Contents

BUNN S,SA

POST OFFICE BOX SPRINGFIELD, ILLINOIS

FAX

ST,STA STF,STFA

WARRANTY

USER NOTICES

#00882.0000

USER NOTICES Continued

#00656.0000

#02763.0000 #02765.0000 #02769.0000

Electrical Hook-Up

ELECTRICAL REQUIREMENTS

PLUMBING REQUIREMENTS

Models S & SA

4B. Models ST, STA

INITIAL SET-UP

4A. Models S & SA

4C. Models STF & STFA

START SWITCH

CLEANING

Models ST, STF, STA & STFA ON/OFF SWITCH

OPERATING CONTROLS

TROUBLESHOOTING

PROBABLE CAUSE

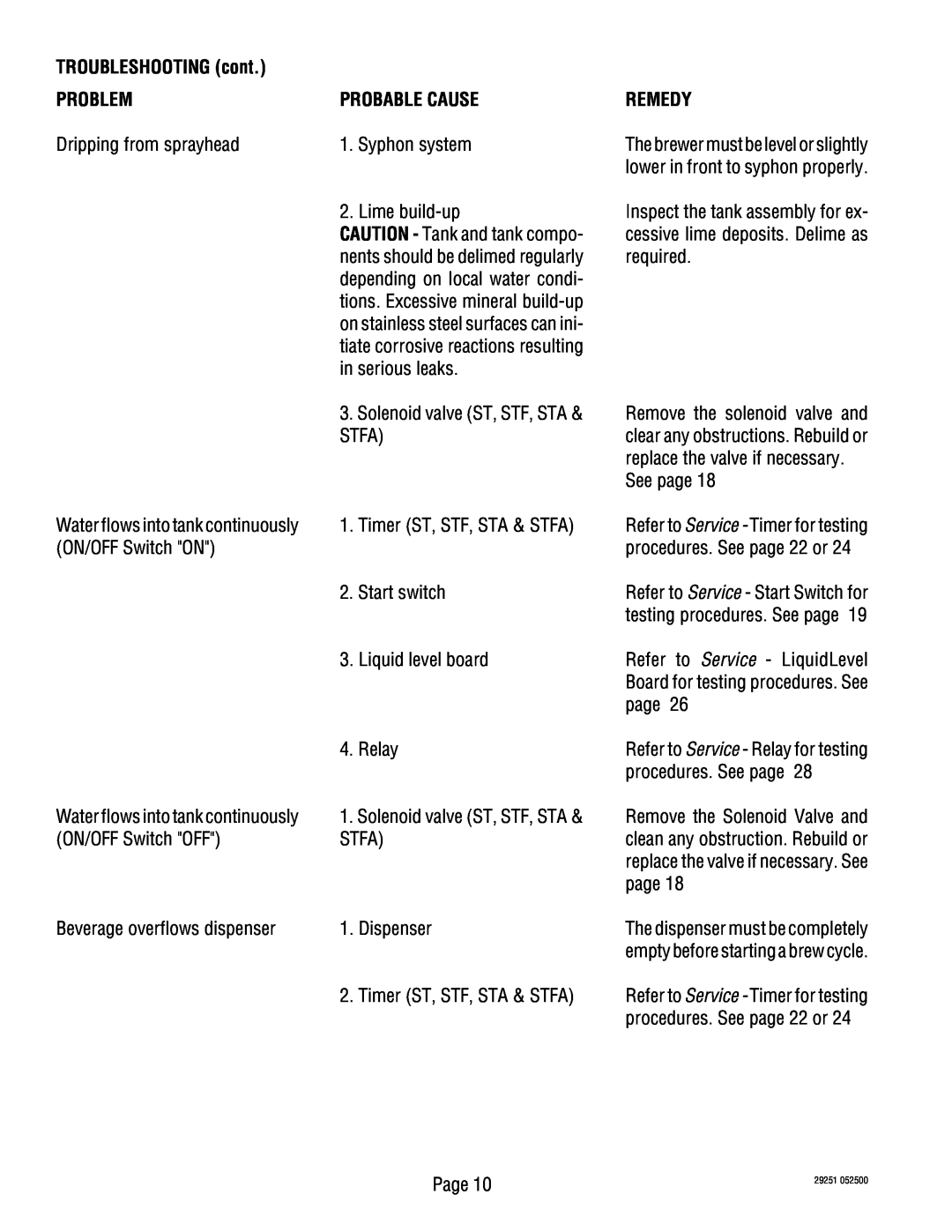

TROUBLESHOOTING cont

PROBLEM

REMEDY

TROUBLESHOOTING cont PROBLEM

Dripping from sprayhead

Beverage overflows dispenser cont Weak beverage

Brewer is making unusal noises

COMPONENT ACCESS

SERVICE

Contents

SERVICE cont

CONTROL THERMOSTAT

SERVICE cont CONTROL THERMOSTAT cont

SERVICE cont LIMIT THERMOSTAT

ON/OFF SWITCH Models ST, STA, STF & STFA

FIG. 8 SOLENOID

START SWITCH Models ST, STA, STF & STFA

SERVICE cont TANK HEATER

SERVICE cont TANK HEATER Cont

FIG. 14 BREW TIMER

SERVICE cont BREW TIMER Early Modelscont

DIGITAL BREW TIMER Late Models

FIG. 16 DIGITAL BREW TIMER

SERVICE cont DIGITAL BREW TIMER Late Modelscont

LIQUID LEVEL CONTROL BOARD Models STF & STFA

STFACont

SERVICE cont TIMER RELAY Models STF & STFA

SERVICE cont WARMER ELEMENTS

SERVICE cont THERMAL CUT-OFFModels SA, STA & STFA

Page

29251

Page

29251

Page

29251

Page

29251

Page

29251

Page

29251

Page

29251

Page

29251

Page

29251

Page

29251

Page

29251

Page

29251

Page

29251