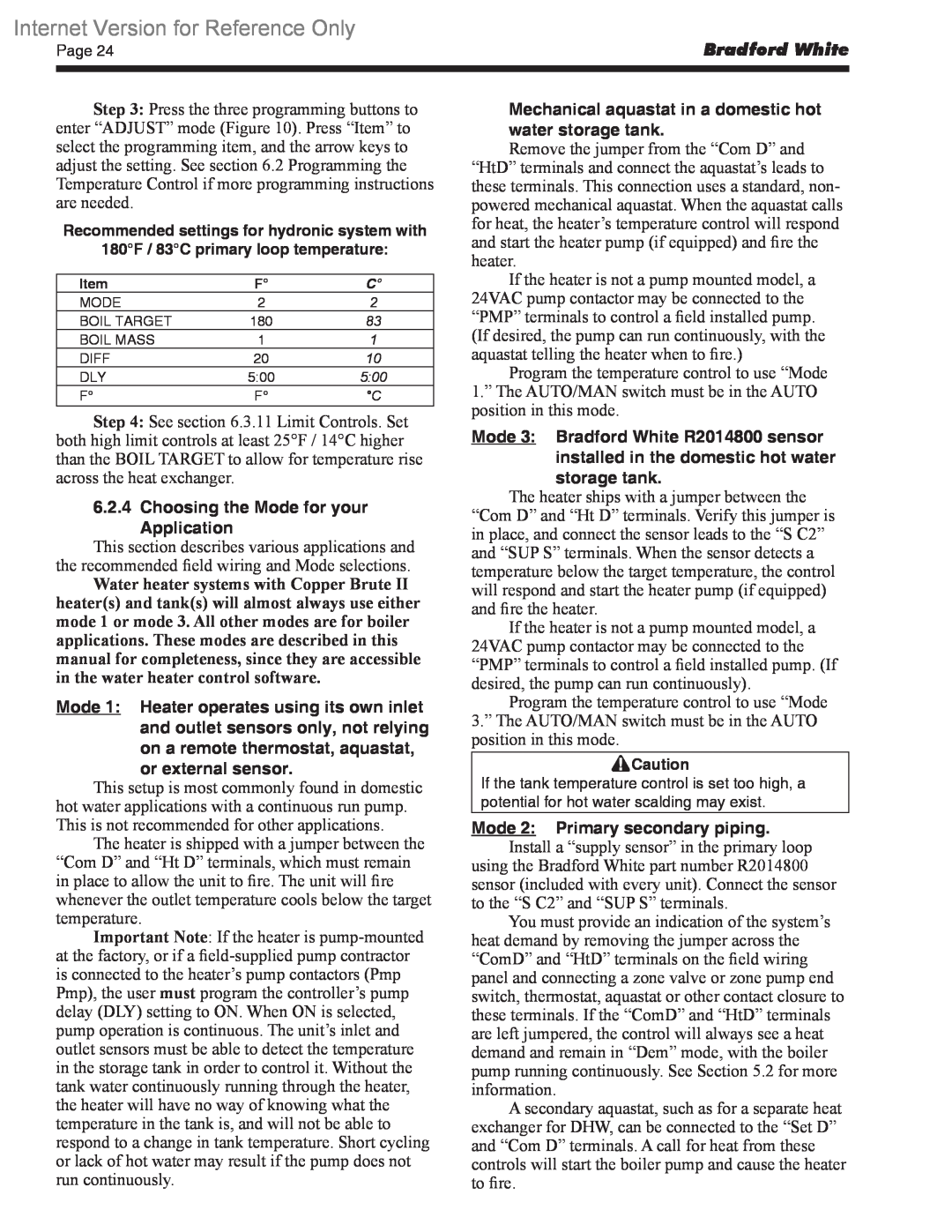

Recommended settings for hydronic system with

180°F / 83°C primary loop temperature:

Item | F° | C° |

MODE | 2 | 2 |

BOIL TARGET | 180 | 83 |

BOIL MASS | 1 | 1 |

DIFF | 20 | 10 |

DLY | 5:00 | 5:00 |

F° | F° | °C |

Step 4: See section 6.3.11 Limit Controls. Set both high limit controls at least 25°F / 14°C higher than the BOIL TARGET to allow for temperature rise across the heat exchanger.

6.2.4 Choosing the Mode for your Application

This section describes various applications and the recommended field wiring and Mode selections.

Water heater systems with Copper Brute II heater(s) and tank(s) will almost always use either mode 1 or mode 3. All other modes are for boiler applications. These modes are described in this manual for completeness, since they are accessible in the water heater control software.

Mode 1: Heater operates using its own inlet and outlet sensors only, not relying on a remote thermostat, aquastat, or external sensor.

This setup is most commonly found in domestic hot water applications with a continuous run pump. This is not recommended for other applications.

The heater is shipped with a jumper between the “Com D” and “Ht D” terminals, which must remain in place to allow the unit to fire. The unit will fire whenever the outlet temperature cools below the target temperature.

Important Note: If the heater is

Mechanical aquastat in a domestic hot water storage tank.

Remove the jumper from the “Com D” and “HtD” terminals and connect the aquastat’s leads to these terminals. This connection uses a standard, non- powered mechanical aquastat. When the aquastat calls for heat, the heater’s temperature control will respond and start the heater pump (if equipped) and fire the heater.

If the heater is not a pump mounted model, a 24VAC pump contactor may be connected to the “PMP” terminals to control a field installed pump. (If desired, the pump can run continuously, with the aquastat telling the heater when to fire.)

Program the temperature control to use “Mode 1.” The AUTO/MAN switch must be in the AUTO position in this mode.

Mode 3: Bradford White R2014800 sensor installed in the domestic hot water storage tank.

The heater ships with a jumper between the “Com D” and “Ht D” terminals. Verify this jumper is in place, and connect the sensor leads to the “S C2” and “SUP S” terminals. When the sensor detects a temperature below the target temperature, the control will respond and start the heater pump (if equipped) and fire the heater.

If the heater is not a pump mounted model, a 24VAC pump contactor may be connected to the “PMP” terminals to control a field installed pump. (If desired, the pump can run continuously).

Program the temperature control to use “Mode 3.” The AUTO/MAN switch must be in the AUTO position in this mode.

![]() Caution

Caution

If the tank temperature control is set too high, a potential for hot water scalding may exist.

Mode 2: Primary secondary piping. Install a “supply sensor” in the primary loop

using the Bradford White part number R2014800 sensor (included with every unit). Connect the sensor to the “S C2” and “SUP S” terminals.

You must provide an indication of the system’s heat demand by removing the jumper across the “ComD” and “HtD” terminals on the field wiring panel and connecting a zone valve or zone pump end switch, thermostat, aquastat or other contact closure to these terminals. If the “ComD” and “HtD” terminals are left jumpered, the control will always see a heat demand and remain in “Dem” mode, with the boiler pump running continuously. See Section 5.2 for more information.

A secondary aquastat, such as for a separate heat exchanger for DHW, can be connected to the “Set D” and “Com D” terminals. A call for heat from these controls will start the boiler pump and cause the heater to fire.