After inspecting the electrical controls and wiring, replace all the panels. Start the unit, and observe at least one complete cooling cycle to ensure proper operation. If discrepancies are observed in operating cycle, or if a suspected malfunction has occurred, check each electrical component with the proper electrical instrumentation. Refer to the unit wiring label when making these checks.

| A06132 |

| |

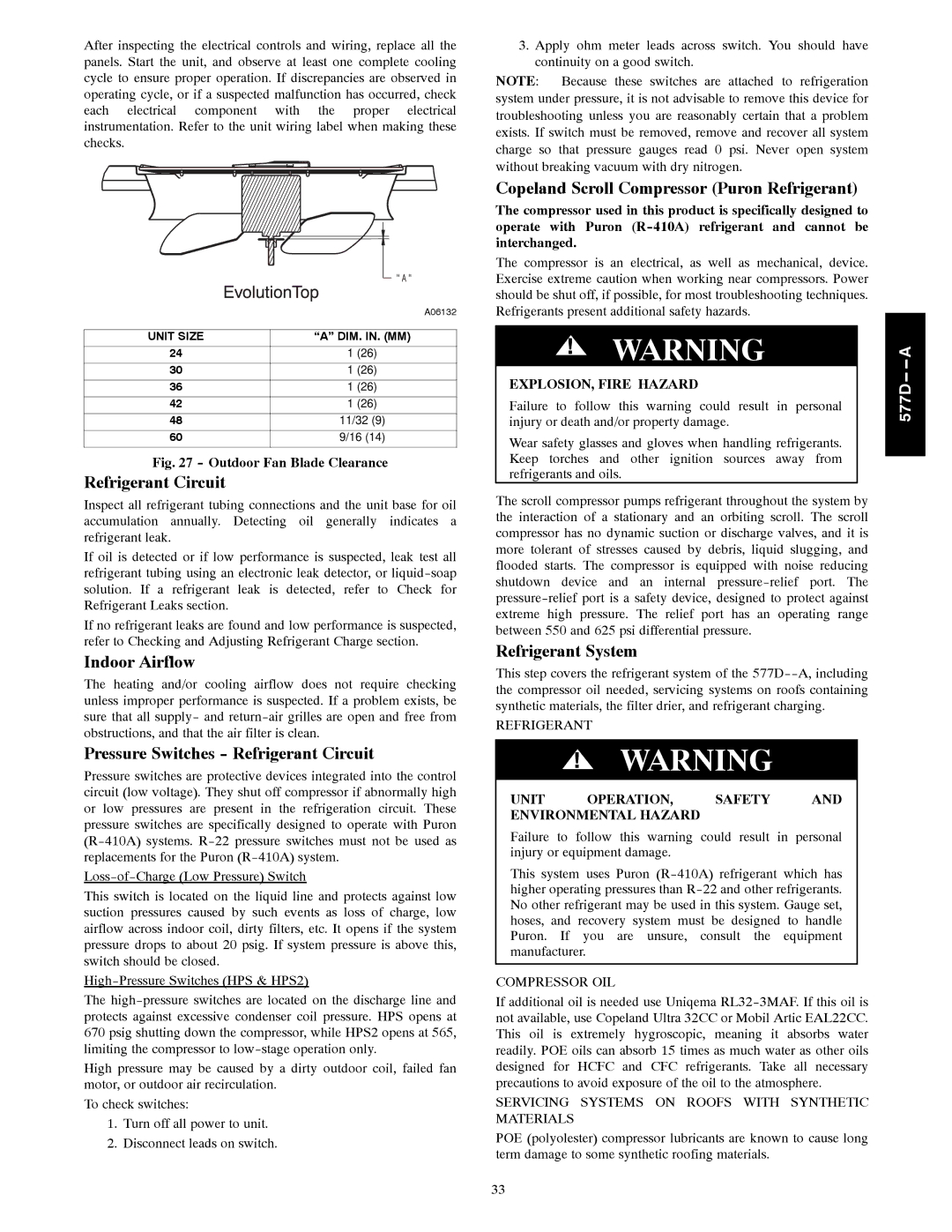

UNIT SIZE | “A” DIM. IN. (MM) |

| |

24 | 1 (26) |

| |

30 | 1 (26) |

| |

36 | 1 (26) |

| |

42 | 1 (26) |

| |

48 | 11/32 (9) |

| |

60 | 9/16 (14) |

| |

Fig. 27 - Outdoor Fan Blade Clearance

Refrigerant Circuit

Inspect all refrigerant tubing connections and the unit base for oil accumulation annually. Detecting oil generally indicates a refrigerant leak.

If oil is detected or if low performance is suspected, leak test all refrigerant tubing using an electronic leak detector, or liquid-soap solution. If a refrigerant leak is detected, refer to Check for Refrigerant Leaks section.

If no refrigerant leaks are found and low performance is suspected, refer to Checking and Adjusting Refrigerant Charge section.

Indoor Airflow

The heating and/or cooling airflow does not require checking unless improper performance is suspected. If a problem exists, be sure that all supply- and return-air grilles are open and free from obstructions, and that the air filter is clean.

Pressure Switches - Refrigerant Circuit

Pressure switches are protective devices integrated into the control circuit (low voltage). They shut off compressor if abnormally high or low pressures are present in the refrigeration circuit. These pressure switches are specifically designed to operate with Puron (R-410A) systems. R-22 pressure switches must not be used as replacements for the Puron (R-410A) system.

Loss-of-Charge (Low Pressure) Switch

This switch is located on the liquid line and protects against low suction pressures caused by such events as loss of charge, low airflow across indoor coil, dirty filters, etc. It opens if the system pressure drops to about 20 psig. If system pressure is above this, switch should be closed.

High-Pressure Switches (HPS & HPS2)

The high-pressure switches are located on the discharge line and protects against excessive condenser coil pressure. HPS opens at 670 psig shutting down the compressor, while HPS2 opens at 565, limiting the compressor to low-stage operation only.

High pressure may be caused by a dirty outdoor coil, failed fan motor, or outdoor air recirculation.

To check switches:

1.Turn off all power to unit.

2.Disconnect leads on switch.

3.Apply ohm meter leads across switch. You should have continuity on a good switch.

NOTE: Because these switches are attached to refrigeration system under pressure, it is not advisable to remove this device for troubleshooting unless you are reasonably certain that a problem exists. If switch must be removed, remove and recover all system charge so that pressure gauges read 0 psi. Never open system without breaking vacuum with dry nitrogen.

Copeland Scroll Compressor (Puron Refrigerant)

The compressor used in this product is specifically designed to operate with Puron (R-410A) refrigerant and cannot be interchanged.

The compressor is an electrical, as well as mechanical, device. Exercise extreme caution when working near compressors. Power should be shut off, if possible, for most troubleshooting techniques. Refrigerants present additional safety hazards.

!WARNING

EXPLOSION, FIRE HAZARD

Failure to follow this warning could result in personal injury or death and/or property damage.

Wear safety glasses and gloves when handling refrigerants. Keep torches and other ignition sources away from refrigerants and oils.

The scroll compressor pumps refrigerant throughout the system by the interaction of a stationary and an orbiting scroll. The scroll compressor has no dynamic suction or discharge valves, and it is more tolerant of stresses caused by debris, liquid slugging, and flooded starts. The compressor is equipped with noise reducing shutdown device and an internal pressure-relief port. The pressure-relief port is a safety device, designed to protect against extreme high pressure. The relief port has an operating range between 550 and 625 psi differential pressure.

Refrigerant System

This step covers the refrigerant system of the 577D--A, including the compressor oil needed, servicing systems on roofs containing synthetic materials, the filter drier, and refrigerant charging.

REFRIGERANT

!WARNING

UNIT OPERATION, SAFETY AND ENVIRONMENTAL HAZARD

Failure to follow this warning could result in personal injury or equipment damage.

This system uses Puron (R-410A) refrigerant which has higher operating pressures than R-22 and other refrigerants. No other refrigerant may be used in this system. Gauge set, hoses, and recovery system must be designed to handle Puron. If you are unsure, consult the equipment manufacturer.

COMPRESSOR OIL

If additional oil is needed use Uniqema RL32-3MAF. If this oil is not available, use Copeland Ultra 32CC or Mobil Artic EAL22CC. This oil is extremely hygroscopic, meaning it absorbs water readily. POE oils can absorb 15 times as much water as other oils designed for HCFC and CFC refrigerants. Take all necessary precautions to avoid exposure of the oil to the atmosphere.

SERVICING SYSTEMS ON ROOFS WITH SYNTHETIC MATERIALS

POE (polyolester) compressor lubricants are known to cause long term damage to some synthetic roofing materials.