MAINTENANCE

BRUSH INSPECTION

AND REPLACEMENT

DISCONNECT MACHINE FROM POWER SOURCE.

DISCONNECT MACHINE FROM POWER SOURCE.

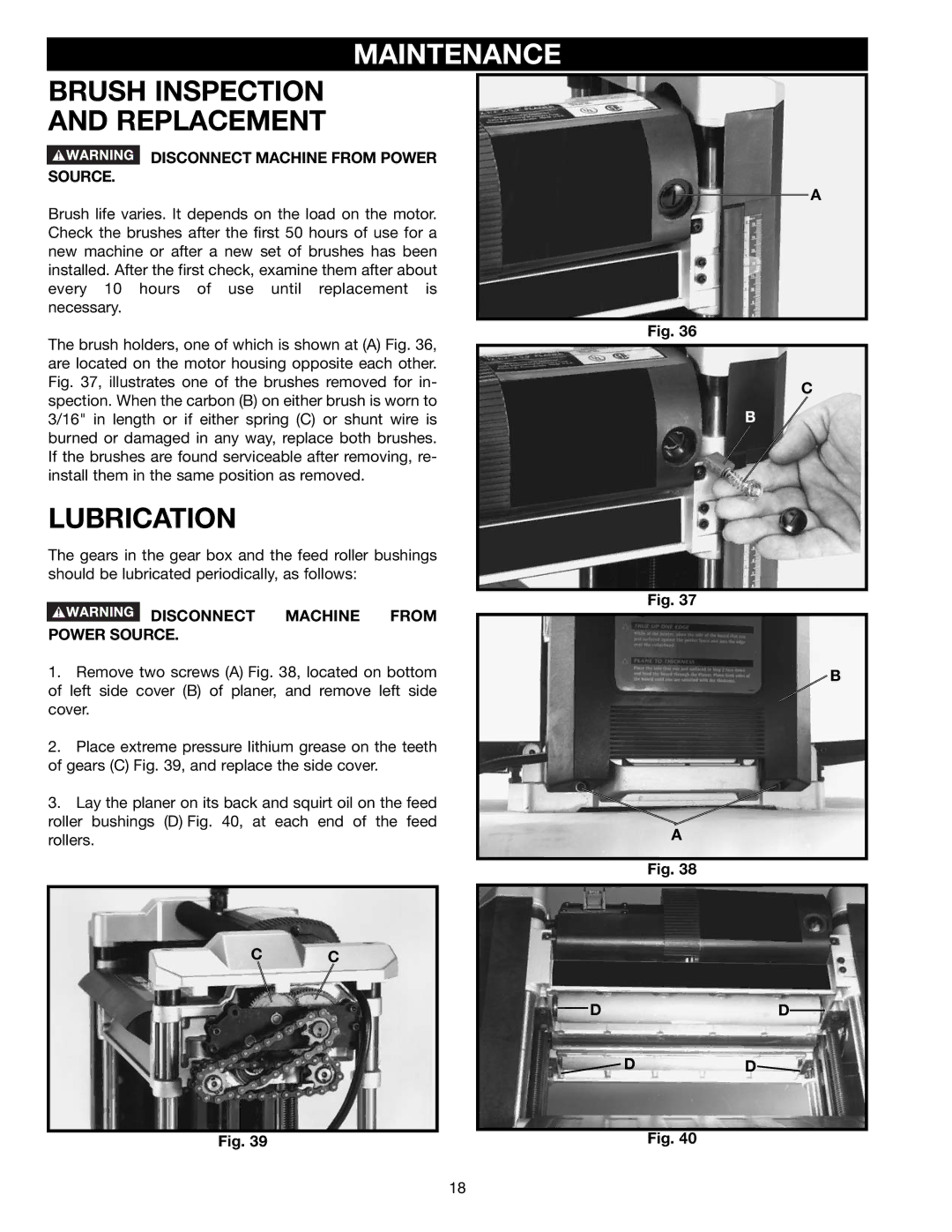

Brush life varies. It depends on the load on the motor. Check the brushes after the first 50 hours of use for a new machine or after a new set of brushes has been installed. After the first check, examine them after about every 10 hours of use until replacement is necessary.

The brush holders, one of which is shown at (A) Fig. 36, are located on the motor housing opposite each other. Fig. 37, illustrates one of the brushes removed for in- spection. When the carbon (B) on either brush is worn to 3/16" in length or if either spring (C) or shunt wire is burned or damaged in any way, replace both brushes. If the brushes are found serviceable after removing, re- install them in the same position as removed.

LUBRICATION

The gears in the gear box and the feed roller bushings should be lubricated periodically, as follows:

A

Fig. 36

C

B

DISCONNECT MACHINE FROM POWER SOURCE.

DISCONNECT MACHINE FROM POWER SOURCE.

1.Remove two screws (A) Fig. 38, located on bottom of left side cover (B) of planer, and remove left side cover.

2.Place extreme pressure lithium grease on the teeth of gears (C) Fig. 39, and replace the side cover.

3.Lay the planer on its back and squirt oil on the feed roller bushings (D) Fig. 40, at each end of the feed rollers.

Fig. 37

![]() B

B

A

Fig. 38

C | C |

|

|

|

|

|

|

|

|

|

|

|

| D | D |

|

|

|

|

|

|

| ||||

|

|

|

|

|

| |||

|

|

|

|

| D | D | ||

|

|

|

|

|

|

|

|

|

Fig. 39 |

|

|

|

|

| Fig. 40 | ||

18