5.Rotate each retaining clip clockwise and press down until it snaps into place over the handle.

Retaining Clip | Handle |

|

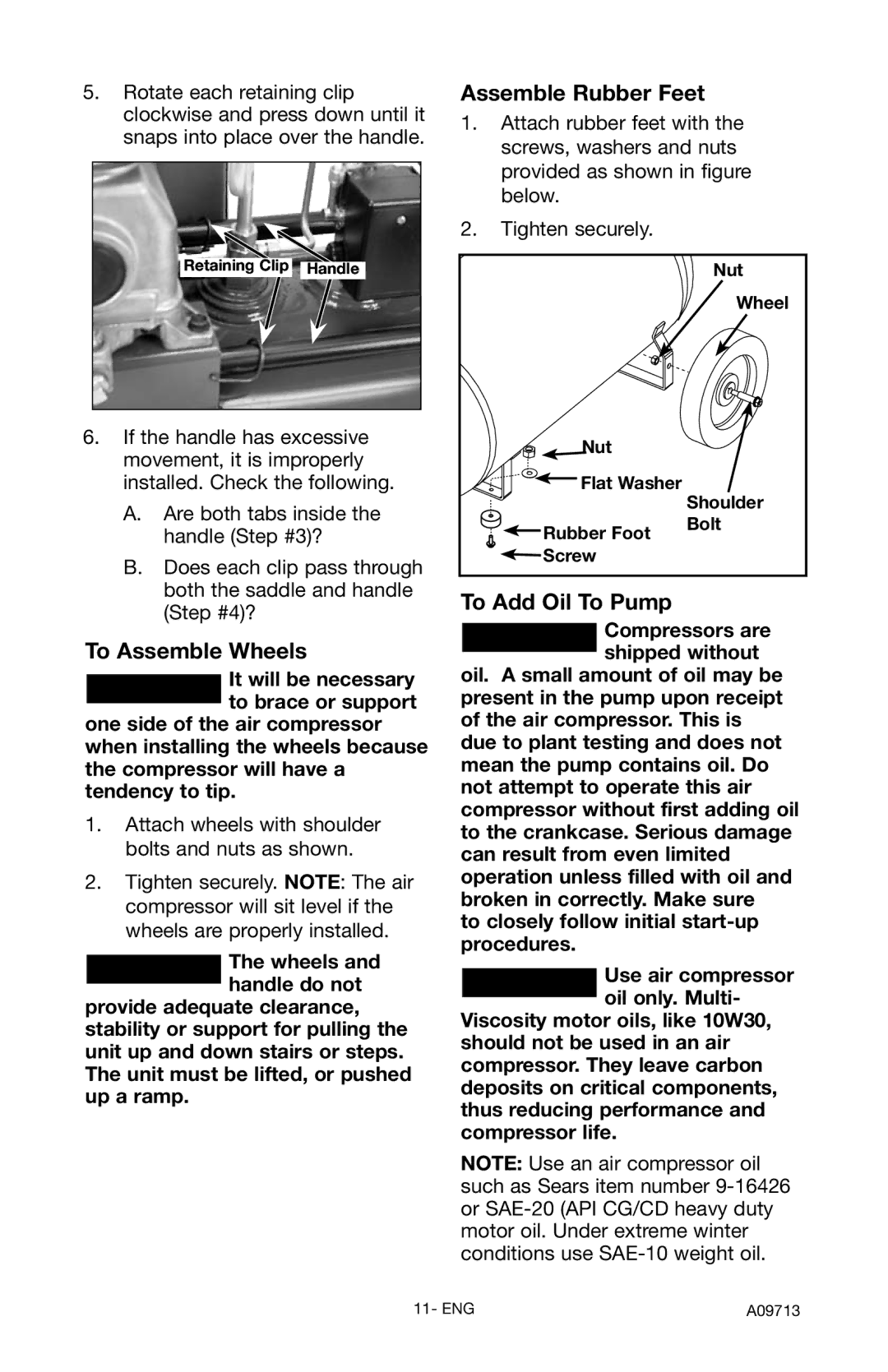

Assemble Rubber Feet

1.Attach rubber feet with the screws, washers and nuts provided as shown in figure below.

2.Tighten securely.

Nut

Wheel

6.If the handle has excessive movement, it is improperly installed. Check the following.

A.Are both tabs inside the handle (Step #3)?

B.Does each clip pass through both the saddle and handle (Step #4)?

To Assemble Wheels

It will be necessary to brace or support

one side of the air compressor when installing the wheels because the compressor will have a tendency to tip.

1.Attach wheels with shoulder bolts and nuts as shown.

2.Tighten securely. NOTE: The air compressor will sit level if the wheels are properly installed.

The wheels and handle do not

provide adequate clearance, stability or support for pulling the unit up and down stairs or steps. The unit must be lifted, or pushed up a ramp.

Nut |

|

Flat Washer | Shoulder |

| |

Rubber Foot | Bolt |

| |

Screw |

|

To Add Oil To Pump

Compressors are shipped without oil. A small amount of oil may be present in the pump upon receipt of the air compressor. This is due to plant testing and does not mean the pump contains oil. Do not attempt to operate this air compressor without first adding oil to the crankcase. Serious damage can result from even limited operation unless filled with oil and broken in correctly. Make sure to closely follow initial

Use air compressor oil only. Multi- Viscosity motor oils, like 10W30, should not be used in an air compressor. They leave carbon deposits on critical components, thus reducing performance and compressor life.

NOTE: Use an air compressor oil such as Sears item number

11- ENG | A09713 |