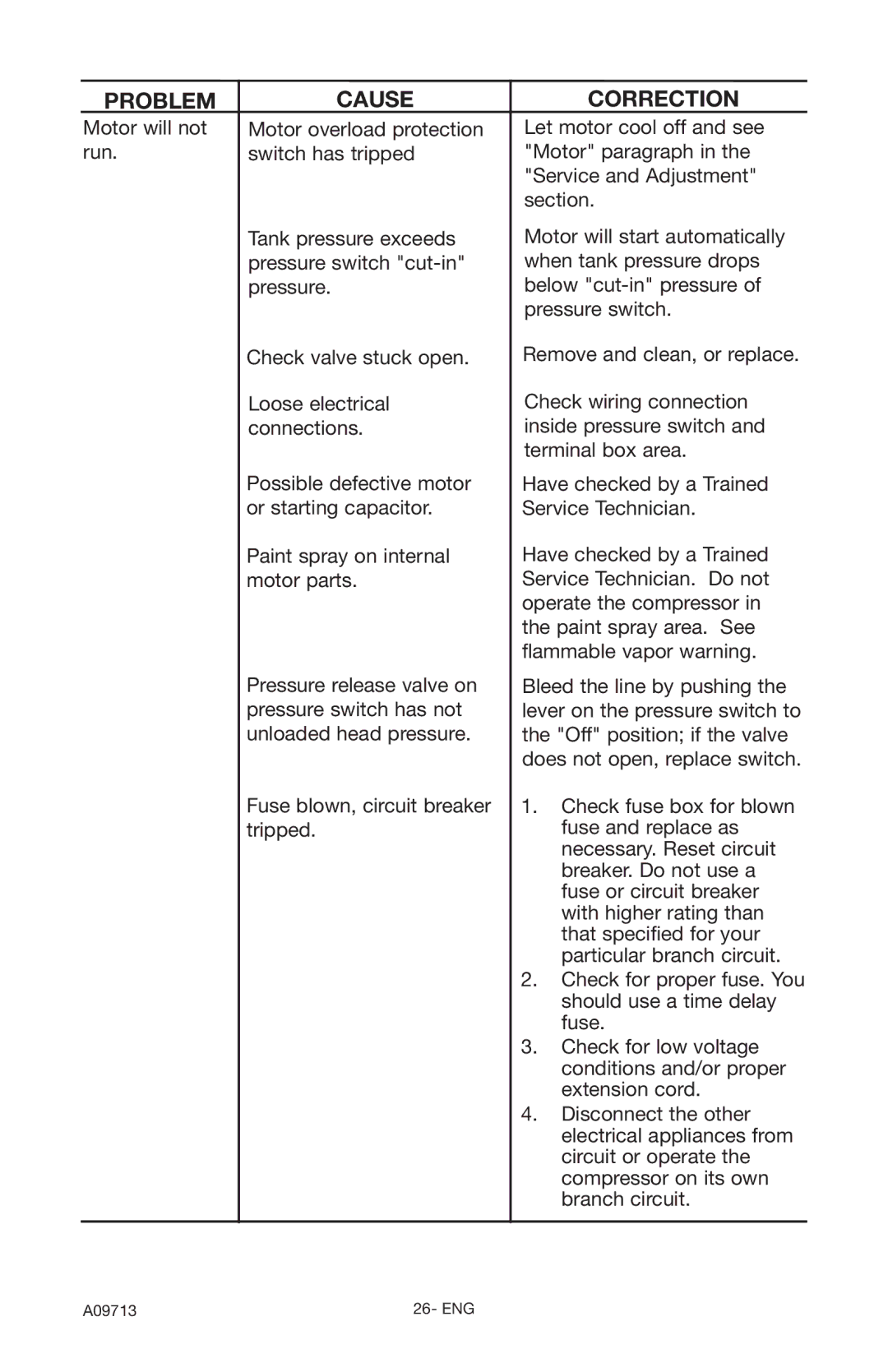

PROBLEM | CAUSE | CORRECTION |

Motor will not | Motor overload protection | Let motor cool off and see |

run. | switch has tripped | "Motor" paragraph in the |

|

| "Service and Adjustment" |

|

| section. |

| Tank pressure exceeds | Motor will start automatically |

| pressure switch | when tank pressure drops |

| pressure. | below |

|

| pressure switch. |

| Check valve stuck open. | Remove and clean, or replace. |

| Loose electrical | Check wiring connection |

| connections. | inside pressure switch and |

|

| terminal box area. |

| Possible defective motor | Have checked by a Trained |

| or starting capacitor. | Service Technician. |

| Paint spray on internal | Have checked by a Trained |

| motor parts. | Service Technician. Do not |

|

| operate the compressor in |

|

| the paint spray area. See |

|

| flammable vapor warning. |

| Pressure release valve on | Bleed the line by pushing the |

| pressure switch has not | lever on the pressure switch to |

| unloaded head pressure. | the "Off" position; if the valve |

|

| does not open, replace switch. |

| Fuse blown, circuit breaker | 1. Check fuse box for blown |

| tripped. | fuse and replace as |

|

| necessary. Reset circuit |

|

| breaker. Do not use a |

|

| fuse or circuit breaker |

|

| with higher rating than |

|

| that specified for your |

|

| particular branch circuit. |

|

| 2. Check for proper fuse. You |

|

| should use a time delay |

|

| fuse. |

|

| 3. Check for low voltage |

|

| conditions and/or proper |

|

| extension cord. |

|

| 4. Disconnect the other |

|

| electrical appliances from |

|

| circuit or operate the |

|

| compressor on its own |

|

| branch circuit. |

|

|

|

A09713 | 26- ENG |