Installation Instructions

Unpacking the Cooker

Unpack the components from inside the grill and oven: Check that the following parts are present.

Grill pan and grid | Grill pan handle |

Baking dish | Pan supports (2) |

Oven shelves (2) | Enamelled discs (4) |

Literature | Brass burner port rings (4) |

Battery 1.5V | Aluminium burner bodies (4) |

Stability Bracket The cooker must be fitted with a stability device firmly secured to the fabric of the building. Ventilation slots at the rear of the cooker

can be used to engage a stability bracket. Keep the bracket clear of controls and pipes on the rear of the cooker.

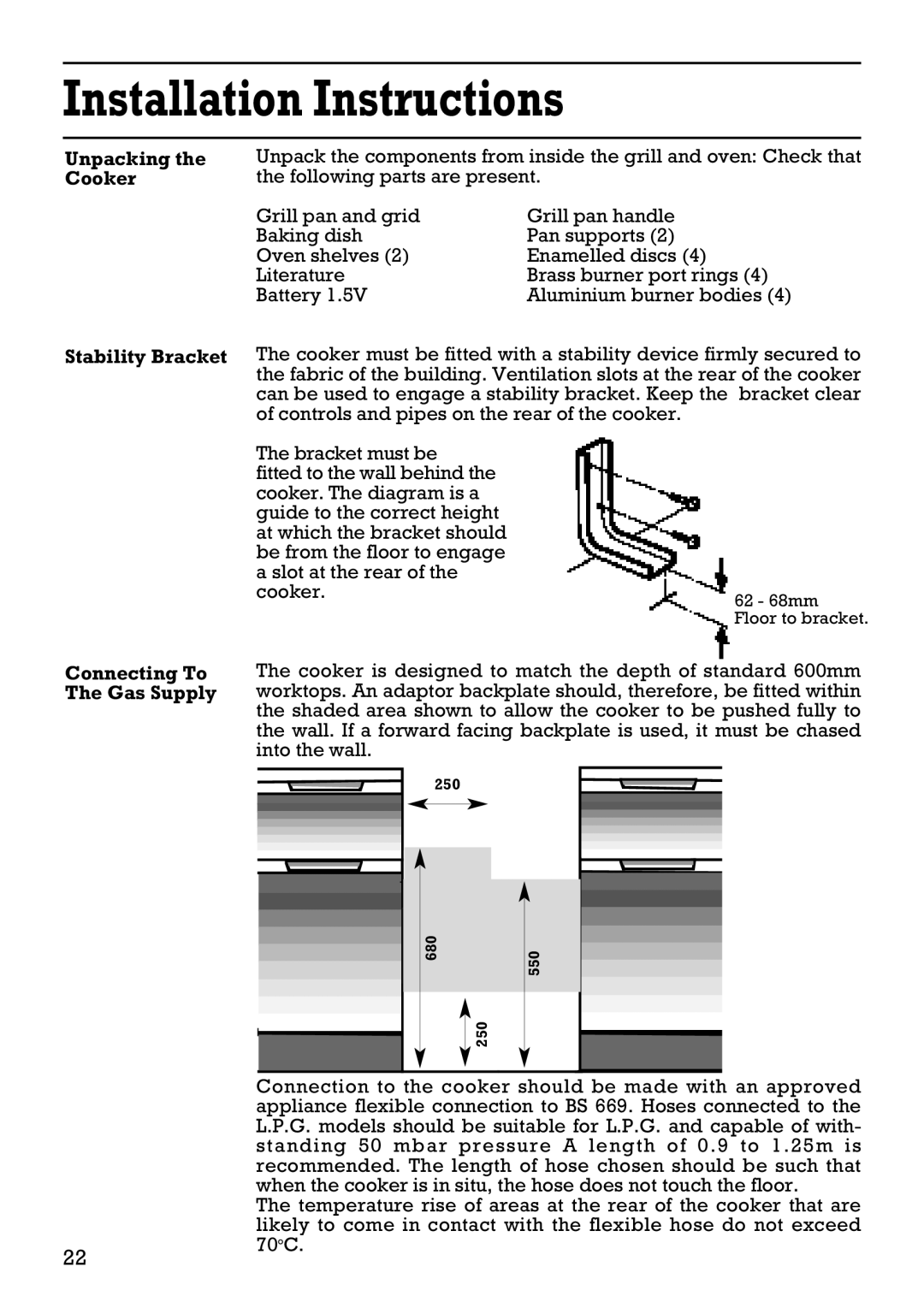

The bracket must be

fitted to the wall behind the cooker. The diagram is a guide to the correct height at which the bracket should be from the floor to engage a slot at the rear of the cooker.

62 - 68mm Floor to bracket.

Connecting To The Gas Supply

22

The cooker is designed to match the depth of standard 600mm worktops. An adaptor backplate should, therefore, be fitted within the shaded area shown to allow the cooker to be pushed fully to the wall. If a forward facing backplate is used, it must be chased into the wall.

250

200

| 680 |

|

|

| 550 |

|

|

|

| ||

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 250 |

|

|

|

|

|

|

| |

|

|

|

|

|

|

Connection to the cooker should be made with an approved appliance flexible connection to BS 669. Hoses connected to the L.P.G. models should be suitable for L.P.G. and capable of with- standing 50 mbar pressure A length of 0.9 to 1.25m is recommended. The length of hose chosen should be such that when the cooker is in situ, the hose does not touch the floor.

The temperature rise of areas at the rear of the cooker that are likely to come in contact with the flexible hose do not exceed 70oC.