SEWING BUTTONHOLES AND BUTTONS

| 2 |

1 |

|

3 | 3 |

1Buttonhole

2 Left side

3 Buttonhole appearance

If the left side is too open, turn the buttonhole

If the left side is too tight, turn the buttonhole

•This adjustment ensures both sides of the buttonhole are the same.

Sewing buttons

|

| Stitch | Stitch |

|

| |

Stitch | Pattern | Length | Width | Foot | Other | |

Name | [mm | [mm | ||||

|

| (inch)] | (inch)] |

|

| |

| 3 |

|

| Button |

| |

Zigzag | F | Any | Sewing | Darning | ||

| ||||||

Stitch |

| (1/64) | Foot | Plate | ||

|

| |||||

|

|

|

| “M” |

| |

|

|

|

|

|

|

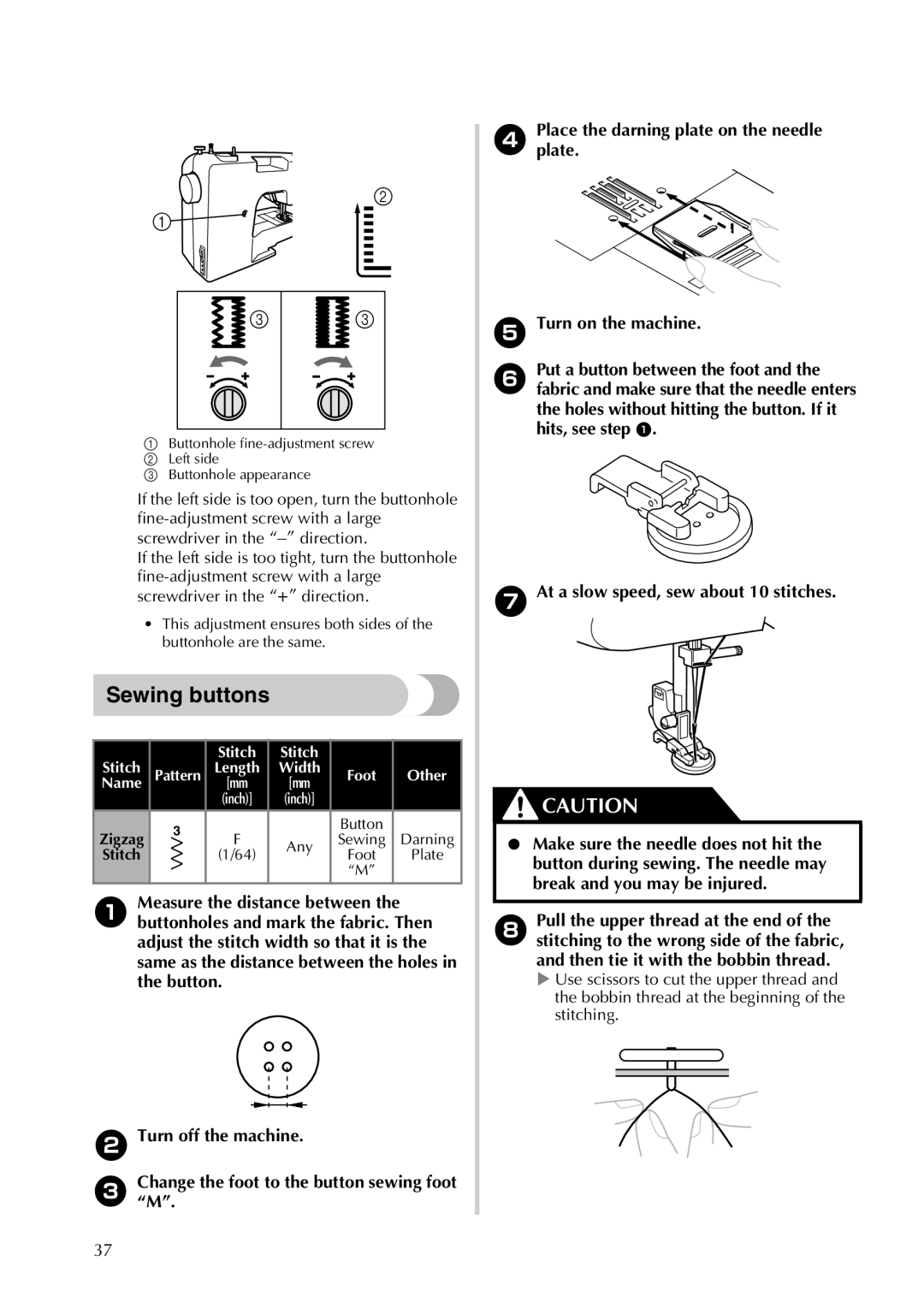

1Measure the distance between the buttonholes and mark the fabric. Then adjust the stitch width so that it is the same as the distance between the holes in the button.

2Turn off the machine.

3Change“M”. the foot to the button sewing foot

4Placeplate. the darning plate on the needle

5Turn on the machine.

6Put a button between the foot and the fabric and make sure that the needle enters the holes without hitting the button. If it hits, see step 1.

7At a slow speed, sew about 10 stitches.

![]() CAUTION

CAUTION

●Make sure the needle does not hit the button during sewing. The needle may break and you may be injured.

8Pull the upper thread at the end of the stitching to the wrong side of the fabric,

and then tie it with the bobbin thread.

X Use scissors to cut the upper thread and the bobbin thread at the beginning of the stitching.

37