IV. Water Trim and Piping

WARNING

Failure to properly pipe boiler may result in improper operation and damage to boiler or structure.

Oxygen contamination of boiler water will cause corrosion of iron and steel boiler components, and can lead to boiler failure. Burnham’s Warranty does not cover problems caused by oxygen contamination of boiler water or scale (lime)

A. Design and install boiler and system piping to prevent oxygen contamination of boiler water and frequent water additions.

1.There are many possible causes of oxygen contamination such as:

a.Addition of excessive

b.Absorption through open tanks and fittings.

c.Oxygen permeable materials in the distribution system.

2.In order to insure long product life, oxygen sources must be eliminated. This can be accomplished by taking the following measures:

a.Repairing system leaks to eliminate the need for addition of

b.Eliminating open tanks from the system.

c.Eliminating and/or repairing fittings which allow oxygen absorption.

d.Use of

e.Isolating the boiler from the system water by installing a heat exchanger.

f.Use properly designed and operating air elimination devices in water piping.

B.Design boiler piping and flow rate to obtain proper temperature rise though the boiler. (See Table 4)

WARNING

Pressure relief valve discharge piping must be piped such that the potential of severe burns is eliminated. DO NOT pipe in any area where freezing could occur. DO NOT install any shut off valves, plugs or caps. Consult Local Codes for proper discharge piping arrangement.

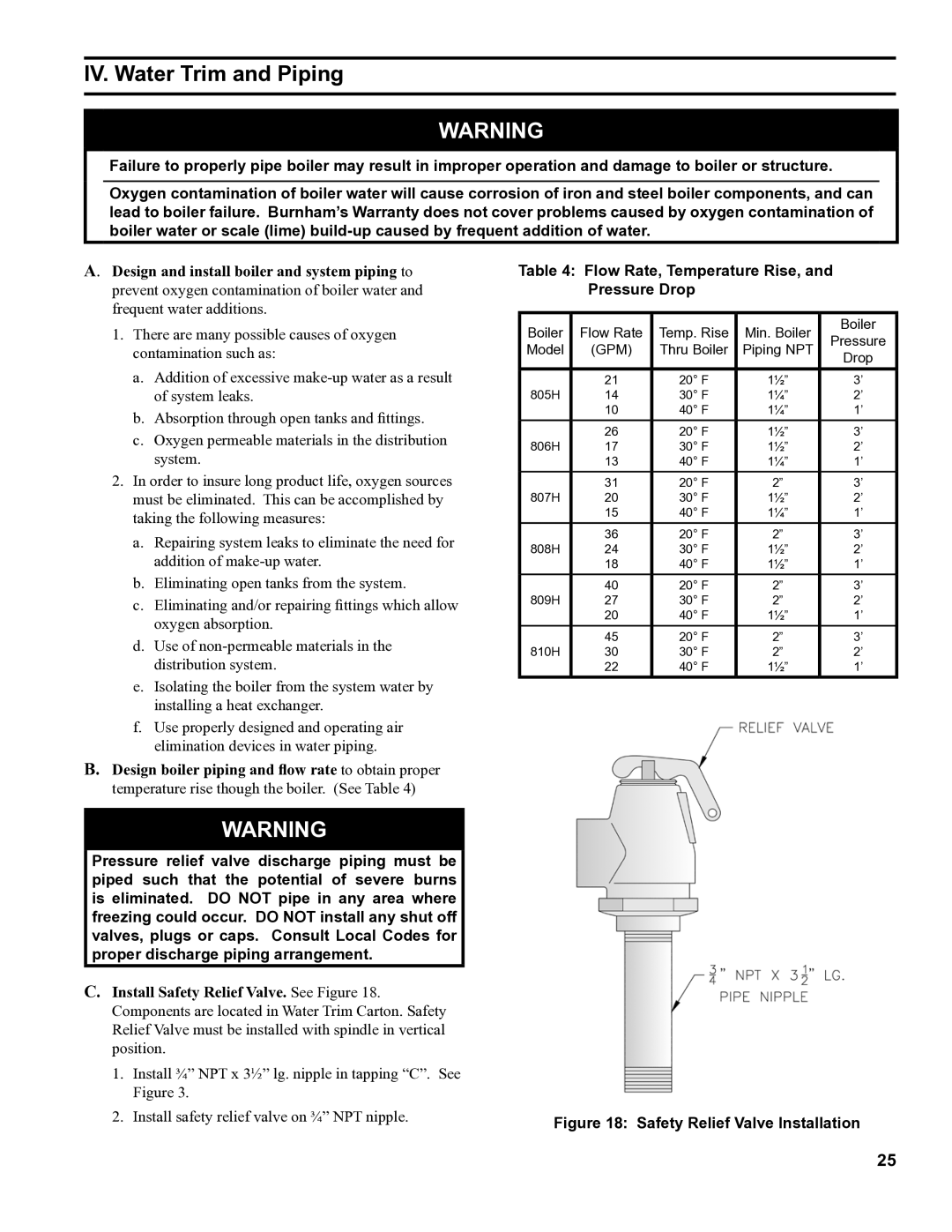

C.Install Safety Relief Valve. See Figure 18. Components are located in Water Trim Carton. Safety Relief Valve must be installed with spindle in vertical position.

1.Install ¾” NPT x 3½” lg. nipple in tapping “C”. See Figure 3.

2.Install safety relief valve on ¾” NPT nipple.

Table 4: Flow Rate, Temperature Rise, and Pressure Drop

Boiler | Flow Rate | Temp. Rise | Min. Boiler | Boiler | |

Pressure | |||||

Model | (GPM) | Thru Boiler | Piping NPT | ||

Drop | |||||

|

|

|

| ||

| 21 | 20° F | 1½” | 3’ | |

805H | 14 | 30° F | 1¼” | 2’ | |

| 10 | 40° F | 1¼” | 1’ | |

| 26 | 20° F | 1½” | 3’ | |

806H | 17 | 30° F | 1½” | 2’ | |

| 13 | 40° F | 1¼” | 1’ | |

| 31 | 20° F | 2” | 3’ | |

807H | 20 | 30° F | 1½” | 2’ | |

| 15 | 40° F | 1¼” | 1’ | |

| 36 | 20° F | 2” | 3’ | |

808H | 24 | 30° F | 1½” | 2’ | |

| 18 | 40° F | 1½” | 1’ | |

| 40 | 20° F | 2” | 3’ | |

809H | 27 | 30° F | 2” | 2’ | |

| 20 | 40° F | 1½” | 1’ | |

| 45 | 20° F | 2” | 3’ | |

810H | 30 | 30° F | 2” | 2’ | |

| 22 | 40° F | 1½” | 1’ |

Figure 18: Safety Relief Valve Installation

25