SERVICE PROCEDURE

Gas Control Replacement Thermal

Well and Chamber Door Sensor

Testing and Replacement

Thermal Well Testing | Disconnect thermal |

| well wire harness |

If Control has gone into lockout due to excessive tank temperature (four flash, 3 second pause) reset control by rotating gas control knob to “OFF” position. Then follow lighting instructions and return gas control knob to desired setpoint.

Observe heater operation. If control

continues to lockout due to excessive tank temperature, proceed to thermal well testing to determine cause.

Thermal well testing

Position gas control knob to the “OFF” position and disconnect thermal well harness from gas control.

Using a

12

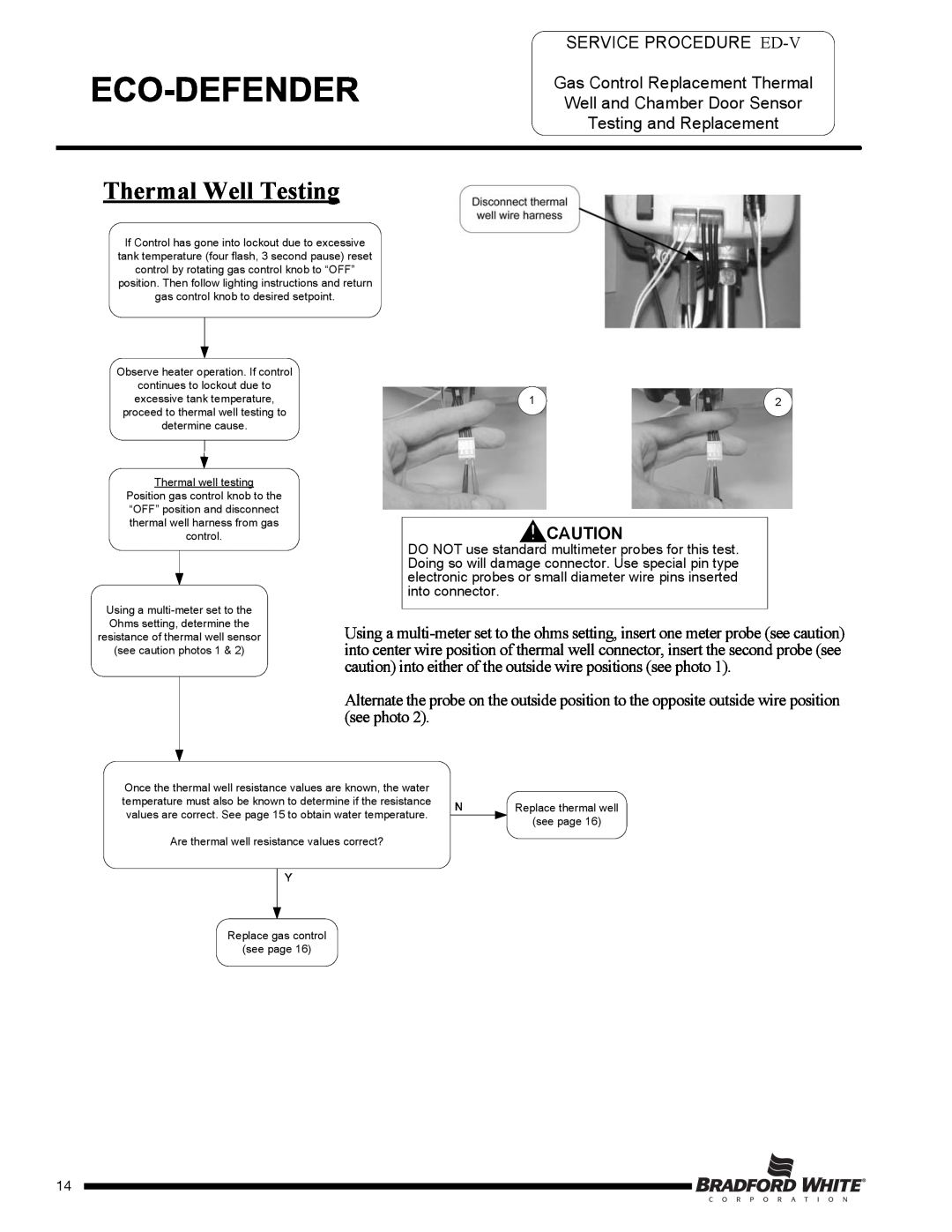

CAUTION

DO NOT use standard multimeter probes for this test. Doing so will damage connector. Use special pin type electronic probes or small diameter wire pins inserted into connector.

Using a

Alternate the probe on the outside position to the opposite outside wire position (see photo 2).

Once the thermal well resistance values are known, the water |

|

| |

temperature must also be known to determine if the resistance | N | Replace thermal well | |

values are correct. See page 15 to obtain water temperature. | |||

| (see page 16) | ||

|

|

Are thermal well resistance values correct?

Y

Replace gas control

(see page 16)

Page 14

14