Operating Instructions and Parts Manual

Model

Modèle CHN50399

Modelo

General Safety Information (Continued)

OPERATOR’S RESPONSIBILITY:

The tool operator is responsible for:

•Reading and understanding tool labels and manual.

•Selecting an appropriate tool actuation system, taking into consideration the work application for which the tool is used.

•The safe use of the tool.

•Ensuring that the tool is used only when the

operator and all other personnel in the work

area are wearing ANSI

Z87 eye protection equipment, and when required, other appropriate protection equipment such as head, hearing and foot protection equipment. Serious eye or permanent hearing loss could result.

•Assuring that the tool is kept in safe working order as described in this manual.

EMPLOYER’S RESPONSIBILITY:

•Selecting an appropriate tool actuation system, taking into consideration the work application for which the tool is used.

•Ensuring that this manual is available to operators and personnel performing maintenance.

•The safe use of the tool.

•Enforcing that the tool is used only when the

operator and all other personnel in the work

area are wearing ANSI

Z87 eye protection equipment, and when required, other appropriate protection equipment such as head, hearing and foot protection equipment. Serious eye or permanent hearing loss could result.

•Assuring that the tool is kept in safe working order as described in this manual.

•Assuring the proper maintenance of all tools in employer’s possession.

•Ensuring that tools which require repair are not further used before repair. Tags and physical segregation are recommended means of control.

●Read and understand

tool labels and manual. ![]() Failure to follow warnings, dangers, and cautions could result in DEATH or SERIOUS INJURY.

Failure to follow warnings, dangers, and cautions could result in DEATH or SERIOUS INJURY.

●Do not use any type of

reactive gases, including, but not

limited to, oxygen and combustible gases, as a power source. Use filtered, lubricated, regulated compressed air only. Use of a reactive gas instead of compressed air may cause the nailer to explode which will cause death or serious personal injury.

●Use only a pressure- regulated compressed

air source to limit the | 90 | |

air pressure supplied to | ||

| ||

the tool. The regulated |

|

pressure must not exceed 90 psi. If the regulator fails, the pressure delivered to the tool must not exceed 200 psi. The nailer could explode which will cause death or serious personal injury.

●Never use gasoline or

other flammable liquids to clean the nailer. Never use the nailer in

the presence of

flammable liquids or gases. Vapors could ignite by a spark and cause an explosion which will result in death or serious personal injury.

Notes Notas

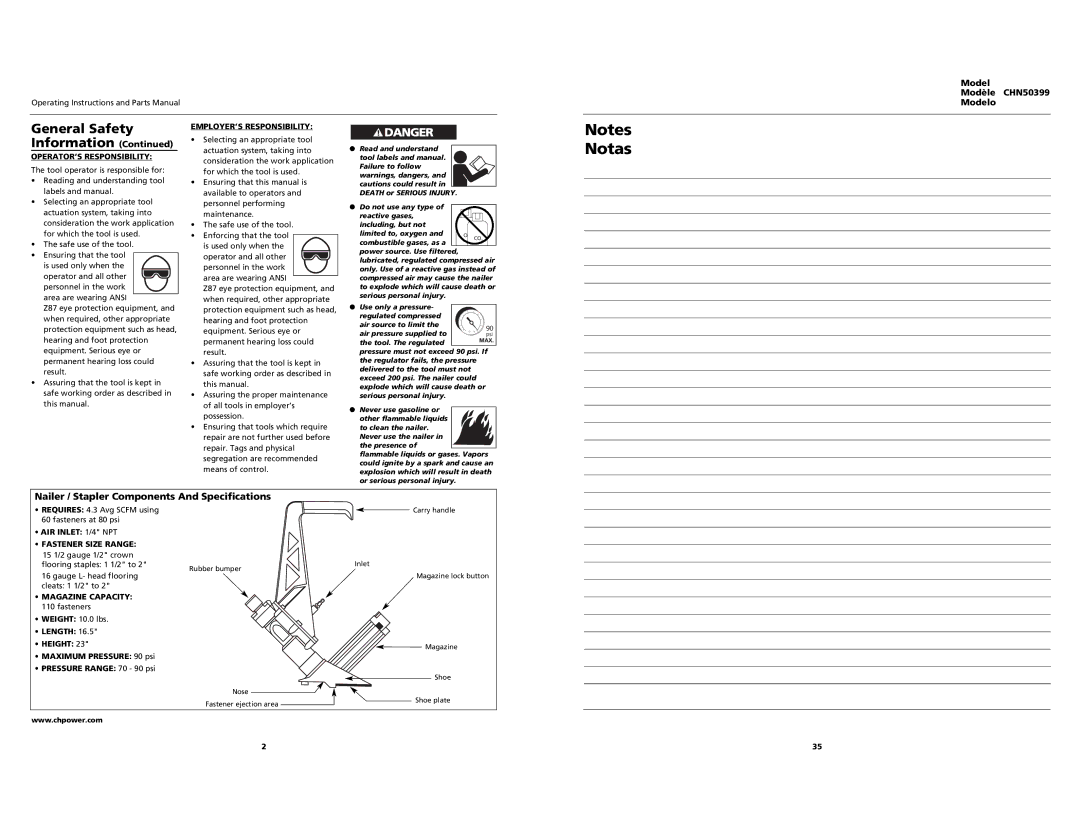

Nailer / Stapler Components And Specifications

•REQUIRES: 4.3 Avg SCFM using 60 fasteners at 80 psi

•AIR INLET: 1/4" NPT

•FASTENER SIZE RANGE:

15 1/2 gauge 1/2" crown flooring staples: 1 1/2" to 2" 16 gauge L- head flooring cleats: 1 1/2" to 2"

•MAGAZINE CAPACITY:

110 fasteners

•WEIGHT: 10.0 lbs.

•LENGTH: 16.5"

•HEIGHT: 23"

•MAXIMUM PRESSURE: 90 psi

•PRESSURE RANGE: 70 - 90 psi

Rubber bumper

Carry handle

Inlet

Magazine lock button

![]() Magazine

Magazine

![]() Shoe

Shoe

Nose ![]()

Fastener ejection area

Shoe plate

www.chpower.com

2 | 35 |