3.Retire la argolla que sujeta a la punta no des- gastable.

4.Coloque cuidadosa- mente la punta no des- gastable

sobre el

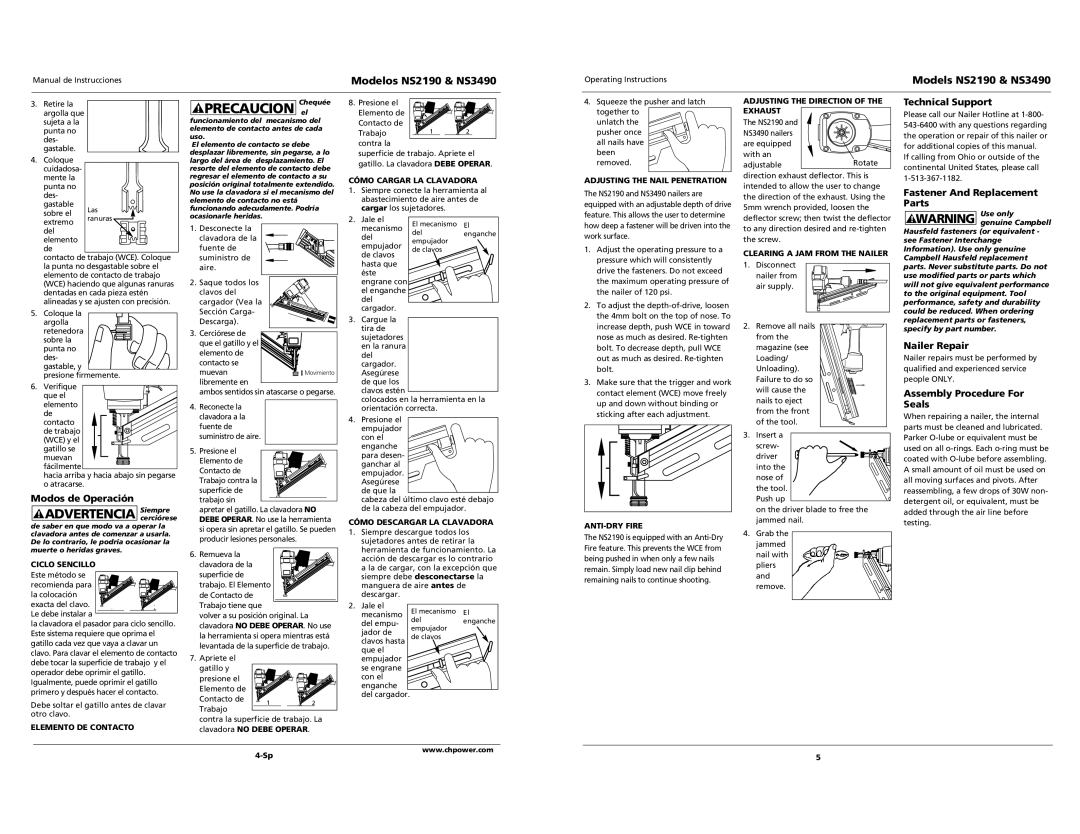

!PRECAUCION Chequéeel

funcionamiento del mecanismo del elemento de contacto antes de cada uso.

El elemento de contacto se debe desplazar libremente, sin pegarse, a lo largo del área de desplazamiento. El resorte del elemento de contacto debe regresar el elemento de contacto a su posición original totalmente extendido. No use la clavadora si el mecanismo del elemento de contacto no está funcionando adecudamente. Podría ocasionarle heridas.

8. Presione el | | |

Elemento de | | |

Contacto de | | |

Trabajo | 1 | 2 |

contra la | | |

superficie de trabajo. Apriete el gatillo. La clavadora DEBE OPERAR.

CÓMO CARGAR LA CLAVADORA

1.Siempre conecte la herramienta al abastecimiento de aire antes de cargar los sujetadores.

4.Squeeze the pusher and latch together to

unlatch the pusher once all nails have been removed.

ADJUSTING THE NAIL PENETRATION

The NS2190 and NS3490 nailers are equipped with an adjustable depth of drive feature. This allows the user to determine

ADJUSTING THE DIRECTION OF THE EXHAUST

The NS2190 and NS3490 nailers are equipped

with an

adjustableRotate direction exhaust deflector. This is intended to allow the user to change the direction of the exhaust. Using the 5mm wrench provided, loosen the

Technical Support

Please call our Nailer Hotline at 1-800- 543-6400 with any questions regarding the operation or repair of this nailer or for additional copies of this manual.

If calling from Ohio or outside of the continental United States, please call 1-513-367-1182.

Fastener And Replacement Parts

Use only

extremo

del elemento

de

contacto de trabajo (WCE). Coloque la punta no desgastable sobre el elemento de contacto de trabajo (WCE) haciendo que algunas ranuras dentadas en cada pieza estén alineadas y se ajusten con precisión.

1.Desconecte la clavadora de la

fuente de suministro de aire.

2.Saque todos los clavos del cargador (Vea la Sección Carga-

2.Jale el mecanismo del empujador de clavos hasta que éste engrane con el enganche del cargador.

El mecanismo El

delenganche empujador

de clavos

how deep a fastener will be driven into the work surface.

1. | Adjust the operating pressure to a |

| pressure which will consistently |

| drive the fasteners. Do not exceed |

| the maximum operating pressure of |

| the nailer of 120 psi. |

2. | To adjust the depth-of-drive, loosen |

| the 4mm bolt on the top of nose. To |

deflector screw; then twist the deflector to any direction desired and re-tighten the screw.

CLEARING A JAM FROM THE NAILER

1. Disconnect nailer from air supply.

! WARNING genuine Campbell |

Hausfeld fasteners (or equivalent - |

see Fastener Interchange |

Information). Use only genuine |

Campbell Hausfeld replacement |

parts. Never substitute parts. Do not |

use modified parts or parts which |

will not give equivalent performance |

to the original equipment. Tool |

performance, safety and durability |

could be reduced. When ordering |

sobre la punta no

des- gastable, y presione firmemente.

6.Verifique que el elemento de contacto de trabajo (WCE) y el gatillo se

muevan fácilmente

hacia arriba y hacia abajo sin pegarse o atracarse.

Modos de Operación

!ADVERTENCIA Siemprecerciórese de saber en que modo va a operar la clavadora antes de comenzar a usarla. De lo contrario, le podría ocasionar la muerte o heridas graves.

| CICLO SENCILLO | | |

| Este método se | | |

| recomienda para | | |

| la colocación | | |

| exacta del clavo. | 1 | 2 |

| Le debe instalar a |

| | |

la clavadora el pasador para ciclo sencillo. Este sistema requiere que oprima el gatillo cada vez que vaya a clavar un clavo. Para clavar el elemento de contacto debe tocar la superficie de trabajo y el operador debe oprimir el gatillo. Igualmente, puede oprimir el gatillo primero y después hacer el contacto.

Debe soltar el gatillo antes de clavar otro clavo.

ELEMENTO DE CONTACTO

Descarga).

3. Cerciórese de | |

que el gatillo y el | |

elemento de | |

contacto se | |

muevan | Movimiento |

libremente en | |

ambos sentidos sin atascarse o pegarse.

4.Reconecte la clavadora a la

fuente de suministro de aire.

5.Presione el Elemento de Contacto de Trabajo contra la superficie de trabajo sin

apretar el gatillo. La clavadora NO DEBE OPERAR. No use la herramienta si opera sin apretar el gatillo. Se pueden producir lesiones personales.

6. Remueva la clavadora de la superficie de

trabajo. El Elemento de Contacto de Trabajo tiene que

volver a su posición original. La clavadora NO DEBE OPERAR. No use la herramienta si opera mientras está levantada de la superficie de trabajo.

| 7. Apriete el | | |

| gatillo y | | |

| presione el | | |

| Elemento de | | |

| Contacto de | 1 | 2 |

| Trabajo |

| | |

contra la superficie de trabajo. La

clavadora NO DEBE OPERAR.

3.Cargue la tira de sujetadores

en la ranura del cargador.

Asegúrese de que los clavos estén

colocados en la herramienta en la orientación correcta.

4.Presione el empujador con el

enganche para desen- ganchar al empujador. Asegúrese

de que la

cabeza del último clavo esté debajo de la cabeza del empujador.

CÓMO DESCARGAR LA CLAVADORA

1.Siempre descargue todos los sujetadores antes de retirar la herramienta de funcionamiento. La acción de descargar es lo contrario a la de cargar, con la excepción que siempre debe desconectarse la manguera de aire antes de descargar.

2.Jale el

mecanismo El mecanismo El

del empu- delenganche

| jador de | empujador |

| de clavos |

| clavos hasta |

| que el | |

| empujador | |

| se engrane | |

| con el | |

| enganche | |

| del cargador. | |

increase depth, push WCE in toward |

nose as much as desired. Re-tighten |

bolt. To decrease depth, pull WCE |

out as much as desired. Re-tighten |

bolt. |

3. Make sure that the trigger and work |

contact element (WCE) move freely |

up and down without binding or |

sticking after each adjustment. |

ANTI-DRY FIRE

The NS2190 is equipped with an Anti-Dry Fire feature. This prevents the WCE from being pushed in when only a few nails remain. Simply load new nail clip behind remaining nails to continue shooting.

2.Remove all nails from the magazine (see Loading/ Unloading).

Failure to do so will cause the nails to eject from the front of the tool.

3. Insert a

screw- driver into the

nose of the tool. Push up

on the driver blade to free the jammed nail.

4.Grab the jammed

nail with pliers and remove.

replacement parts or fasteners, |

specify by part number. |

Nailer Repair

Nailer repairs must be performed by qualified and experienced service people ONLY.

Assembly Procedure For Seals

When repairing a nailer, the internal parts must be cleaned and lubricated. Parker O-lube or equivalent must be used on all o-rings. Each o-ring must be coated with O-lube before assembling. A small amount of oil must be used on all moving surfaces and pivots. After reassembling, a few drops of 30W non- detergent oil, or equivalent, must be added through the air line before testing.