Table 6: Maximum Capacity of Schedule 40 Pipe in CFH for Gas Pressures of 0.5 psig or Less

Length |

|

| 0.3 Inch w.c. Pressure Drop |

|

|

|

| 0.5 Inch w.c. Pressure Drop | |||||||||||||||

(Feet) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| ½ |

|

| ¾ |

| 1 |

|

| 1¼ |

| ½ |

|

|

| ¾ |

| 1 |

| 1¼ | ||||

10 |

|

| 132 |

|

| 278 |

| 520 |

|

| 1,050 |

| 175 |

|

| 360 |

| 680 |

| 1,400 | |||

20 |

|

| 92 |

|

| 190 |

| 350 |

|

| 730 |

| 120 |

|

| 250 |

| 465 |

| 950 | |||

30 |

|

| 73 |

|

| 152 |

| 285 |

|

| 590 |

| 97 |

|

| 200 |

| 375 |

| 770 | |||

40 |

|

| 63 |

|

| 130 |

| 245 |

|

| 500 |

| 82 |

|

| 170 |

| 320 |

| 660 | |||

50 |

|

| 56 |

|

| 115 |

| 215 |

|

| 440 |

| 73 |

|

| 151 |

| 285 |

| 580 | |||

60 |

|

| 50 |

|

| 105 |

| 195 |

|

| 400 |

| 66 |

|

| 138 |

| 260 |

| 530 | |||

70 |

|

| 46 |

|

| 96 |

| 180 |

|

| 370 |

| 61 |

|

| 125 |

| 240 |

| 490 | |||

80 |

|

| 43 |

|

| 90 |

| 170 |

|

| 350 |

| 57 |

|

| 118 |

| 220 |

| 460 | |||

90 |

|

| 40 |

|

| 84 |

| 160 |

|

| 320 |

| 53 |

|

| 110 |

| 205 |

| 430 | |||

100 |

|

| 38 |

|

| 79 |

| 150 |

|

| 305 |

| 50 |

|

| 103 |

| 195 |

| 400 | |||

Table 7: Equivalent Lengths of Standard Pipe Fittings & Valves |

|

|

|

|

|

|

|

| |||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

Pipe |

|

| I.D. |

|

|

| Valves (Fully Open) |

|

|

|

|

|

| Threaded Fittings |

|

| |||||||

|

|

|

|

|

|

|

|

|

| Swing | 90° |

| 45° |

| 90° Tee, Flow | 90° Tee, Flow | |||||||

Size |

| (Inches) | Gate |

| Globe | Angle |

|

|

| ||||||||||||||

|

|

| Check | Elbow |

| Elbow |

| Through Run | Through Branch | ||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||

½” |

| 0.622 | 0.35 |

| 18.6 | 9.3 |

|

| 4.3 | 1.6 |

| 0.78 |

|

| 1.0 | 3.1 | |||||||

¾” |

| 0.824 | 0.44 |

| 23.1 | 11.5 |

|

| 5.3 | 2.1 |

| 0.97 |

|

| 1.4 | 4.1 | |||||||

1” |

| 1.049 | 0.56 |

| 29.4 | 14.7 |

|

| 6.8 | 2.6 |

| 1.23 |

|

| 1.8 | 5.3 | |||||||

1¼” |

| 1.380 | 0.74 |

| 38.6 | 19.3 |

|

| 8.9 | 3.5 |

| 1.6 |

|

| 2.3 | 6.9 | |||||||

Table 8: Specific Gravity Correction Factors

Specific | Correction | Specific | Correction |

Gravity | Factor | Gravity | Factor |

0.50 | 1.10 | 1.30 | 1.07 |

0.55 | 1.04 | 1.40 | 1.04 |

0.60 | 1.00 | 1.50 | 1.00 |

0.65 | 0.96 | 1.60 | 0.97 |

0.70 | 0.93 | 1.70 | 0.94 |

0.75 | 0.90 | ||

0.80 | 0.87 |

C.Pressure Test. The boiler and its gas connection must be leak tested before placing boiler in operation.

1.Protect boiler gas valve. For all testing over ½ psig, boiler and its individual

2.Locate leaks using approved combustible gas detector, soap and water, or similar nonflammable solution.

WARNING

Do not use matches, candles, open flames, or other ignition source.

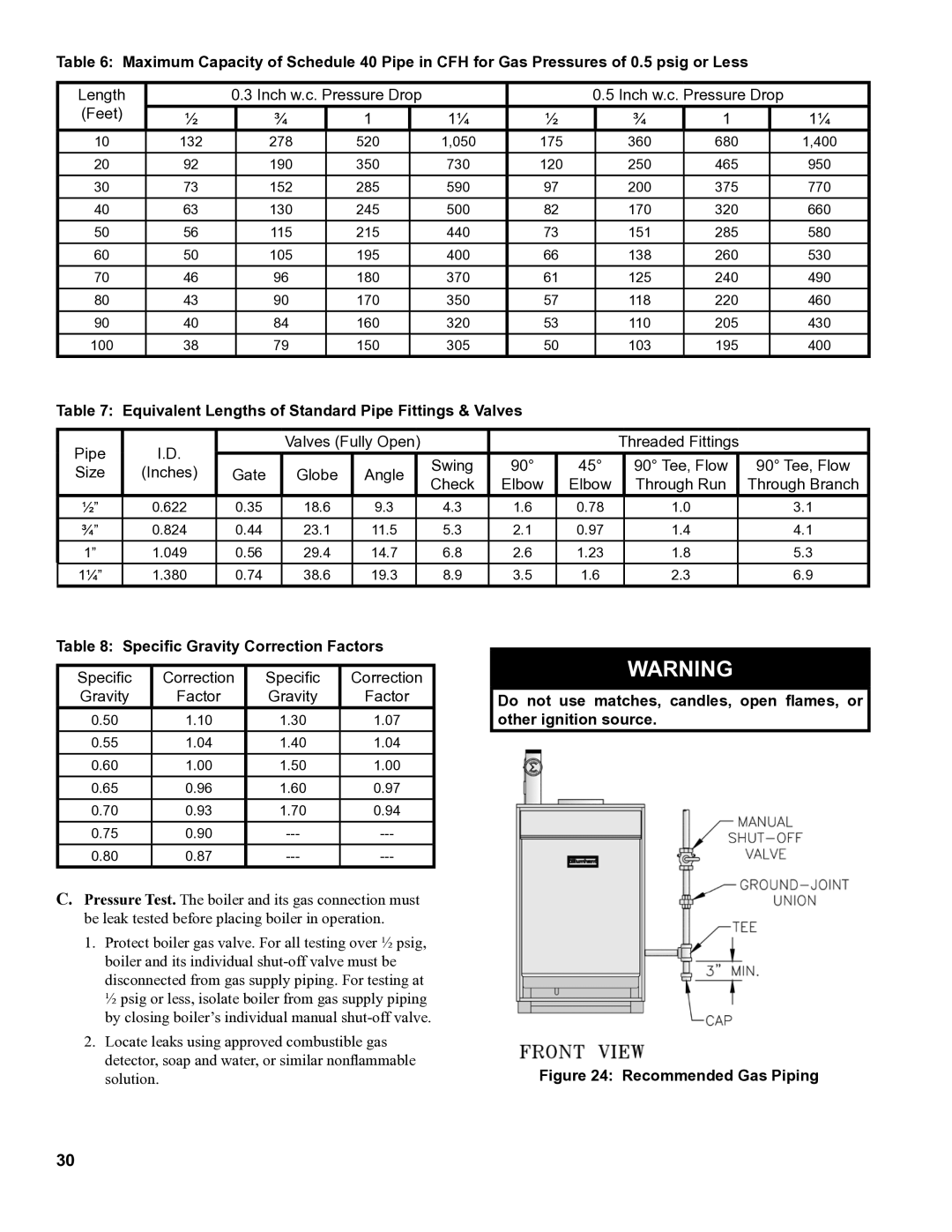

Figure 24: Recommended Gas Piping

30