Model WT5000

General Safety (Cont.)

If horizontal stowage is necessary, or an

acetylene cylinder is inadvertently left lying in a horizontal position, it must be placed in an upright position for a minimum of two hours before it can be used. Otherwise, acetone in which the acetylene is dissolved will be drawn out with the gas. By dissolving acetylene in acetone, pressures above 15 PSIG are safely attainable. If enough acetone is removed, the cylinder may become unstable and explode.

●Never tamper with or attempt to repair compressed gas cylinders or valves. Leaking cylinders or cylinders with leaking valves should be placed outdoors, identified and returned to supplier.

Never lift cylinders off the ground by

their valves, caps or with chains or slings.

ADDITIONAL SAFETY STANDARDS

ANSI Standard Z49.1 from American

Welding Society, 550 N.W. LeJune Rd. Miami, FL 33126

Safety and Health Standards

OSHA 29 CFR 1910, from Superintendent of Documents, U.S. Government Printing Office, Washington, D.C. 20402

Safe Handling of Compressed Gases in Cylinders

CGA Pamphlet

Code for Safety in Welding and Cutting

CSA Standard W117.2, from Canadian Standards Association, Standards Sales, 178 Rexdale Boulevard, Rexdale, Ontario, Canada M9W 1R3

Cutting And Welding Processes

NFPA Standard 51B, from National Fire Protection Association, Batterymarch Park, Quicy, MA 02269

Safe Practices For Occupational And Educational Eye And Face Protection

ANSI Standard Z87.1, from American National Standards Institute, 1430 Broadway, New York, NY 10018

Set-Up

equipment should not be used without proper training in safety precautions and procedures by a qualified instructor. Compliance with all federal, state and local regulations is required.

Prior to using this equipment, read all information in the Safety Guidelines. Failure to do so may result in fire, explosion, damage to equipment, severe personal injury or substantial property damage.

GAS CYLINDERS

Gas cylinders with standard CGA fittings are provided with the WT5000 Torch Kit. These empty bottles can be exchanged at your local welding gas supplier for full bottles. The 20 cu. ft. oxygen bottle has a

1.Secure gas cylinders in the tote in the upright position to a stationary support, wall, workbench, post, etc.

2.Inspect the cylinder valve for oil, grease or damaged parts.

Do not use cylinder if oil,

grease or damaged parts are found. Inform gas supplier of this condition immediately.

3.Momentarily open and close the cylinder valve (‘valve cracking’) to dislodge any contaminants in the valve seat area. DO NOT discharge flow of gas at any person or flammable material (see Figure 1).

Figure 1 - Cracking the Cylinder Valve

Do NOT stand

! CAUTION directly in front of the cylinder valve outlet. Always perform valve cracking in a well ventilated area.

4.Carefully inspect the regulators for damaged threads, dirt, dust, grease, oil or other flammable substances. Remove any contaminants with a clean cloth. All acetylene hose connections use

Figure 2 - Regulator Connection

Use the regulator

! CAUTION ONLY with the gas(es) and pressure for which it was intended.

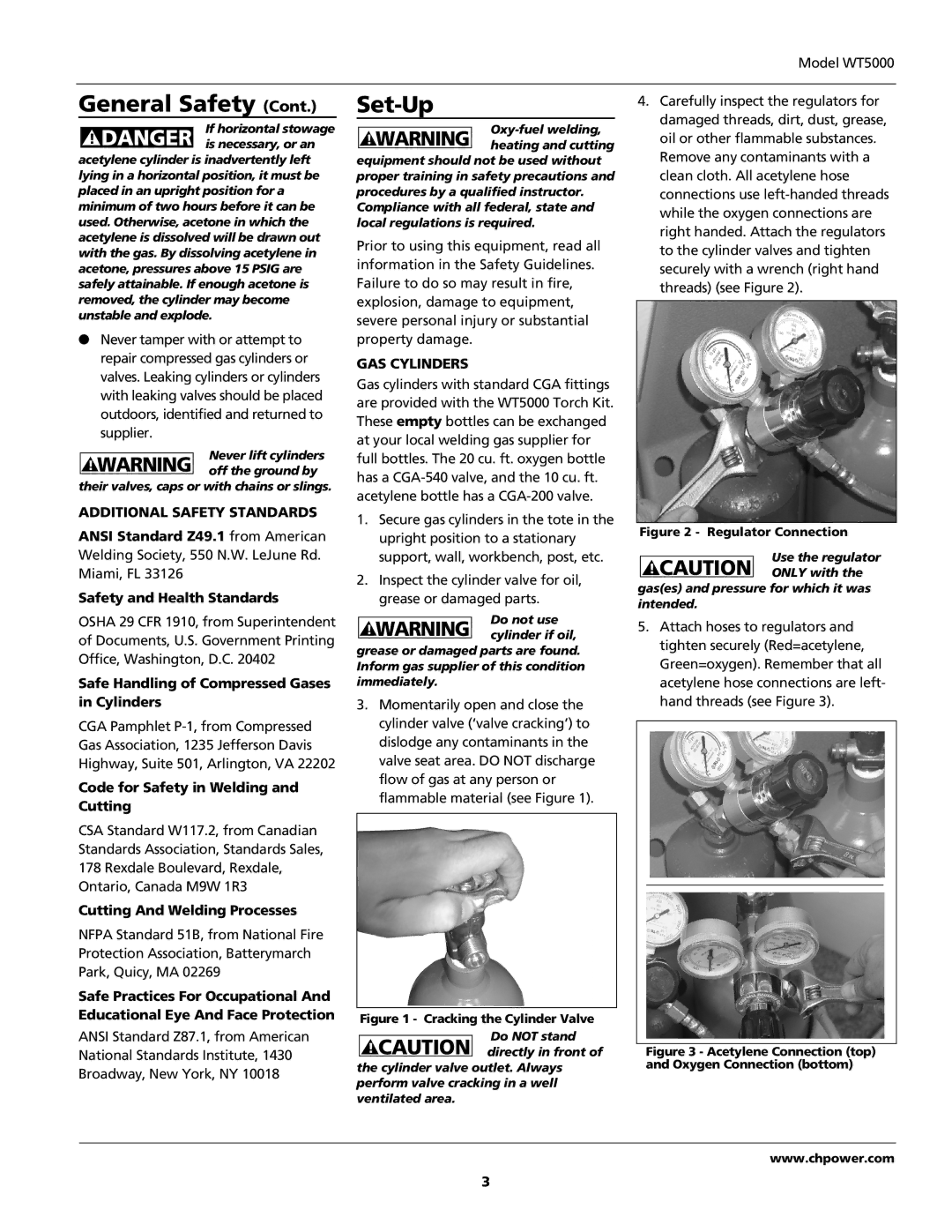

5.Attach hoses to regulators and tighten securely (Red=acetylene, Green=oxygen). Remember that all acetylene hose connections are left- hand threads (see Figure 3).

Figure 3 - Acetylene Connection (top) and Oxygen Connection (bottom)

www.chpower.com

3