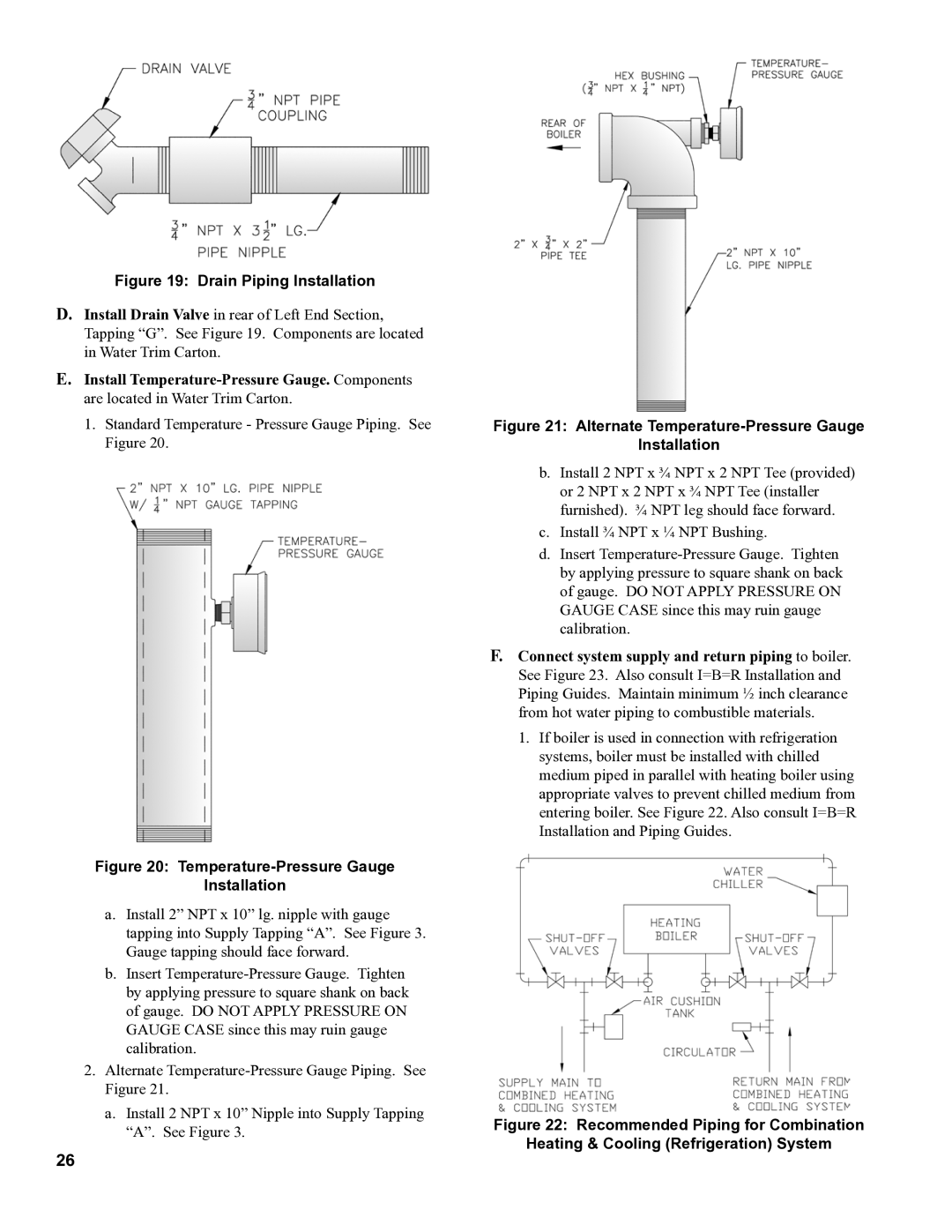

Figure 19: Drain Piping Installation

D.Install Drain Valve in rear of Left End Section, Tapping “G”. See Figure 19. Components are located in Water Trim Carton.

E.Install

1.Standard Temperature - Pressure Gauge Piping. See Figure 20.

Figure 20: Temperature-Pressure Gauge

Installation

a.Install 2” NPT x 10” lg. nipple with gauge tapping into Supply Tapping “A”. See Figure 3. Gauge tapping should face forward.

b.Insert

2.Alternate

a.Install 2 NPT x 10” Nipple into Supply Tapping “A”. See Figure 3.

Figure 21: Alternate Temperature-Pressure Gauge

Installation

b.Install 2 NPT x ¾ NPT x 2 NPT Tee (provided) or 2 NPT x 2 NPT x ¾ NPT Tee (installer furnished). ¾ NPT leg should face forward.

c.Install ¾ NPT x ¼ NPT Bushing.

d.Insert

F.Connect system supply and return piping to boiler. See Figure 23. Also consult I=B=R Installation and Piping Guides. Maintain minimum ½ inch clearance from hot water piping to combustible materials.

1.If boiler is used in connection with refrigeration systems, boiler must be installed with chilled medium piped in parallel with heating boiler using appropriate valves to prevent chilled medium from entering boiler. See Figure 22. Also consult I=B=R Installation and Piping Guides.

Figure 22: Recommended Piping for Combination

Heating & Cooling (Refrigeration) System

26