VIII. System Start-Up

|

| WARNING | 9. | Close purge valve, continue filling the system | |||||

|

|

|

| until the pressure gauge reads the desired cold fill | |||||

Completely read, understand and follow all |

|

| pressure. Close fill valve. |

| |||||

instructions in this manual before attempting |

|

| (Note - If | ||||||

|

|

| pressure reducing valve, adjust pressure reducing | ||||||

A. Safe operation and other performance criteria were met |

|

| valve to desired cold fill pressure. Follow fill valve | ||||||

|

| manufacturer’s instructions). |

| ||||||

| with the gas manifold and control assembly provided |

|

|

| |||||

| 10. | Open isolation valve in boiler supply piping. | |||||||

| on boiler when boiler underwent tests specified in | ||||||||

| American National Standard for | 11. | Remove hose from purge valve. |

| |||||

| Pressure Steam and Hot Water Boilers, ANSI Z21.13. |

| F. Confirm that the boiler and system have no water | ||||||

B. |

|

|

| ||||||

Check Main Burners. Main burners must be properly |

| leaks. |

|

|

| ||||

| located on support bracket in Base Rear Panel, seated |

| G. Prepare to check operation. |

| |||||

| on Main Burner Orifices, and secured with hitch pin |

|

| ||||||

| 1. | Obtain gas heating value (in Btu per cubic foot) | |||||||

| clips. | ||||||||

C. Verify that the venting, water piping, gas piping |

|

| from gas supplier. |

| |||||

2. | Connect manometer to pressure tap on gas valve. | ||||||||

| and electrical system are installed properly. Refer to | ||||||||

|

|

| Use 1/8 NPT tapping provided. |

| |||||

| installation instructions contained in this manual. |

|

|

| |||||

| 3. | Temporarily turn off all other | |||||||

D. Confirm all electrical, water and gas supplies | |||||||||

4. | Turn on gas supply to the boiler gas piping. | ||||||||

| are turned off at the source and that vent is clear of | ||||||||

| obstructions. | 5. | Confirm that the supply pressure to the gas valve is | ||||||

E. FILL ENTIRE HEATING SYSTEM WITH WATER |

|

| 14 in. w.c. or less. |

| |||||

6. | Open the field installed manual gas | ||||||||

| and vent air from system. Use following procedure on | ||||||||

| a Series Loop or |

|

| located upstream of the gas valve on the boiler. | |||||

| Figure 23 to remove air from system when filling. | 7. | Using soap solution, or similar | ||||||

|

|

|

|

| solution, electronic leak detector or other approved | ||||

|

| WARNING |

|

| |||||

|

|

|

| method. Check that boiler gas piping, valves, and | |||||

|

|

|

|

| all other components are leak free. Eliminate any | ||||

The maximum operating pressure of this boiler is |

|

| |||||||

|

| leaks. |

|

|

| ||||

50 psig. Never exceed this pressure. Do not plug |

|

|

|

|

| ||||

8. | Purge gas line of air. |

| |||||||

or modify pressure relief valve. |

| ||||||||

| 1. Close full port ball valve in boiler supply piping. |

| H. Follow Lighting or Operating Instructions to place | ||||||

|

| boiler in operation. Refer to label on inside of Front | |||||||

| 2. Isolate all zones by closing zone valves or |

| |||||||

|

| Removable Panel or appropriate Figure as listed in | |||||||

|

| valves in supply and return of each zone(s). |

| Table 11. |

|

|

| ||

| 3. Attach a hose to the vertical purge valve located |

|

|

|

|

|

| ||

|

|

|

| DANGER |

|

| |||

|

| prior to the full port ball valve in the system supply |

|

|

|

|

| ||

|

|

|

|

|

|

|

| ||

|

| piping. (Note - Terminate hose in five gallon bucket |

|

|

|

|

|

| |

|

|

| Do not use matches, candles, open flames or | ||||||

|

| at a suitable floor drain or outdoor area). |

| ||||||

|

|

| other ignition source to check for leaks. | ||||||

| 4. Starting with one circuit at a time, open zone valve |

| |||||||

|

|

|

|

|

|

| |||

|

| or |

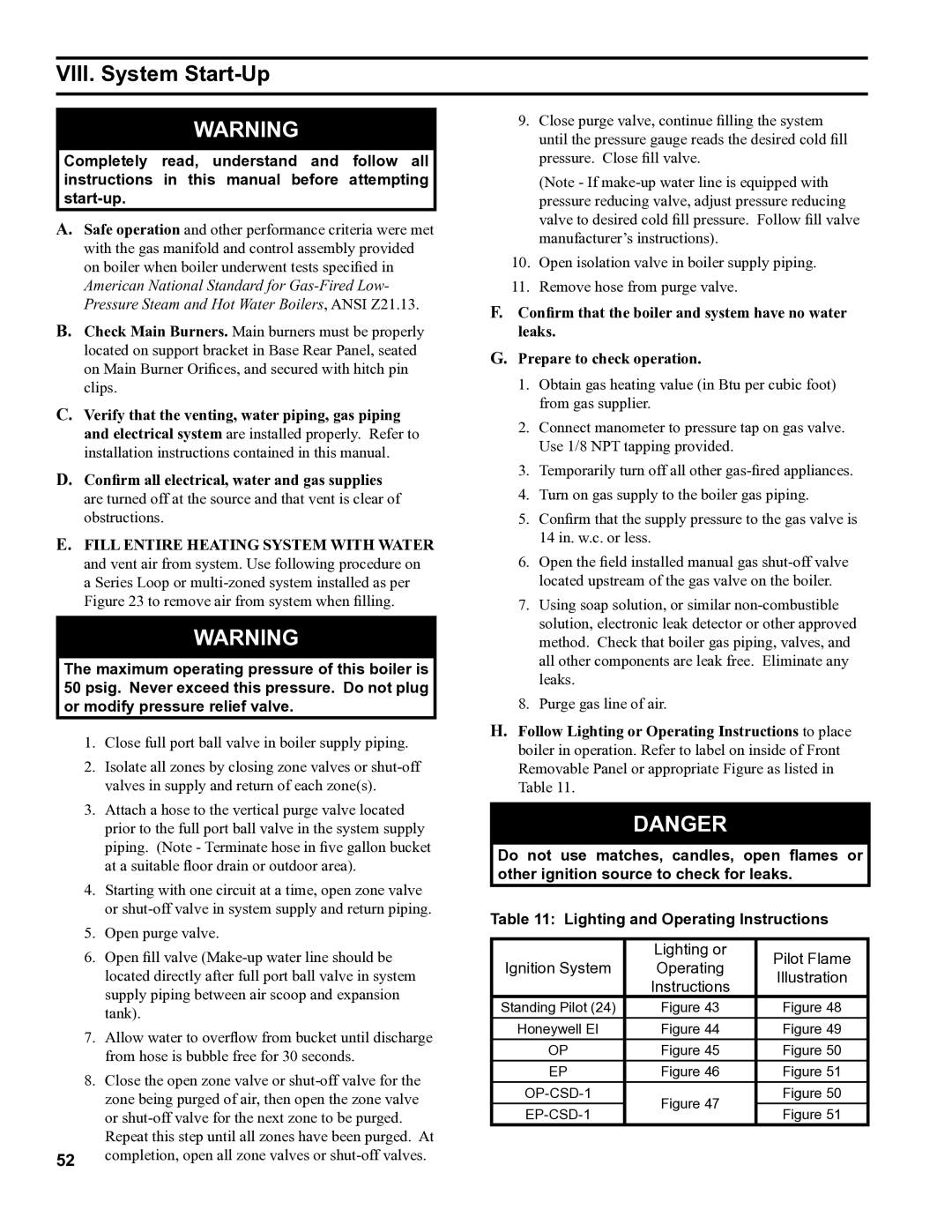

| Table 11: Lighting and Operating Instructions | |||||

| 5. | Open purge valve. |

| ||||||

|

|

|

|

|

|

| |||

| 6. | Open fill valve |

|

|

| Lighting or | Pilot Flame | ||

|

| Ignition System | Operating | ||||||

|

| located directly after full port ball valve in system |

| Illustration | |||||

|

|

|

|

| Instructions | ||||

|

| supply piping between air scoop and expansion |

|

|

|

| |||

|

|

| Standing Pilot (24) | Figure 43 | Figure 48 | ||||

|

| tank). |

| ||||||

| 7. Allow water to overflow from bucket until discharge |

| Honeywell EI | Figure 44 | Figure 49 | ||||

|

|

| OP | Figure 45 | Figure 50 | ||||

|

| from hose is bubble free for 30 seconds. |

|

| |||||

| 8. Close the open zone valve or |

|

| EP | Figure 46 | Figure 51 | |||

|

|

|

| Figure 50 | |||||

|

| zone being purged of air, then open the zone valve |

| Figure 47 | |||||

|

|

| Figure 51 | ||||||

|

| or |

|

|

| ||||

|

| Repeat this step until all zones have been purged. At |

|

|

|

|

|

| |

52completion, open all zone valves or