V. Gas Piping

A.Size gas piping. Design system to provide adequate gas supply to boiler. Consider these factors:

1.Allowable pressure drop from point of delivery to boiler. Maximum allowable system pressure is ½ psig. Actual point of delivery pressure may be less; contact gas supplier for additional information. Minimum gas valve inlet pressure is stamped on the rating label located in the boiler's vestibule compartment.

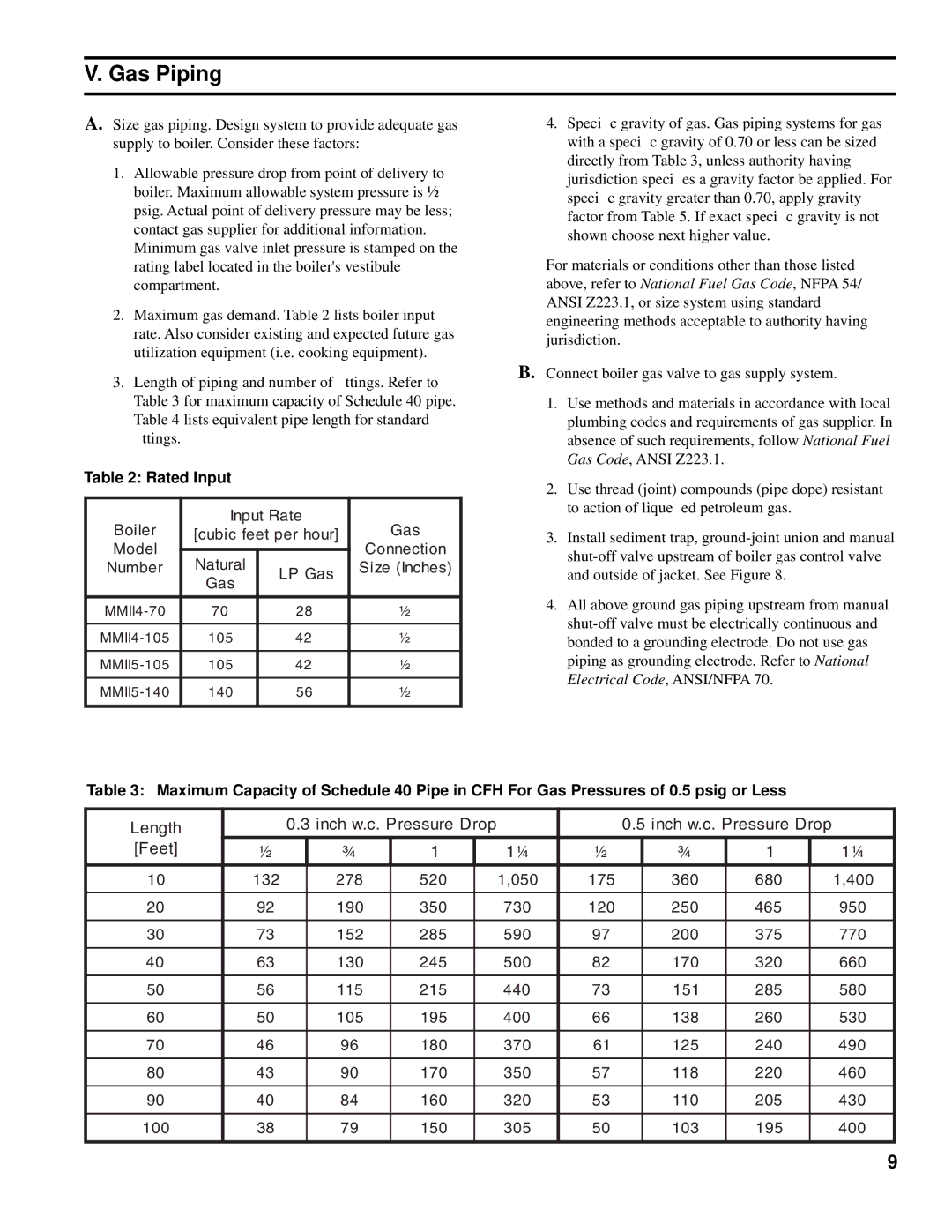

2.Maximum gas demand. Table 2 lists boiler input rate. Also consider existing and expected future gas utilization equipment (i.e. cooking equipment).

3.Length of piping and number of fittings. Refer to Table 3 for maximum capacity of Schedule 40 pipe. Table 4 lists equivalent pipe length for standard fittings.

Table 2: Rated Input

Boiler | Input Rate | Gas | |

[cubic feet per hour] | |||

Model |

|

| Connection |

Natural |

| ||

Number | LP Gas | Size (Inches) | |

| Gas |

| |

|

|

| |

|

|

|

|

70 | 28 | ½ | |

|

|

|

|

105 | 42 | ½ | |

|

|

|

|

105 | 42 | ½ | |

|

|

|

|

140 | 56 | ½ | |

|

|

|

|

4.Specific gravity of gas. Gas piping systems for gas with a specific gravity of 0.70 or less can be sized directly from Table 3, unless authority having jurisdiction specifies a gravity factor be applied. For specific gravity greater than 0.70, apply gravity factor from Table 5. If exact specific gravity is not shown choose next higher value.

For materials or conditions other than those listed above, refer to National Fuel Gas Code, NFPA 54/ ANSI Z223.1, or size system using standard engineering methods acceptable to authority having jurisdiction.

B.Connect boiler gas valve to gas supply system.

1.Use methods and materials in accordance with local plumbing codes and requirements of gas supplier. In absence of such requirements, follow National Fuel Gas Code, ANSI Z223.1.

2.Use thread (joint) compounds (pipe dope) resistant to action of liquefied petroleum gas.

3.Install sediment trap,

4.All above ground gas piping upstream from manual

Table 3: Maximum Capacity of Schedule 40 Pipe in CFH For Gas Pressures of 0.5 psig or Less

Length |

| 0.3 inch w.c. Pressure Drop |

|

| 0.5 inch w.c. Pressure Drop |

| ||||||

[Feet] | ½ |

| ¾ | 1 |

| 1¼ | ½ |

| ¾ | 1 |

| 1¼ |

|

|

|

|

|

|

|

|

|

|

|

|

|

10 | 132 |

| 278 | 520 |

| 1,050 | 175 |

| 360 | 680 |

| 1,400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

20 | 92 |

| 190 | 350 |

| 730 | 120 |

| 250 | 465 |

| 950 |

|

|

|

|

|

|

|

|

|

|

|

|

|

30 | 73 |

| 152 | 285 |

| 590 | 97 |

| 200 | 375 |

| 770 |

|

|

|

|

|

|

|

|

|

|

|

|

|

40 | 63 |

| 130 | 245 |

| 500 | 82 |

| 170 | 320 |

| 660 |

|

|

|

|

|

|

|

|

|

|

|

|

|

50 | 56 |

| 115 | 215 |

| 440 | 73 |

| 151 | 285 |

| 580 |

|

|

|

|

|

|

|

|

|

|

|

|

|

60 | 50 |

| 105 | 195 |

| 400 | 66 |

| 138 | 260 |

| 530 |

|

|

|

|

|

|

|

|

|

|

|

|

|

70 | 46 |

| 96 | 180 |

| 370 | 61 |

| 125 | 240 |

| 490 |

|

|

|

|

|

|

|

|

|

|

|

|

|

80 | 43 |

| 90 | 170 |

| 350 | 57 |

| 118 | 220 |

| 460 |

|

|

|

|

|

|

|

|

|

|

|

|

|

90 | 40 |

| 84 | 160 |

| 320 | 53 |

| 110 | 205 |

| 430 |

|

|

|

|

|

|

|

|

|

|

|

|

|

100 | 38 |

| 79 | 150 |

| 305 | 50 |

| 103 | 195 |

| 400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

9