2.Connect piping to the indoor section:

a.Shape tube with a tube bender so that the tube ends coincide with flare connections.

b.Carefully remove the flare nut fitting from the indoor seetinn tubing.

c.Thoroughly clean all tubing connection points to pre- vent foreign matter from entering the refrigerant circuit.

d.Thread the 2 fittings by hand, making sure the threads fit smoothly and the flare seats evenly against the union.

e.Tighten the 2 fittings securely. If a torque wrench is used, hold the union side with a wrench and tighten the nut to the specified torque with torque wrench.

See Table 6 for proper tightening torque.

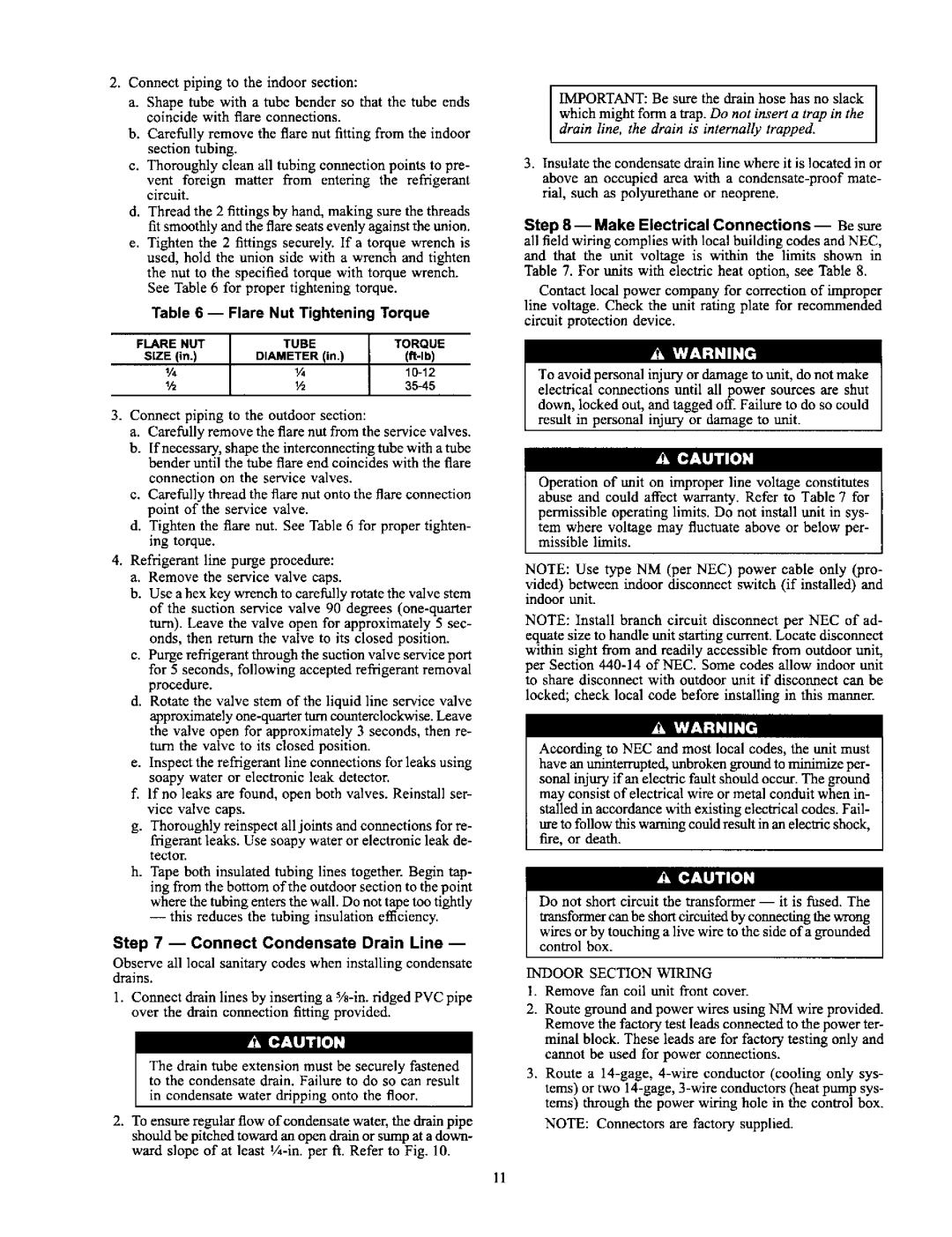

Table 6 --Flare Nut Tightening Torque

FLARE NUT | TUBE | TORQUE |

SIZE (in.) | DIAMETER (in.) | (ff-lb) |

1/4 | 1/4 | 10-12 |

t/= | 1/2 | 35_5 |

3.Connect piping to the outdoor section:

a.Carefully remove the flare nut from the service valves.

b.If necessary, shape the interconnecting tube with a tube bender until the tube flare end coincides with the flare

connection on the service valves.

c.Carefully thread the flare nut onto the flare connection point of the service valve.

d.Tighten the flare nut. See Table 6 for proper tighten- ing torque.

4.Refrigerant line purge procedure:

a.Remove the service valve caps.

b.Use a hex key wrench to earefally rotate the valve stem of the suction service valve 90 degrees (one-quarter turn). Leave the valve open for approximately 5 sec- onds, then return the valve to its closed position.

c.Purge refrigerant through the suction valve service port for 5 seconds, following accepted refrigerant removal procedure.

d.Rotate the valve stem of the liquid line service valve approximately one-quarter turn counterclockwise. Leave the valve open for approximately 3 seconds, then re- turn the valve to its closed position.

e.Inspect the refrigerant line connections for leaks using soapy water or electronic leak detector.

f.If no leaks are found, open both valves. Reinstall ser- vice valve caps.

g.Thoroughly reinspect all joints and connections for re- frigerant leaks. Use soapy water or electronic leak de- tector.

h.Tape both insulated tubing lines together. Begin tap- ing from the bottom of the outdoor section to the point where the tubing enters the wall. Do not tape too tightly -- this reduces the tubing insulation efficiency.

Step 7 --Connect Condensate Drain Line --

Observe all local sanitary codes when installing condensate drains.

1.Connect drain lines by inserting a S/s-in. ridged PVC pipe over the drain connection fitting provided.

!_ [I,_:_ I j i II];

The drain tube extension must be securely fastened to the condensate drain. Failure to do so can result

in condensate water dripping onto the floor.

2.To ensure regular flow of condensate water, the drain pipe should be pitched toward an open drain or sump at a down- ward slope of at least V,-in. per ft. Refer to Fig. 10.

IMPORTANT: Be sure the drain hose has no slack

which might form a trap. Do not insert a trap in the drain line, the drain is internally trapped.

3.Insulate the condensate drain line where it is located in or

above an occupied area with a condensate-proof mate- rial, such as polyurethane or neoprene.

Step 8 -- Make Electrical Connections -- Be sure all field wiring complies with local building codes and NEC, and that the unit voltage is within the limits shown in Table 7. For units with electric heat option, see Table 8.

Contact local power company for correction of improper line voltage. Check the unit rating plate for recommended circuit protection device.

PR ','L'I-'1,'II '[_

To avoid personal injury or damage to unit, do not make electrical connections until all power sources are shut down, locked out, and tagged off. Failure to do so could result in personal injury or damage to unit.

Operation of unit on improper line voltage constitutes abuse and could affect warranty. Refer to Table 7 for permissible operating limits. Do not install unit in sys- tem where voltage may fluctuate above or below per- missible limits.

NOTE: Use type NM (per NEC) power cable only (pro- vided) between indoor disconnect switch (if installed) and indoor unit.

NOTE: Install branch circuit disconnect per NEC of ad- equate size to handle unit starting current. Locate disconnect within sight from and readily accessible from outdoor unit,

per Section 440-14 of NEC. Some codes allow indoor unit to share disconnect with outdoor unit if disconnect can be

locked; check local code before installing in this manner.

r_ VI.__-'_11, It1,

According to NEC and most local codes, the unit must have an uninterrupted, unbroken ground to minimize per- sonal injury if an electric fault should occur. The ground may consist of electrical wire or metal conduit when in- stalled in accordance with existing electrical codes. Fail- ure to follow this warning could result in an eleclric shock, fire, or death.

r!_[t.!_Ij i[*] _1

Do not short circuit the transformer -- it is fused. The

'aansformer can be short c?trcuited by connecting the wrong wires or by touching a live wire to the side of a grounded control box.

INDOOR SECTION WIRING

1.Remove fan coil unit front cover.

2.Route ground and power wires using NM wire provided. Remove the factory test leads connected to the power ter- minal block. These leads ere for factory testing only and cannot be used for power connections.

3.Route a 14-gage, 4-wire conductor (cooling only sys- tems) or two 14-gage, 3-wire conductors (heat pump sys- tems) through the power wiring hole in the control box.

NOTE: Connectors are factory supplied.