|

|

|

| DIRECT RETURN |

|

|

|

|

| REVERSE RETURN |

|

|

|

| REVERSE RETURN | |||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| WITH A COMMON REVERSE | ||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RETURN RISER | |||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

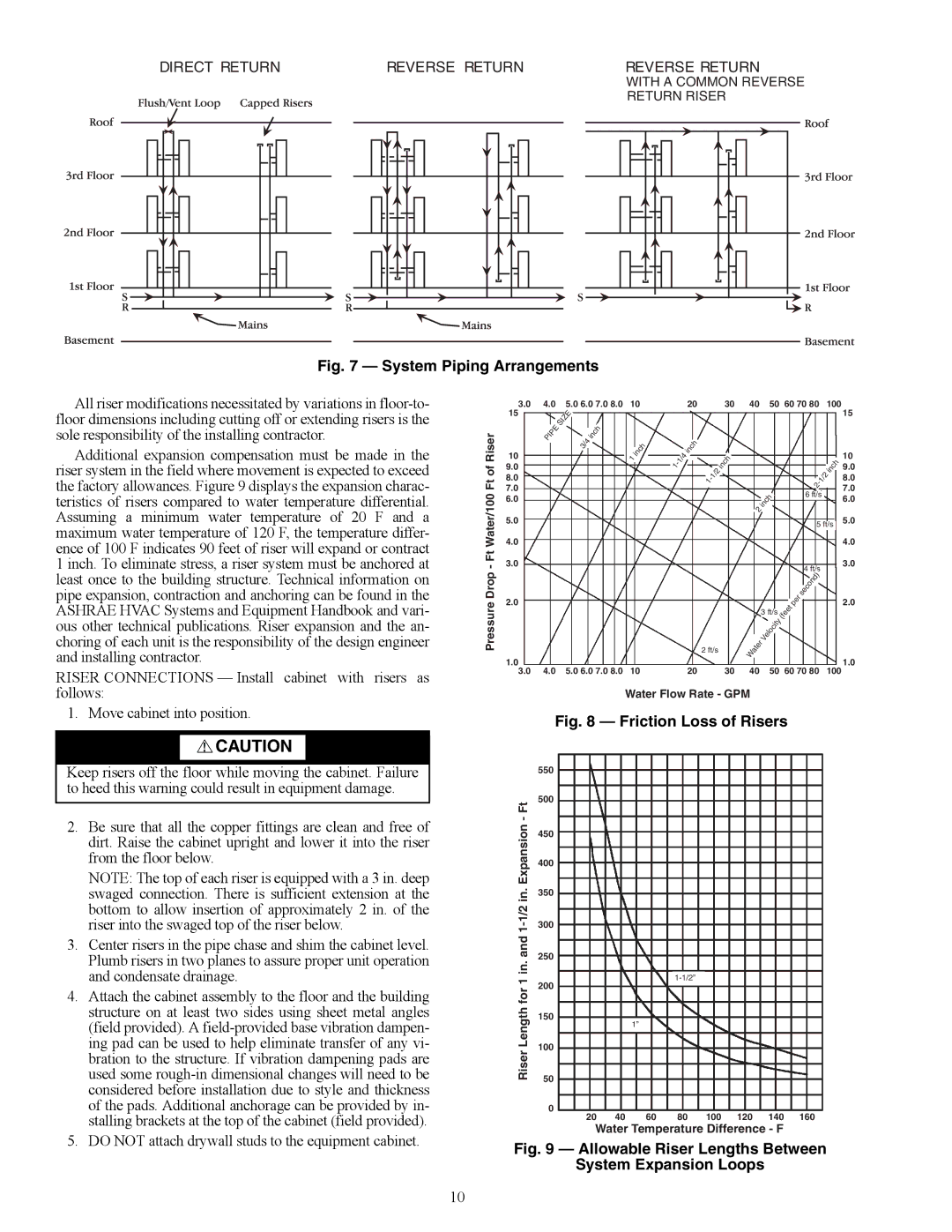

Fig. 7 — System Piping Arrangements

All riser modifications necessitated by variations in

Additional expansion compensation must be made in the riser system in the field where movement is expected to exceed the factory allowances. Figure 9 displays the expansion charac- teristics of risers compared to water temperature differential. Assuming a minimum water temperature of 20 F and a maximum water temperature of 120 F, the temperature differ- ence of 100 F indicates 90 feet of riser will expand or contract 1 inch. To eliminate stress, a riser system must be anchored at least once to the building structure. Technical information on pipe expansion, contraction and anchoring can be found in the ASHRAE HVAC Systems and Equipment Handbook and vari- ous other technical publications. Riser expansion and the an- choring of each unit is the responsibility of the design engineer and installing contractor.

RISER CONNECTIONS — Install cabinet with risers as follows:

1. Move cabinet into position.

Pressure Drop - Ft Water/100 Ft of Riser

3.0 | 4.0 |

| 5.0 6.0 7.0 8.0 | 10 |

| 20 |

| 30 | 40 | 50 | 60 70 80 |

| 100 |

| ||||||||||

15 |

|

| IZE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 15 |

| PIPE | S |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

| inch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| 3 | /4 |

| inch |

| inch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 10 | |||

|

|

|

|

| 1 |

|

| inch |

|

|

|

|

|

|

|

|

|

| inch | |||||

9.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 9.0 | |||||

|

|

|

|

|

|

| 1 |

|

|

|

|

|

|

|

|

|

|

| ||||||

8.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 8.0 | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

7.0 |

|

|

|

|

|

|

|

|

| 1 |

|

|

|

|

|

|

|

|

|

| 7.0 | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2 |

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 6 ft/s |

|

|

| |||

6.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| inch |

|

|

|

|

|

| 6.0 | ||

|

|

|

|

|

|

|

|

|

|

|

|

| 2 |

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

5.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5.0 | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5 ft/s | ||||||

4.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4.0 |

3.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4 ft/s |

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| per | s | econd) |

|

|

|

| |

2.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| (feet |

|

|

|

|

|

| 2.0 | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3 ft/s |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ter | Velocity |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2 ft/s |

| W | a |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

1.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1.0 | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

3.0 | 4.0 |

| 5.0 6.0 7.0 8.0 | 10 |

| 20 |

| 30 | 40 | 50 | 60 70 80 |

| 100 |

| ||||||||||

|

|

| Water Flow Rate - GPM |

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

Fig. 8 — Friction Loss of Risers

![]() CAUTION

CAUTION

Keep risers off the floor while moving the cabinet. Failure to heed this warning could result in equipment damage.

2.Be sure that all the copper fittings are clean and free of dirt. Raise the cabinet upright and lower it into the riser from the floor below.

NOTE: The top of each riser is equipped with a 3 in. deep swaged connection. There is sufficient extension at the bottom to allow insertion of approximately 2 in. of the riser into the swaged top of the riser below.

3.Center risers in the pipe chase and shim the cabinet level. Plumb risers in two planes to assure proper unit operation and condensate drainage.

4.Attach the cabinet assembly to the floor and the building structure on at least two sides using sheet metal angles (field provided). A

5.DO NOT attach drywall studs to the equipment cabinet.

| 550 |

|

|

|

|

|

|

|

- Ft | 500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

sion | 450 |

|

|

|

|

|

|

|

Expan | 400 |

|

|

|

|

|

|

|

in.1/2- | 350 |

|

|

|

|

|

|

|

and 1 | 300 |

|

|

|

|

|

|

|

250 |

|

|

|

|

|

|

| |

in. |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| ||

1 | 200 |

|

|

|

|

|

| |

|

|

|

|

|

|

| ||

th for |

|

|

|

|

|

|

| |

150 |

|

|

|

|

|

|

| |

g |

| 1” |

|

|

|

|

| |

|

|

|

|

|

|

| ||

Len |

|

|

|

|

|

|

| |

100 |

|

|

|

|

|

|

| |

Riser |

|

|

|

|

|

|

| |

50 |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

| 0 | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| 20 | |||||||

| Water Temperature Difference - F |

| ||||||

Fig. 9 — Allowable Riser Lengths Between | ||||||||

System Expansion Loops |

|

| ||||||

10