4.Determine Input Rate. Multiply gas flow rate by gas heating value.

5.Compare measured input rate to input rate stated on rating plate.

a.Boiler must not be overfired. Reduce input rate by decreasing manifold pressure. Do not reduce more than 0.2 inch w.c. If boiler is still overfired, contact your Burnham distributor or Regional Office for replacement Gas Orifices.

b.Increase input rate if less than 98% of rating plate input. Increase manifold gas pressure no more than 0.2 inch w.c. If measured input rate is still less than 98% of rated input:

i.Remove Main Burners per procedure in Section IX: Service.

ii.Remove gas orifices. Drill one (1) drill size larger (drill size is stamped on orifice, or see Key No. 4C in Section X: Repair Parts).

iii.Reinstall gas orifices and main burners. Measure input rate.

6.Recheck Main Burner Flame.

7.Return other gas fired appliances to previous conditions of use.

N. Review User's Information Manual and system operation with owner or operator.

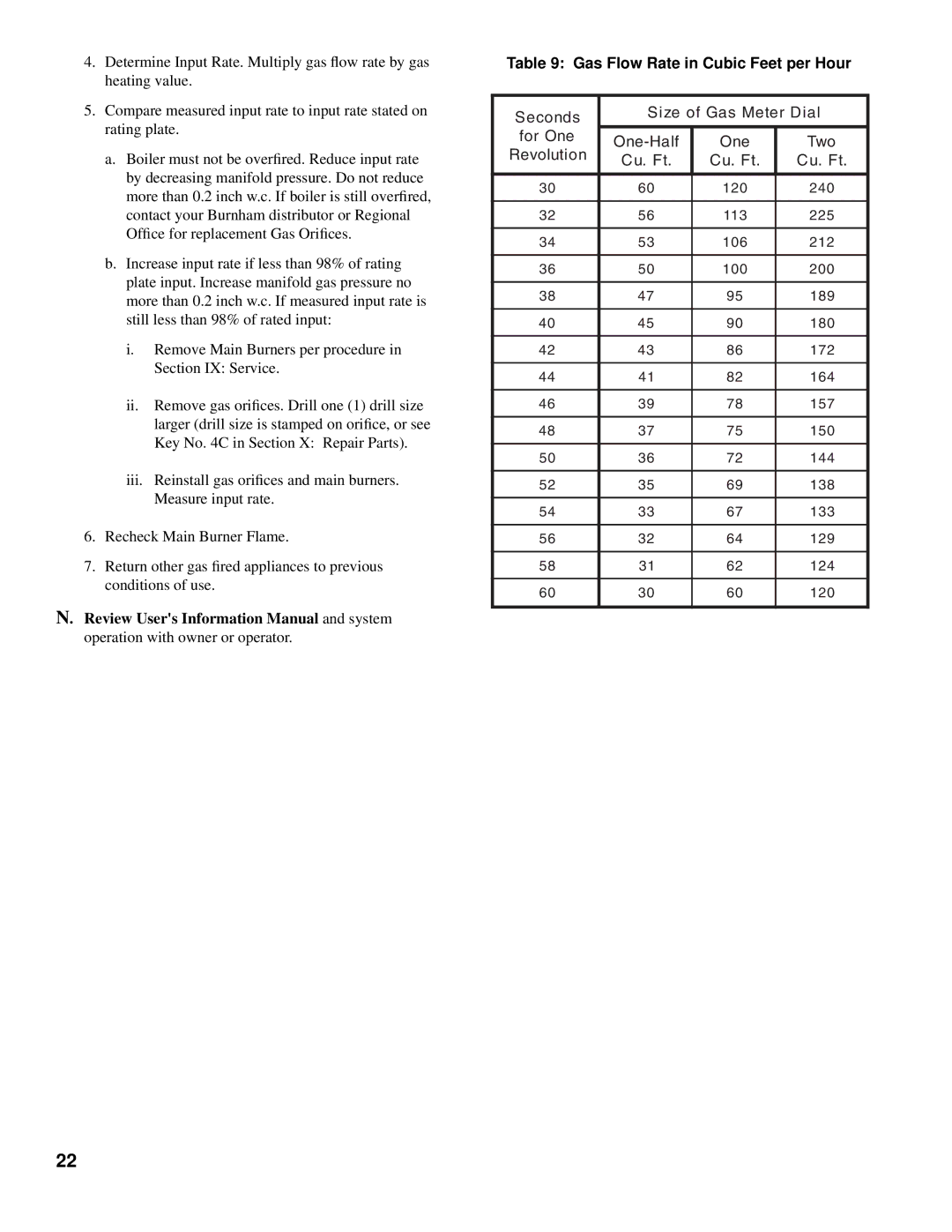

Table 9: Gas Flow Rate in Cubic Feet per Hour

Seconds | Size of Gas Meter Dial | |||

|

|

| ||

for One | One | Two | ||

Revolution | ||||

Cu. Ft. | Cu. Ft. | Cu. Ft. | ||

| ||||

|

|

|

| |

30 | 60 | 120 | 240 | |

|

|

|

| |

32 | 56 | 113 | 225 | |

|

|

|

| |

34 | 53 | 106 | 212 | |

|

|

|

| |

36 | 50 | 100 | 200 | |

|

|

|

| |

38 | 47 | 95 | 189 | |

|

|

|

| |

40 | 45 | 90 | 180 | |

|

|

|

| |

42 | 43 | 86 | 172 | |

|

|

|

| |

44 | 41 | 82 | 164 | |

|

|

|

| |

46 | 39 | 78 | 157 | |

|

|

|

| |

48 | 37 | 75 | 150 | |

|

|

|

| |

50 | 36 | 72 | 144 | |

|

|

|

| |

52 | 35 | 69 | 138 | |

|

|

|

| |

54 | 33 | 67 | 133 | |

|

|

|

| |

56 | 32 | 64 | 129 | |

|

|

|

| |

58 | 31 | 62 | 124 | |

|

|

|

| |

60 | 30 | 60 | 120 | |

|

|

|

| |

22