CHOICE OF BLADE AND SPEED

Your band saw will cut a wide variety of material including wood, wood like products, and nonferrous metals (aluminum, brass, copper).

Note: Inside the front cover of the saw and printed on page 9 in this manual is a blade size label.

•Always usa the correct blade for the material being cut.

•Use a fine tooth blade for cutting thin workpieces when a smooth cut is required, when cutting hard material, or when using lower speeds.

•Always use a blade that will have at least 2 teeth in the material at all times.

•For best results, use thin, narrow blades for tight radius work, and thick, wide blades for large curves and straight cuts.

•Match the approximate blade speed (FPM) to the material being cut.

_1= CAUTION: Do not cut ferrous metals (steel, iron)

n

or hardened steel or serious damage to the saw could result.

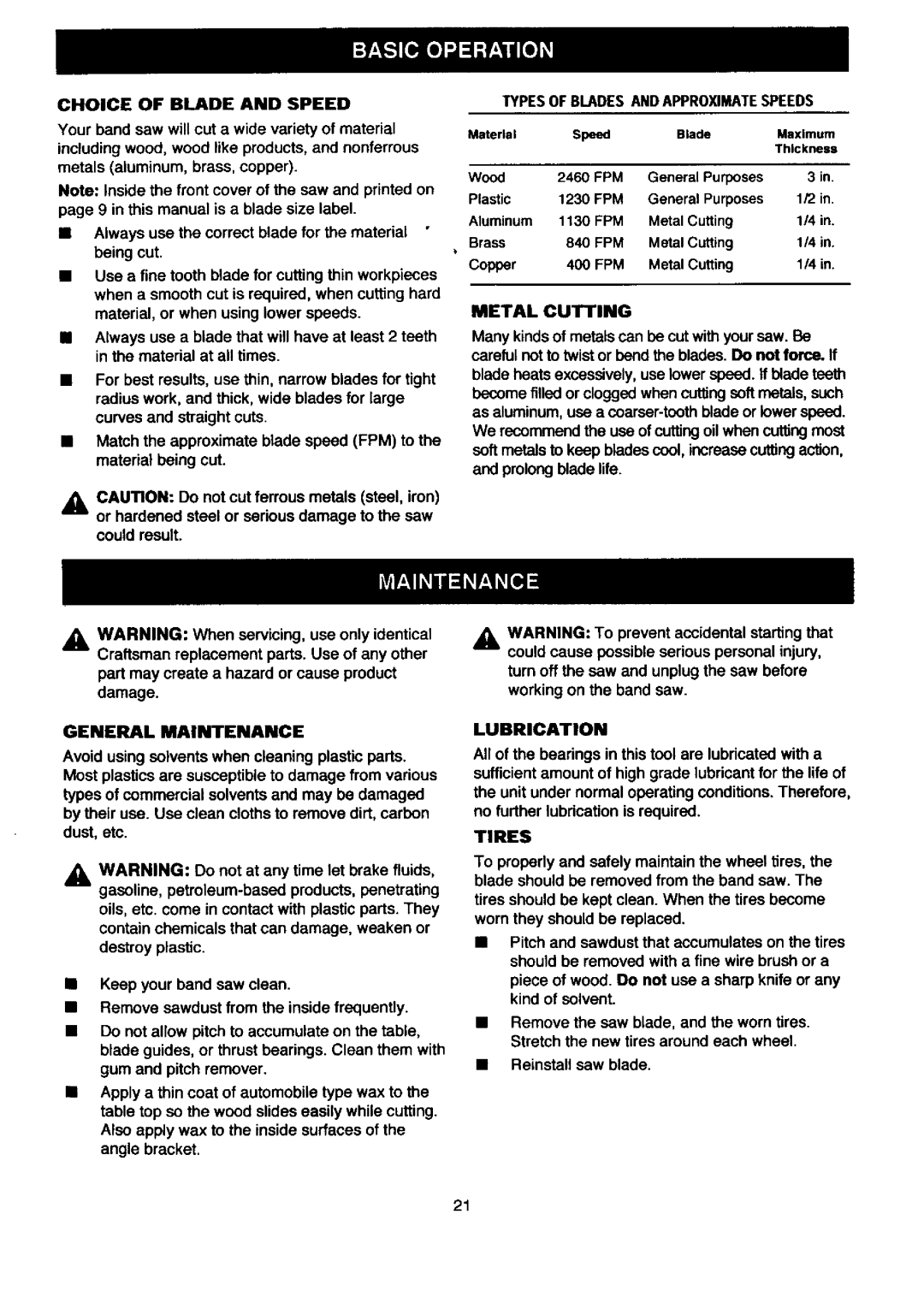

TYPESOF BLADES ANDAPPROXIMATESPEEDS

Material | Speed | Blade | Maximum | ||

|

|

|

|

| Thickness |

Wood | 2460 | FPM | General | Purposes | 3 in. |

Plastic | 1230 | FPM | General | Purposes | 1/2 in. |

Aluminum | 1130 FPM | Metal Cutting | 114 in. | ||

Brass | 840 | FPM | Metal Cutting | 114 in. | |

Copper | 400 | FPM | Metal Cutting | 114 in. | |

METAL CUTTING

Many kinds of metals can be cut with your saw. Be careful not to twist or bend the blades. Do not force. If

blade heats excessively, use lower speed, ff blade tooth become filled or clogged when cut_ng soft metals, such as aluminum, usa a

_i, WARNING: When servicing, usa only identical Craftsman replacement parts. Use of any other

part may create a hazard or cause product damage.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types of commercial solvents and may be damaged by their usa. Use clean cloths to remove dirt, carbon dust, etc.

_1, WARNING: Do not at any time let brake fluids, gasoline,

oils, etc. come in contact with plastic parts. They contain chemicals that can damage, weaken or destroy plastic.

Keep your band saw clean.

Remove sawdust from the inside frequently.

Do not allow pitch to accumulate on the table, blade guides, or thrust bearings. Clean them with gum and pitch remover.

Apply a thin coat of automobile type wax to the table top so the wood slides easily while cutting. Also apply wax to the inside surfaces of the angle bracket.

_i, WARNING: To prevent accidental starting that could cause possible serious personal injury,

turn off the saw and unplug the saw before working on the band saw.

LUBRICATION

All of the bearings in this tool are lubricated with a sufficient amount of high grade lubricant for the life of the unit under normal operating conditions. Therefore, no further lubrication is required.

TIRES

To properly and safely maintain the wheel tires, the blade should be removed from the band saw. The

tires should be kept clean. When the tires become worn they should be replaced.

•Pitch and sawdust that accumulates on the tires should be removed with a fine wire brush or a

piece of wood. Do not usa a sharp knife or any kind of solvent.

•Remove the saw blade, and the worn tires. Stretch the new tires around each wheel.

•Reinstall saw blade.

21