Portable Oxy-Fuel Welding and Cutting Outfit

Set-Up (Cont.)

HOSES

Examine the hoses

! CAUTION carefully before each use. If cuts, burns, worn areas or damaged fittings are found, replace the hose.

Perform the following procedure to clear preservative talc if using a new hose for the first time:

1.Connect the hose to the regulators. Tighten connections securely with wrench.

2.Turn regulator adjusting knobs

3.Slowly open the oxygen cylinder valve until it is completely open.

4.Slowly open the fuel cylinder valve not more than one full turn (see Figure 4).

5.Adjust the oxygen regulator to allow

6.Clear the acetylene hose in the same manner.

Always clear

! CAUTION hoses in a well ventilated area away from any flames or other source of ignition.

Figure 7 - Checking |

SELECTING THE PROPER

ATTACHMENT

Do NOT use the torch handle if

grease, oil or other flammable substances or damage are present! Have a qualified technician clean the torch or repair damage.

1.Attach fuel gas hose (red) to torch valve marked “Fuel” and the Oxygen (green) hose to valve marked “Oxy” (see Figure 6).

2.Inspect torch handle and all apparatus for dust, dirt, grease, oil,

Preheat Gas

Orifices

Tapered

Seating

Surfaces

Oxygen Orifice

Figure 8 - Cutting Tip

Figure 4 - Turning on gas

Figure 5 - Adjusting fuel cylinder valve

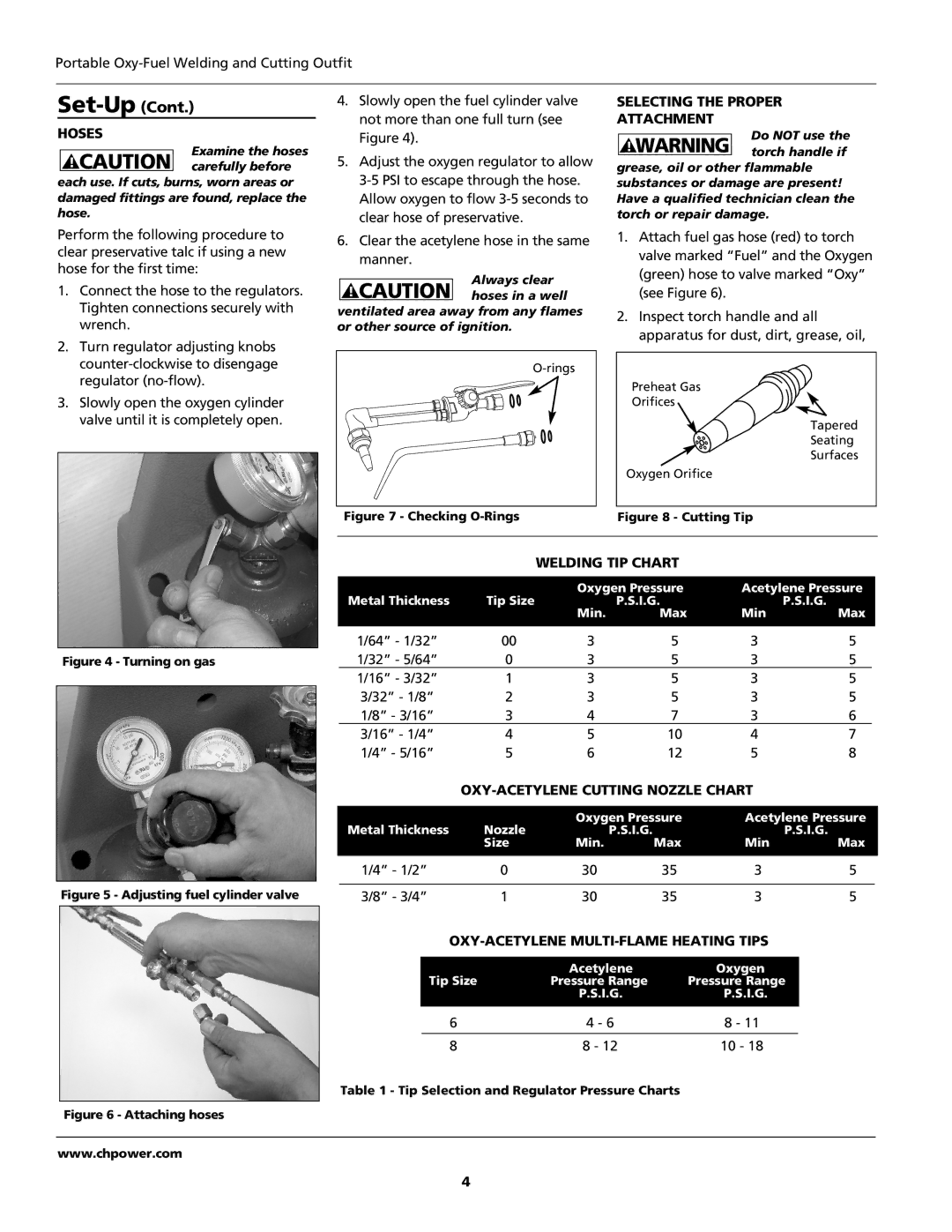

WELDING TIP CHART

|

|

|

| Oxygen Pressure | Acetylene Pressure |

| |||

| Metal Thickness | Tip Size | P.S.I.G. | P.S.I.G. |

|

| |||

|

|

|

| Min. | Max | Min | Max |

| |

|

|

|

|

|

|

|

|

|

|

| 1/64” - 1/32” | 00 | 3 | 5 | 3 |

| 5 |

| |

| 1/32” - 5/64” | 0 | 3 | 5 | 3 |

| 5 |

| |

| 1/16” - 3/32” | 1 | 3 | 5 | 3 |

| 5 |

| |

| 3/32” - 1/8” | 2 | 3 | 5 | 3 |

| 5 |

| |

| 1/8” - 3/16” | 3 | 4 | 7 | 3 |

| 6 |

| |

| 3/16” - 1/4” | 4 | 5 | 10 | 4 |

| 7 |

| |

| 1/4” - 5/16” | 5 | 6 | 12 | 5 |

| 8 |

| |

|

|

|

|

|

| ||||

|

|

|

|

|

|

| |||

|

|

|

| Oxygen Pressure | Acetylene Pressure |

| |||

| Metal Thickness | Nozzle | P.S.I.G. |

| P.S.I.G. |

|

| ||

|

|

| Size | Min. | Max | Min | Max |

| |

|

|

|

|

|

|

|

|

| |

| 1/4” - 1/2” | 0 | 30 | 35 | 3 |

| 5 |

| |

|

|

|

|

|

|

|

|

| |

| 3/8” - 3/4” | 1 | 30 | 35 | 3 |

| 5 |

| |

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| Acetylene |

| Oxygen |

|

|

|

|

| Tip Size | Pressure Range |

| Pressure Range |

|

|

| |

|

|

|

| P.S.I.G. |

| P.S.I.G. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 6 | 4 - 6 |

| 8 - 11 |

|

|

|

|

|

| 8 | 8 - 12 |

| 10 - 18 |

|

|

|

Table 1 - Tip Selection and Regulator Pressure Charts

Figure 6 - Attaching hoses

www.chpower.com

4