Model WT5000

Set-Up (Cont.)

other flammable substances or damaged parts. Have a qualified technician clean handle or repair any damage.

3.Select the proper size and type of welding tip (See Table 1). Inspect the welding tip or cutting attachment for missing

There must be two

(2)

4.For cutting attachment, inspect the tapered seating surfaces on tip and in torch head. Have a qualified technician resurface the seat area if it has dents, burrs or is burned. A poor seating surface may result in backfire or flashback (see Figure 8).

| Do NOT use a tip | |

! WARNING | ||

or torch head that | ||

| ||

|

has damage on the tapered seats.

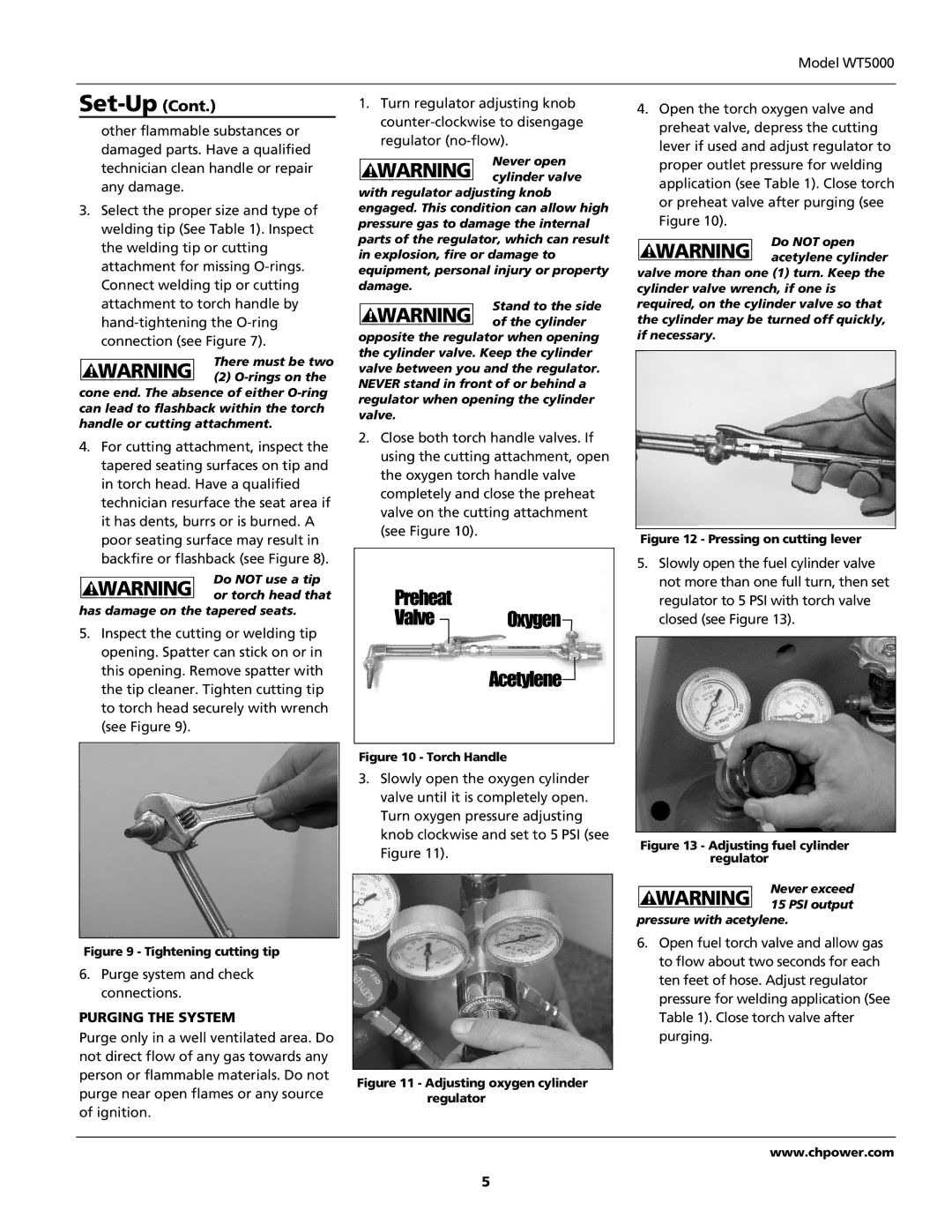

5.Inspect the cutting or welding tip opening. Spatter can stick on or in this opening. Remove spatter with the tip cleaner. Tighten cutting tip to torch head securely with wrench (see Figure 9).

Figure 9 - Tightening cutting tip

6.Purge system and check connections.

PURGING THE SYSTEM

Purge only in a well ventilated area. Do not direct flow of any gas towards any person or flammable materials. Do not purge near open flames or any source of ignition.

1.Turn regulator adjusting knob

Never open cylinder valve

with regulator adjusting knob engaged. This condition can allow high pressure gas to damage the internal parts of the regulator, which can result in explosion, fire or damage to equipment, personal injury or property damage.

Stand to the side of the cylinder

opposite the regulator when opening the cylinder valve. Keep the cylinder valve between you and the regulator. NEVER stand in front of or behind a regulator when opening the cylinder valve.

2.Close both torch handle valves. If using the cutting attachment, open the oxygen torch handle valve completely and close the preheat valve on the cutting attachment (see Figure 10).

Figure 10 - Torch Handle

3.Slowly open the oxygen cylinder valve until it is completely open. Turn oxygen pressure adjusting knob clockwise and set to 5 PSI (see Figure 11).

Figure 11 - Adjusting oxygen cylinder regulator

4.Open the torch oxygen valve and preheat valve, depress the cutting lever if used and adjust regulator to proper outlet pressure for welding application (see Table 1). Close torch or preheat valve after purging (see Figure 10).

Do NOT open acetylene cylinder

valve more than one (1) turn. Keep the cylinder valve wrench, if one is required, on the cylinder valve so that the cylinder may be turned off quickly, if necessary.

Figure 12 - Pressing on cutting lever

5.Slowly open the fuel cylinder valve not more than one full turn, then set regulator to 5 PSI with torch valve closed (see Figure 13).

Figure 13 - Adjusting fuel cylinder regulator

| Never exceed | |

! WARNING | ||

15 PSI output | ||

| ||

|

pressure with acetylene.

6.Open fuel torch valve and allow gas to flow about two seconds for each ten feet of hose. Adjust regulator pressure for welding application (See Table 1). Close torch valve after purging.

www.chpower.com

5