SERVICE PROCEDURE AG-IV

Burner Operation Inspection, Adjustment

Cleaning and Replacement

MAIN BURNER: Inspection, Adjustment, Cleaning and Replacement (cont.)

Step 3. | Fully inspect combustion chamber for debris or carbon build up. |

|

|

Step 4. | Be certain that thermocouple or thermopile, and pilot tube are routed correctly through the relief opening in | ||

| the combustion chamber. |

|

|

| Position thermocouple or |

|

|

| thermopile, and pilot tube. |

|

|

Step 5. | Burner should operate as adjusted in step 2 on page 20, if not, repeat procedure | Figure 38 | |

| compensating air shutter position for proper burner operation with inner door closed. | ||

|

|

| |

Step 6. | It may be necessary to clean main burner or main burner orifice to achieve proper burner operation. If | ||

| cleaning is required proceed to burner cleaning procedure below. |

|

|

BURNER CLEANING (Steel & Cast Iron)

Step 1. Slide open or remove inner combustion chamber door.

Step 2. Disconnect main burner feed line, pilot tube, and thermocouple or thermopile from gas control and remove burner assembly from combustion chamber.

NOTE: Feedline nut for natural gas control uses right hand threads,

LP control uses left hand threads.

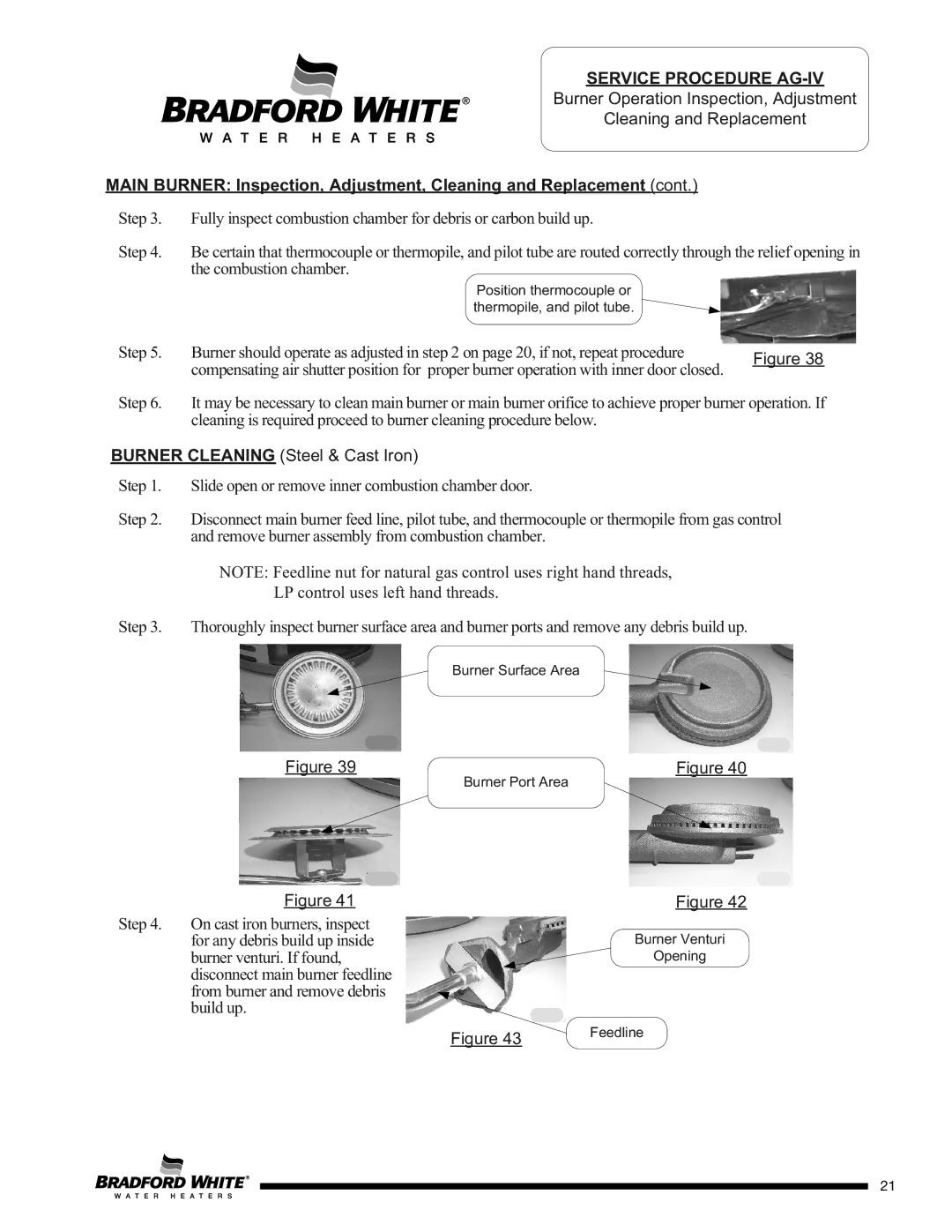

Step 3. Thoroughly inspect burner surface area and burner ports and remove any debris build up.

Burner Surface Area

Figure 39 |

| Figure 40 |

Burner Port Area

|

| Figure 41 |

|

|

| Figure 42 | |

Step 4. | On cast iron burners, inspect |

|

| ||||

| for any debris build up inside | Burner Venturi | |||||

| burner venturi. If found, | Opening | |||||

| disconnect main burner feedline |

|

| ||||

| from burner and remove debris |

|

| ||||

| build up. |

|

| ||||

|

|

| Figure 43 | Feedline | |||

|

|

|

|

|

|

|

|

|

|

|

| Page 21 |

|

| |

21