SERVICING THE COOLING SYSTEM

Before each use, the engine coolant level in the overflow reservoir should be checked to ensure it is within the operating range. Engine coolant absorbs heat from the engine and transfers the heat to the air flowing through the radiator. If the coolant level becomes low, the engine may overheat and could cause severe damage to the engine.

Use a permanent type antifreeze containing corrosion and rust inhibitors. Dilute the antifreeze with water at a 1:1 ratio to mix the coolant solution (50% antifreeze : 50% water).

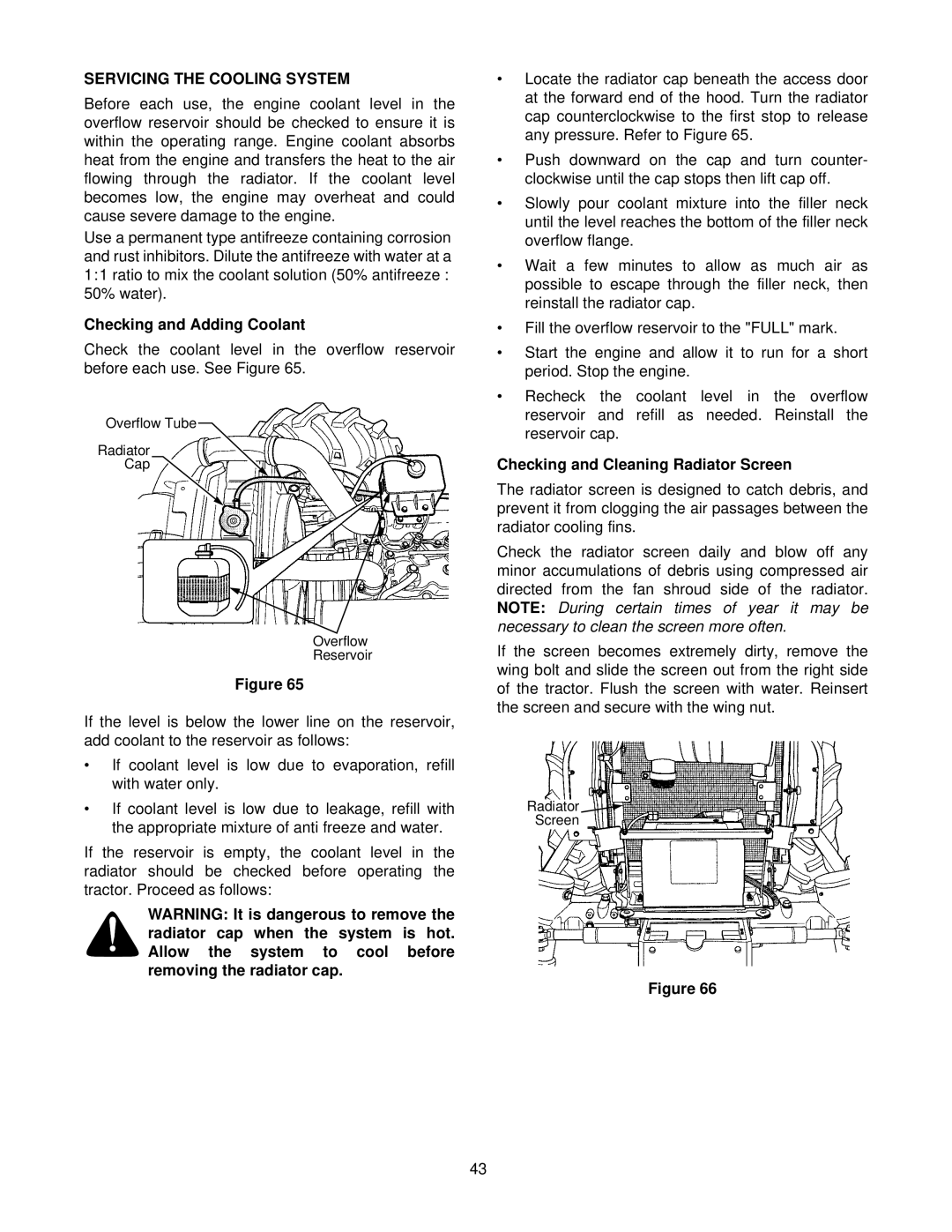

Checking and Adding Coolant

Check the coolant level in the overflow reservoir before each use. See Figure 65.

Overflow Tube

Radiator

Cap

Overflow

Reservoir

Figure 65

If the level is below the lower line on the reservoir, add coolant to the reservoir as follows:

•If coolant level is low due to evaporation, refill with water only.

•If coolant level is low due to leakage, refill with the appropriate mixture of anti freeze and water.

If the reservoir is empty, the coolant level in the radiator should be checked before operating the tractor. Proceed as follows:

WARNING: It is dangerous to remove the radiator cap when the system is hot. Allow the system to cool before removing the radiator cap.

•Locate the radiator cap beneath the access door at the forward end of the hood. Turn the radiator cap counterclockwise to the first stop to release any pressure. Refer to Figure 65.

•Push downward on the cap and turn counter- clockwise until the cap stops then lift cap off.

•Slowly pour coolant mixture into the filler neck until the level reaches the bottom of the filler neck overflow flange.

•Wait a few minutes to allow as much air as possible to escape through the filler neck, then reinstall the radiator cap.

•Fill the overflow reservoir to the "FULL" mark.

•Start the engine and allow it to run for a short period. Stop the engine.

•Recheck the coolant level in the overflow reservoir and refill as needed. Reinstall the reservoir cap.

Checking and Cleaning Radiator Screen

The radiator screen is designed to catch debris, and prevent it from clogging the air passages between the radiator cooling fins.

Check the radiator screen daily and blow off any minor accumulations of debris using compressed air directed from the fan shroud side of the radiator. NOTE: During certain times of year it may be necessary to clean the screen more often.

If the screen becomes extremely dirty, remove the wing bolt and slide the screen out from the right side of the tractor. Flush the screen with water. Reinsert the screen and secure with the wing nut.

Radiator ![]()

![]()

Screen

Figure 66

43