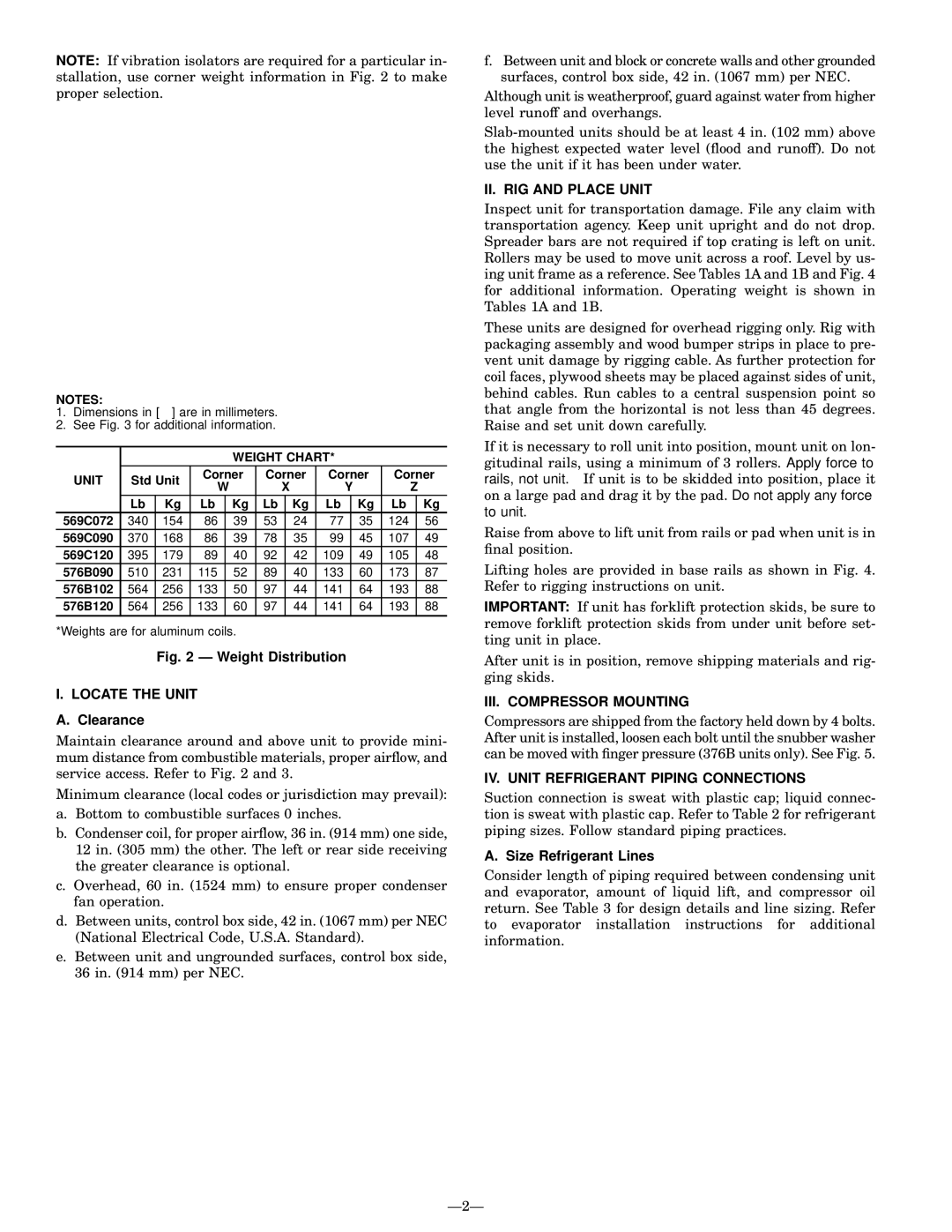

NOTE: If vibration isolators are required for a particular in- stallation, use corner weight information in Fig. 2 to make proper selection.

NOTES: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Dimensions in [ | ] are in millimeters. |

|

|

|

|

|

|

|

| ||||||

2. See Fig. 3 for additional information. |

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| WEIGHT CHART* |

|

|

|

|

| ||||

UNIT | Std Unit | Corner | Corner | Corner | Corner | ||||||||||

W |

|

| X |

| Y |

| Z | ||||||||

|

|

|

|

|

|

|

| ||||||||

| Lb |

| Kg | Lb |

| Kg | Lb |

| Kg | Lb |

| Kg | Lb |

| Kg |

569C072 | 340 |

| 154 | 86 |

| 39 | 53 |

| 24 | 77 |

| 35 | 124 |

| 56 |

569C090 | 370 |

| 168 | 86 |

| 39 | 78 |

| 35 | 99 |

| 45 | 107 |

| 49 |

569C120 | 395 |

| 179 | 89 |

| 40 | 92 |

| 42 | 109 |

| 49 | 105 |

| 48 |

576B090 | 510 |

| 231 | 115 |

| 52 | 89 |

| 40 | 133 |

| 60 | 173 |

| 87 |

576B102 | 564 |

| 256 | 133 |

| 50 | 97 |

| 44 | 141 |

| 64 | 193 |

| 88 |

576B120 | 564 |

| 256 | 133 |

| 60 | 97 |

| 44 | 141 |

| 64 | 193 |

| 88 |

*Weights are for aluminum coils.

Fig. 2 Ð Weight Distribution

I. LOCATE THE UNIT

A. Clearance

Maintain clearance around and above unit to provide mini- mum distance from combustible materials, proper air¯ow, and service access. Refer to Fig. 2 and 3.

Minimum clearance (local codes or jurisdiction may prevail):

a.Bottom to combustible surfaces 0 inches.

b.Condenser coil, for proper air¯ow, 36 in. (914 mm) one side, 12 in. (305 mm) the other. The left or rear side receiving the greater clearance is optional.

c.Overhead, 60 in. (1524 mm) to ensure proper condenser fan operation.

d.Between units, control box side, 42 in. (1067 mm) per NEC (National Electrical Code, U.S.A. Standard).

e.Between unit and ungrounded surfaces, control box side, 36 in. (914 mm) per NEC.

f.Between unit and block or concrete walls and other grounded surfaces, control box side, 42 in. (1067 mm) per NEC.

Although unit is weatherproof, guard against water from higher level runoff and overhangs.

II. RIG AND PLACE UNIT

Inspect unit for transportation damage. File any claim with transportation agency. Keep unit upright and do not drop. Spreader bars are not required if top crating is left on unit. Rollers may be used to move unit across a roof. Level by us- ing unit frame as a reference. See Tables 1A and 1B and Fig. 4 for additional information. Operating weight is shown in Tables 1A and 1B.

These units are designed for overhead rigging only. Rig with packaging assembly and wood bumper strips in place to pre- vent unit damage by rigging cable. As further protection for coil faces, plywood sheets may be placed against sides of unit, behind cables. Run cables to a central suspension point so that angle from the horizontal is not less than 45 degrees. Raise and set unit down carefully.

If it is necessary to roll unit into position, mount unit on lon- gitudinal rails, using a minimum of 3 rollers. Apply force to rails, not unit. If unit is to be skidded into position, place it on a large pad and drag it by the pad. Do not apply any force to unit.

Raise from above to lift unit from rails or pad when unit is in ®nal position.

Lifting holes are provided in base rails as shown in Fig. 4. Refer to rigging instructions on unit.

IMPORTANT: If unit has forklift protection skids, be sure to remove forklift protection skids from under unit before set- ting unit in place.

After unit is in position, remove shipping materials and rig- ging skids.

III. COMPRESSOR MOUNTING

Compressors are shipped from the factory held down by 4 bolts. After unit is installed, loosen each bolt until the snubber washer can be moved with ®nger pressure (376B units only). See Fig. 5.

IV. UNIT REFRIGERANT PIPING CONNECTIONS

Suction connection is sweat with plastic cap; liquid connec- tion is sweat with plastic cap. Refer to Table 2 for refrigerant piping sizes. Follow standard piping practices.

A. Size Refrigerant Lines

Consider length of piping required between condensing unit and evaporator, amount of liquid lift, and compressor oil return. See Table 3 for design details and line sizing. Refer to evaporator installation instructions for additional information.

Ð2Ð